BHOOMI RUBBER PROCESSOR

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to BHOOMI RUBBER PROCESSOR

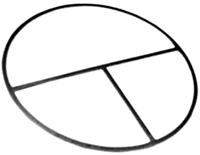

Flange Gasket

A flange gasket is a mechanical seal which fills the space between two mating surfaces of flanges, generally to prevent leakage from or into the joined flanges while under compression. These Gaskets allow "less-than-perfect" mating surfaces on machine parts where they can fill irregularities. We at Bhoomi Rubber, manufacturer Gaskets by moulding process or cutting from Rubber sheets. The material used for manufacturing flange gaskets are Viton, Silicone, Neoprene, Nitrile, Butyl, EPDM, Poly Urethane (PU), natural rubber and Polytetrafluoroethylene (otherwise known as PTFE).

Gaskets for specific applications, such as high pressure steam systems, may contain asbestos. However, due to health hazards associated with asbestos exposure, non-asbestos gasket materials are used when practical.

It is usually desirable that the gasket be made from a material that is to some degree yielding such that it is able to deform and tightly fills the space it is designed for, including any slight irregularities. A few gaskets require an application of sealant directly to the gasket surface to function properly.

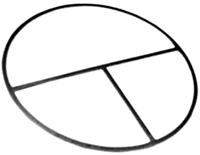

Circular Ring Gasket

Ring gasket is a mechanical seal which fills the space between two mating surfaces. It’s function is similar to flange gasket except that it is applicable for all matting parts in equipments instead of just flanges. Circular Ring Gasket is used generally to prevent leakage from or into the joined parts while under compression. These Gaskets allow "less-than-perfect" mating surfaces on machine parts where they can fill irregularities. We at Bhoomi Rubber, manufacturer Gaskets by moulding process or cutting from Rubber sheets. The material used for manufacturing flange gaskets are Viton, Silicone, Neoprene, Nitrile, Butyl, EPDM, Poly Urethane (PU), natural rubber and Polytetrafluoroethylene (otherwise known as PTFE).

It is defined by outer diameter, inner diameter and thickness of gasket. In general as named it is in plain ring shape without any joint. We at Bhoomi Rubber manufacturer Circular Ring Gasket in single stage moulding or multi stage moulding depending on the size. However ring gasket has varieties of shapes like Round, Square, Rectangular, Oval, etc

Industrial Rubber Gasket

Industrial Gasket has crucial and wide application and huge varieties are required to fulfill these industries. We are one of the leading manufacturers of Industrial Rubber Gasket which are manufactured using quality material and component like in Viton, Silicone, Neoprene, Nitrile, Butyl, EPDM, Poly Urethane (PU), natural rubber and Polytetrafluoroethylene. Bhoomi Rubbersmanufacture these under the strict vigilance of our quality controllers to offer an error free range of Industrial Rubber Gaskets to our customers. Our customers can avail these Gaskets from us in industry leading prices. We also manufacture custom design Industrial Rubber Gaskets.

Various industrial Gaskets are well known on basis of their application and we have the specialty in that. We have huge satisfied clientele in this category. Some of the specialty of Industrial Rubber Gasket is as follows

Pumps Gasket

Valve & Pumps are widely used in industries where malfunction is occurred due to gasket failure. Bhoomi Rubbers provide durable rubber gaskets for valves and pumps. They are available in various rubber for corrosive, noncorrosive, high pressure, low pressure, high temperature, low temperature, slurry fluid, viscous fluid, oil, air, chemical, dyes, vacuum applications. We have developed dies &mould for various standard as well as custom range. We can provide valve or pump gasket in competitive range with quick delivery period by latest technology.

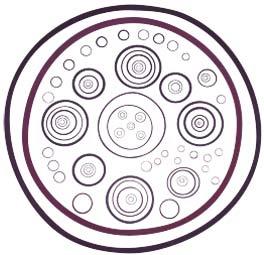

Heat Exchanger Gasket

Heat Exchanger Gasket is a term that has been given to gasket used in heat exchangers. The structure of the gasket or its type varies according to the operating conditions of the exchangers. The heat exchanger gasket come in a wide spectra of tyres including single or double jacketed, corrugated, plain metal, soft and many other. A large selection of different materials allows heat exchangers to operate at temperatures beyond the capabilities of most soft gasket materials. These gaskets are used in shell and tube type heat exchangers. They can be manufactured in very different sizes, shapes, with or without bars. The primary seal is at the inner diameter of the gasket, the outer gasket diameter acts as a secondary seal. The bars seal between the heat exchangers passages. The Heat Exchanger gaskets are produced in several types to meet the most demanding application. Gasket for heat exchangers can be manufactured in metal or alloy with a thickness 0.4mm featuring a soft core inside metallic jacket.

Door Gasket

Door Gasket is widely used in almost all industries. These gaskets are available by moulded process named molded rubber door gasket as well as sponge gasket. In molded process we can achieve Endless Rubber Door Gasket majorly manufactured in silicone material. However we can supply extruded sponge gasket which client can cut and fit in the door as per their requirement. Endless rubber door gasket has to be manufactured in fix size so it is applicable for particular size, and cost effective in high quantity. This also benefits for standardization and easy maintenance of machine is possible. Various cross section for rubber door gasket is available in EPDM, Silicone rubber etc.

Shape for door gasket can be round, square, rectangular and by step molding we can manufacture custom design in any length or diameter. Our dies are precise and high polished to get better finish rubber door gaskets.

Food Grade Gasket

Food Industries is fast growing industry these days. Major eatables are packed one and are manufactured in food grade machineries. Even the appliances are required food grade sealing. Sealing in such applications are made from rubber. The food grade additives are being added while manufacturing raw Food Grade Rubber than the final shape is given to the rubber. Our team takes special care while all process to ensure the rubber is Food grade and samples are tested by laboratories. The varieties of forms & shapes manufactured at Bhoomi such as Food grade Rubber tubes, Food grade Rubber Rings for appliances, Food grade Rubber gasket for Lab equipments, Food Grade Rubber caps and seals for Pharmaceuticals etc.

Custom Molded Rubber Parts

We at Bhoomi Rubber Processor manufacture custom design rubber products. Custom design includes small size to HUGE size, complicated shape, special rubber raw material, step molded and so on. Latest we have manufactured gasket with 10mm X 300mm cross section and 6000mm long and 3000mm width rectangle gasket . We can even manufacture large size than this in any shape like rectangle, round, square etc. Even we have successfully supplied large quantity in short time. We are always ready to take challenges for anything in rubber molding.

Metal Bonding Gaskets

In many applications just rubber is not sufficient to withstand friction or other load. In such case we offer metal bonded or metal inserted rubber gasket. In Metal Bonded Rubber gasket metal is open as per application and balance part is molded with rubber. Some of samples are shown in picture which can give an idea of same. Even in many cases the metal is bonded for giving strength to the product. This increases the life of product and so the life of machinery. We follow proper procedure while manufacturing like increase in area of bonding between metal and rubber, accurate machining of metal part, precise die or mold to avoid excessive rubber. Automobile industries are example for such application where the metal parts are always in contact and rubber part used for high friction. Even in many other industries these gaskets are widely used for metal to metal contact with sealing application.

Metal Inserted Gaskets

Metal inserted gasket differed from metal bonded gasket by non expose of metal. In applications where high strength is required and just rubber is not sufficient, rubber is molded on the metal like m.s., s.s., alloys etc. This increases the life of product and so the life of machinery. We follow proper procedure while manufacturing like increase in area of bonding between metal and rubber, accurate machining of metal part, precise die or mold to avoid excessive rubber. In many industries these gaskets are widely used for sealing application where most wear & tear is expected. Even it gives the strength so that rubber does not bend due inserted metal. Rubber can be used for high friction with low heat generation.

Silicone Tri Clover Gasket

We offer a wide range of Silicone Tri Clover Gasket. Optimum quality food & medical grade silicon rubber is procured for manufacturing this range. Additionally, using 100% pure silicone transparent rubber, we also manufacture unmatched transparent silicone. Moreover, we customize this range in terms of shore hardness, colors, and clamps. Thus, our products are widely used by our clients.

Graphite Ring Gasket

Flexible graphite is manufactured from mineral graphite (expandable flake graphite). It is also called Grafoil® or graphite foil. As its name indicates, flexible graphite is flexible. It is an ideal material for gasketing and sealing applications. It can also be used in many other applications including EMI (electromagnetic interference) shielding & gasketing, heat dissipation, lubrication, stress sensing, vibration damping, and other thermal or electronic or electrochemical applications.

Extruded Products

Bhoomi Rubber Processor , offers a wide range of Silicone Extruded Door Gaskets in more than 3000 different shapes and designs. ( In round and square types)

Bhoomi's Extruded Door Gaskets ( Autoclavable) Gaskets are made from Food-Pharma grade Pure Silicone Rubber which can easily withstands a temperature range of -80°C to +250°C.

Bhoomi's Extruded Gaskets are available in square cross sections like 5mm x 5mm, 8mm x 8mm, 10mm x 10mm, 12mm x 12mm, 20mm x 20mm, 25mm x 25mm, 50mm x 50mm, 100mm x 100mm etc. Hollow OR Solid. These Gaskets are available in Red, White, Orange or any colour as per customer's requirement.

Bhoomi also undertake small and bulk order for these gaskets from 25 Mtrs to 25000 Mtrs.

Bhoomi's Extruded gaskets are manufactured from fully automatic Microwave continuous curing system which ensures accurate dimensional properties, glossy surface finishes and aesthetically beautiful colours.

Tubing

Bhoomi Rubber Processor Is Pioneer In Silicone Transparent Tubings For Food/ Pharma, Chemical, Medical, Heavy Engineering, Thermal Power Stations, And PSUs. These Transparent Tubings Are Made From 100% Pure Silicone Rubber By Using Fully Automatic State-Of-The Art Machineries And Technologies. We Have Already Catering These Products To All The Major Pharmaceutical Companies In India . Our Products Are Also Exported For Overseas Customers.

Bhoomi's Medical Grade Silicone Transparent Tubings Are Manufactured Under Stringent Quality Control And Having The Following Distinguished Features:-

- Made Form Medical Grade Silicone Rubber Which Complied With.

- Temperature Resistant From -80°C To 250°C (-110°F To 480°F)

- Non Reactive To Body Tissue And Fluid

- Non-Adherence To Tissue.

- Unaffected By Most Waster Soluble Materials

- Sterilisable By Steam, Dry Heat, Ethylene Oxide (ET)) And Gamma Radiation

- Resists Oxidation, Ozone And Radiation.

- Indefinite Shelf Life

- Does Not Support Bacterial Growth

Bellows

Bhoomi Rubber Prosseccor Is Pioneer In Rubber Expansion Bellows. Bhoomi's Rubber Expansion Bellows Are Designed To Take Care Of Reactional Forces Like Thermal Expansion, Contraction, Vibrationsetc, Which Otherwise Break Pipelines. These Rubber Expansion Joints Are Made Up Of Neoprene, EPDM, Silicone, Viton And Also In Natural Rubber Etc, Bhoomi's Rubber Expansion Bellows Are Reinforced With Specially Treated Nylon, Rayon,Glass Fiber, Fiber, Steel Cord Etc, By Taking Care Of The Designing For Perfect Balance Between Movements Of Axial, Radial, Torsion And Angular And Pressure Bearing Capacity. Bhoomi's Rubber Expansion Bellows Are Available In Sizes Ranging From 1" NB To 72" NB With Hydro Testing Upto 24-Bar Pressure. These Bellows Are Either Integrated Flange (Metallic Flanges Are Bonded With Rubber) Or Split Back-Up Flanges, And Are Made Strictly As Per The Customer's Design, Drawing And Specification.

Bhoomi's Expansion Joints Are Designed To Alleviate Stresses Caused By Thermal Expansion And Contraction In Piping Systems, Noise And Vibration. Their Flexibility Permits Connecting Misaligned Piping Resulting From Worn Parts, Foundat- Ions Settling And Operation Of System And Mechanical Equipment. Bhoomi'sExpansion Joints Offer Many User Benefits Over Conventional Metal Connectors. They Are Non-Corrosive, Do Not Require Gaskets, Will Not Fatigue, Requires Small Space, Permit Axial, Lateral And Angular Movement, Shock Resistant, Do Not Become Brittle And Eliminate Electrolytic Action.

Silicone Rubber Sheet

SILICONE RUBBER SHEET

ilicone rubber has is a very versatile material by the mere fact that the temperature range is more extreme than other synthetics rubber. The silicone rubber is inert, very flexible and can be used in medical and FDA environments. In addition to temperature, silicone rubber has superior resistance to water and makes an excellent electrical insulator.

We have several types of silicone listed such as the transparent / translucent, FDA and cloth inserted silicone materials.

O Ring

An O-ring, also known as a packing, or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a disc-shaped cross-section, designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface.

The O-ring may be used in static applications or in dynamic applications where there is relative motion between the parts and the O-ring. Dynamic examples include rotating pump shafts and hydraulic cylinder pistons.

O-rings are one of the most common seals used in machine design because they are inexpensive, easy to make, reliable, and have simple mounting requirements. They can seal tens of megapascals (thousands of psi) pressure.

Rubber Rollers

Backed by our team of expert professionals, we are capable of providing our clients with a comprehensive collection of Rubber Rollers. PU coated, our heavy duty rollers are known for their dimensional accuracy, durability, reliability and can withstand adverse environmental conditions. In addition to this, our rollers find their applications in various industries like steel, paper, textile, printing and plastic.

Our rollers have:

- Metal to rubber binding providing applicability

- in high shear and high NIP stresses

- Higher temperature resistance

- Seamless non-marking rubber covering surface

- Abrasion and cut resistance

- Better resistance to chemical attack

- Longer life between re-grinding

- Enhanced consistency

P.T.F.E.

PTFE has been used as a seal in critical operations for close on 50 years. It is undoubtedly the material

of choice for applications that require totally reliable sealing in any environment, from household water systems to the most aggressive and hazardous chemicals. The properties that make PTFE ideally suited

for all sealing applications include:

- Its non-wetting non-stick surface is resistant to enzymatic and microbiological attack and does not enable fungal or bacterial growth

- Its chemically pure and inert state gives unmatched resistance to water, gases, solvents, acids, alkalis and other reactive media

- Its lack of leach-able additives ensures no effect whatsoever on process fluids

- Its resistance to cracking and embrittlement even after long-term use

- Its lubricity prevents the binding and sticking of pipes

- Its retention of these properties over a very wide temperature range, from about -240°C to + 260°C

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.