CHEMTROLS INDUSTRIES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CHEMTROLS INDUSTRIES P.LTD.

Prds And Dumpprds

Pressure Reducing and Desuperheating System

PRDS: Pressure Reducing and DeSuperheating System.

Steam PRDS is used for Steam Conditioning Services for reduction of pressure and temperature of steam. It is a combination of Control Valve for the pressure reduction purpose & atomizing nozzles, through which water is sprayed into steam for reducing the temperature.

Split PRDS: separate PRV (Pressure Reducing Valve) and DeSuperheater

Combined PRDS: Both PRV and DeSuperheater in a compact single unit

Combined PRDS helps to save the space and also cost of piping, as the unit is single and compact. For PRDS control system, there will be one Pressure loop and one temperature loop. Pressure control system includes pressure sensor, pressure transmitter, controller, I/P Converter, Pressure gauges, etc. Temperature control system includes temperature sensor, transmitter, controller, I/P Converter, Temperature gauges, etc. Spray water quantity required for the temperature reduction of the steam is controlled by separate spray water valve.

Desuperheaters

Desuperheater Manufacturer

Steam DeSuperheater is used to spray water into steam, so that it gets mixed, resulting in reduction in the temperature at the outlet.

DeSuperheater can be classified into two:

A. Non-Integral type DeSuperheater: DeSuperheater nozzle and water valve are separate units.

B. Integral type DeSuperheater: DeSuperheater is in-built with actuator, so that there is no need of separate spray water valve.

Split PRDS: separate PRV (Pressure Reducing Valve) and DeSuperheater

Combined PRDS: Both PRV and DeSuperheater in a compact single unit

Nozzles are also classified into:

A. Venturi type: where nozzle orifice is fixed irrespective of flow variation.

B. Variable orifice: where orifice area opening will vary according to the flow and pressure variations.

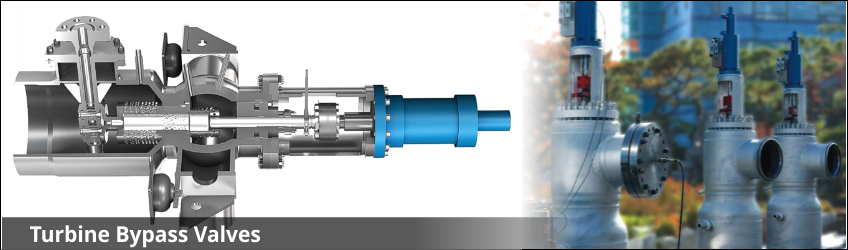

Turbine Bypass Valves

Turbine Bypass Valves Manufacturer

Benefits

PRDS used in turbine bypass applications help to protect the turbine during start-up, power trip and also for part load generation. Turbine by pass valve prevent venting of steam into atmosphere and allow the steam to be dumped into condenser, so that energy can be saved to generate high temperature Boiler Feed Water.

Applications:

Thermal Power Plants and Cogeneration Plants

All process plants like Fertilizers, Petrochemical, Refineries, Pharmaceuticals, Sugar Pulp & Paper, Steel, etc.

Specifications:

Inlet Size: 3" to 20"

Outlet Size: 4" to 64"

Pressure class: ANSI 150# to ANSI 2500#

Material: A182F12 / A182F22 / A182F91 / F92

Rangeability up to 1 : 100

Actuator type: Pneumatic, Hydraulic, Electro-hydraulic, Electric.

Trim type: Multi stage with perforated cage type

Body spherical form, with transitions radially designed with surfaces nearly without marks.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

61153.jpg)

61154.jpg)

61155.jpg)