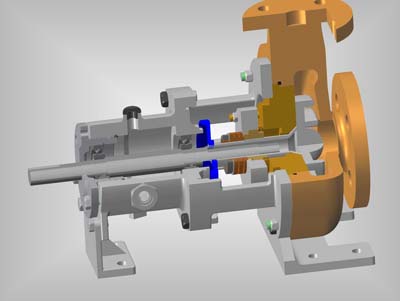

Horizontal Centrifugal Pump Series

HORIZONTAL CENTRIFUGAL CHEMICAL PROCESS PUMP IN FRP MOULDED CONSTRUCTION

CHEMTROL FRP Pump series in India’s FIRST standard pump design non-metallic construction i.e. FRP developed to replace conventional alloy steel, lined and plastic construction pumps.

The lower RPM advantage in our anticorrosive pumps are not there since maintenance is due to corrosion and not due to normal wear and tear. Hence the FRP pumps on 2900 RPM are most economical as compared to other on 1440 RPM. The wetted components of these pumps viz Casing, Casin Back Cover, Impeller, Impeller nut and Gland Pusher are of solid Moulded, Joint less, Composite structures of Fiberglass Reinforce Polyester Resin which ensure excellent resistance to corrosion and abrasion, superior impact resistance and mechanical strength.

Amongst all non-metallic MOC, if we look at physical & mechanical properties, the resistance to corrosion, abrasion, temperature, mechanical strength, the superiority of FRP is proven. Moreover FRP components at times can be repaired unlike any other plastics. FRP is nothing but Fibreglass Reinforced Polyester Resin. Polyester resin being used are of Vinylester grade. Please note that polyester resin being thermo set type of plastic, these resin set permanently. This particular parameter facilitates strength as well as durability to FRP moulded components being incorporated in our FRP moulded pumps. We therefore strongly feel that FRP is the best corrosion resistant / reliable material amongst all plastics. Moreover due reinforcement of Fiberglass, the mechanical strength is better than any other non-metallic material of construction. For your perusal we are enclosing herewith “Physical & Mechanical Properties” of FRP.