Rubber Bellow Seals

Mechanical seals are simply another means of controlling leakage of a process where other means are deemed to be less capable of performing the task adequately. Before the advent of mechanical seals, pump users relied primarily on "rope" or braided style packing to achieve a "seal" around the shaft. A series of pieces or "rings" were installed into the pump "stuffing box" and they were compressed tightly so that they created a difficult leak path for the liquid to negotiate in order to leak to atmosphere.

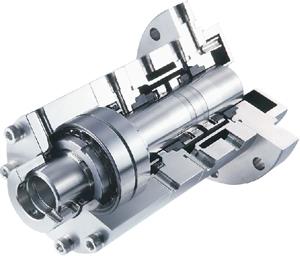

Mechanical seal is a device which is used to avoid leakage at pump, agitator etc. mechanical seals constituted by two sliding faces maintain by an axial forces. Their primary sealing is done by primary sealing ring and it's mating ring. In a properly designed seal they slide relative to each other.

The mechanical seal constitutes:

- Primary sealing ring and mating ring.

- Secondary seals consisting of o-ring or other suitable gasket.

- Hardware consisting mainly of spring and retainer.