BALMER LAWRIE AND COMPANY LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to BALMER LAWRIE AND COMPANY LTD.

Leather Chemicals

Description / Specification of Leather Chemicals

We are involved in offering a wide range of Leather Chemicals to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Leather Chemicals. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Greases

Description / Specification of Greases

We are involved in offering a wide range of Greases to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Greases. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Lubricants

Description / Specification of Lubricants

We are involved in offering a wide range of Lubricants to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Lubricants. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Composite Drums

Like a coconut, this composite drum has a double shell. The inner is a blow molded plastic container made from high-density polyethylene to suit your requirements and this is surrounded by a strong outer shell of steel providing unrivalled protection. The plastic lining is perfect for liquids that are incompatible with steel.

It is used for packing dangerous and corrosive liquids such as chemicals and pharmaceuticals. In effect t, the composite drum is plastic container wrapped in steel. This is ideally suited for most liquids, no matter how dangerous or corrosive.

The composite drum is sealed using 50mm buttress threaded plastic plugs, which are tightened into pre-threaded plastic necks of the drums. For additional security, cap-seal can be fitted.

We can provide drums with UN Certification of any category.

FEATURES AND BENEFITS:

Drums are manufactured from the highest quality CRCA steel at the most modern plants.

Drums are subject to Helium Leak Detection to ensure they are 100% leak proof.

Special high quality paints are used for a good quality finish for the drums. High quality customized screen printing is also available to create customer branding.

Triple seam in the drums gives extra strength.

A drain plug provided at the bottom (optional) helps to provide enhanced safety

Drums meet Indian and international shipping specifications

Inclusive transportation for minimum 200 nos. with continuous track of supply.

Internally cleaned drums for chemical companies and other segments.

Balmer Lawrie procures all the raw materials including steel, seaming compounds, closure and paint from reputed suppliers

Provision of UN Certification for hazardous products.

Gaskets are offered depending on product compatibility.

Provision of tag-rings and cap-seals allows increased pilfer-proofness.

Drums are wrapped with corrugated paper/stretch wrap/bubble wrap to avoid transit damage.

Conical Drums

Conical drums are specially developed to satisfy requirements of Food/ Fruits industry. Manufactured from cold rolled closed annealed steel (CRCA), these drums acquire shape through expansion (Plastic Deformation of Metal). This neatly improves the strength of the drum and its mechanical characteristics.

Conical drums are internally coated and externally painted and are available in 210 ltrs, Suitable for filling of 225kg packed aseptic bag.

Due to its structure and dimensions, a conical drum allows exceptional efficiency during transportation and storage. Overall external diameter of the drum makes it possible to store 4 drums in line that suits stuffing of 80 drums in a 20 ft. shipping container. It is also possible to transport up to 1368 empty drums in a 40 ft. Container. Once filled, drums can be stacked 3 to 4 high with the pallets. Conical drums may be returned and reused.

FEATURES AND BENEFITS

Drums are manufactured from the highest quality CRCA steel at the most modern plants.

Drums meet Indian and international shipping specifications

Balmer Lawrie procures all the raw materials including steel, seaming compounds, closures and paint from reputed suppliers.

Reduces cost of transportation and storage due to conical shape, allowing them to nest in.

Reduced storage space.

Perfect palletization and containerization.

Reduced cost of returning the drums by end users since the drums can be nested.

Epoxy phenolic inside lining/ food grade internally painted, in accordance with FDA standards.

Special high quality paints are used for a good quality finish for the drums. High quality customized screen printing is also available to create customer branding.

Drums are wrapped with corrugated paper/stretch wrap/bubble wrap to avoid transit damage.

Non-toxic polish added to the paint, specially recommended by tomato paste packaged in aseptic bags.

Galvanized metallic ring with adjustable lever and security seal to improve the quality.

Lacquered Drums

Lacquered drums are coated internally with epoxy lacquer and are used for the packaging of food, pharmaceuticals, agrochemicals, pesticides, and fine chemicals where purity of the product is of paramount importance. These drums are used when there are possibilities of the product reacting with steel or purity is of utmost importance. The internal coat prevents any reaction whatsoever.

We offer lacquer lined drums duly coated with pigmented lacquer, buff, clear phenolic epoxy lacquer etc. to suit tailor made requirements.

We offer tight head/open head lacquer drums right from 1.00mm thickness to 1.63 mm thickness. They are also available on combination of various steel thickness. We also meet specific requirements of locking rings as per customer requirement.

We can provide drums with UN Certification of any category.

Open Head Plain Drums

Open head drums are used for storing high-density liquids. This packaging allows easy filling and removal of contents. For OH top lid shall be secured to the barrels by a G.I. locking ring and clamped with the help of 100mm long G.I.Bolt & Nut and / or Clamp type G.I. Ring. G.I. locking shall be fabricated from 1.25mm to 1.6mm thick steel.

We offer Open Head Drums right from 0.80mm thickness to 1.25mm thickness. They are also available on combination of various steel thickness.

We can provide drums with UN Certification of any category.

FEATURES AND BENEFITS

Drums are manufactured from the highest quality CRCA steel at the most modern plants.

Special high quality paints are used for a good quality finish for the drums. High quality customized screen printing is also available to create customer branding.

Triple seam in the drums gives extra strength.

Provision of W-bead and corrugation allows enhanced stackability

Drums meet Indian and international shipping specifications

Inclusive transportation for minimum 200 nos. with continuous track of supply.

Internally cleaned drums for chemical companies and other segments.

Balmer Lawrie procures all the raw materials including steel, seaming compounds, closures and paint from reputed suppliers.

Provision of UN Certification for hazardous products.

Gaskets are offered depending on product compatibility.

Provision of tag-rings and cap-seals allows increased pilfer-proofness.

Drums are wrapped with corrugated paper/stretch wrap/bubble wrap to avoid transit damage.

Special internal lining of lacquer or paint as per product needs

Tall Drums

- Drums are manufactured from the highest quality CRCA steel at the most modern plants.

- Drums are subjected to Helium Leak Detection to ensure they are100% leak proof.

- The additional height allows to fill more product and gain a cost advantage as well as logistical convenience.

- Special high quality paints are used for a good quality finish for the drums. High quality customized screen printing is also available to create customer branding.

- Triple seam in the drums give extra strength.

- Provision of W-bead and corrugation allows enhanced stackability

- Drums meet Indian and international shipping specifications

- Internally cleaned drums for chemical companies and other segments.

- Balmer Lawrie procures all the raw materials including steel, seaming compounds, closure and paint from reputed suppliers.

- Provision of UN Certification for hazardous products.

- Gaskets are offered depending on product compatibility.

- Provision of tag-rings and cap-seals allows increased pilfer-proofness.

- Drums are wrapped with corrugated paper/stretch wrap/bubble wrap to avoid transit damage.

Tight Head Plain Drums

- Drums are manufactured from the highest quality CRCA steel at the most modern plants.

- Drums are subjected to Helium Leak Detection to ensure they are100% leak proof.

- Special high quality paints are used for a good quality finish for the drums. High quality customized screen printing is also available to create customer branding.

- Triple seam in the drums give extra strength.

- Provision of W-bead and corrugation allows enhanced stackability

- Drums meet Indian and international shipping specifications

- Inclusive transportation for minimum 200 nos. with continuous track of supply.

- Internally cleaned drums for chemical companies and other segments.

- Balmer Lawrie procures all the raw materials including steel, seaming compounds, closure and paint from reputed suppliers.

- Provision of UN Certification for hazardous products.

- Gaskets are offered depending on product compatibility.

- Provision of tag-rings and cap-seals allows increased pilfer-proofness.

- Drums are wrapped with corrugated paper/stretch wrap/bubble wrap to avoid transit damage.

Composite Repair Services

Our wide range of Composite Repair services are designed to effectively take care of external corrosion related repair & maintenance needs in the Oil & Gas Production and Distribution sectors, chemical plants, Ports & plants in coastal areas, where corrosion is a primary threat.

The Service being provided is in association with IMG composites, UK, a leader in composite repair services & having experience in working with leading Oil & Gas companies across the globe.

Services

Our wide array of offerings include the following

Pipeline Repair Services

Vessel Repair Services

Emergency repairs in running plant.

Benefits

In-Situ repairs.

Minimal plant downtime

Flexibility of repairs.

High durability

Lifetime upto 15 years

Tank Bottom Sludge Processing

Home >

Services >

Tank Bottom Sludge Processing

Services

Composite Repair Services

Lagoon Sludge Processing

Tank Bottom Sludge Process

Sign Up For Updates

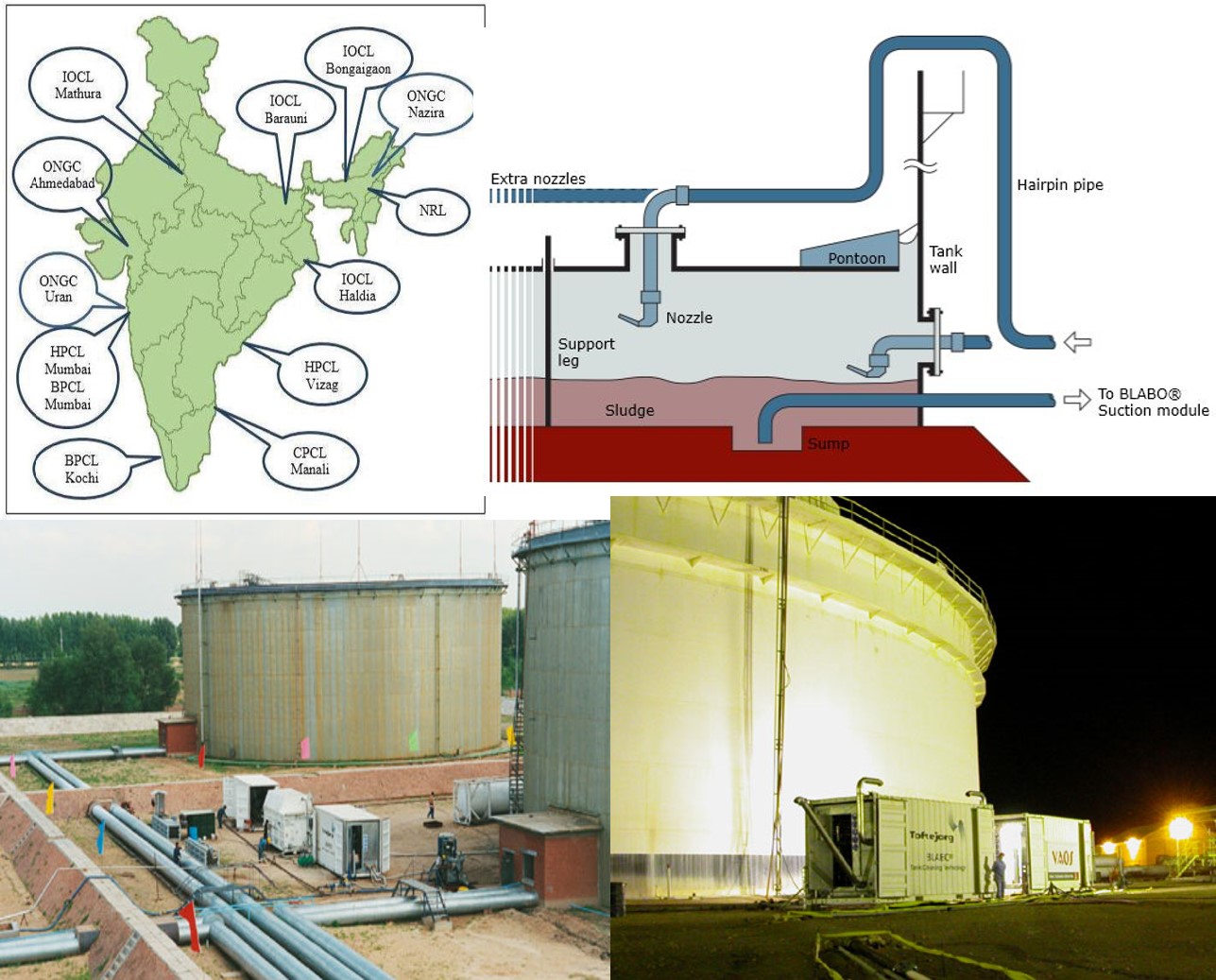

TANK BOTTOM SLUDGE PROCESSING

Our services in the scope of Tank Bottom Sludge Processing & Hydrocarbon Recovery are designed to effectively take care of oily sludge related tank maintenance problems & at the same time, create a substantial value addition opportunity through maximum recovery of trapped hydrocarbon.

Our BLABO process, in association with ORECO, Denmark uses state of the art technology to ensure maximum hydrocarbon recovery, reduced processing time along with utmost compliance to HSE & environmental norms.

Applications:

Oil Refineries.

Oil Installation Assets.

Power Plants.

Benefits:

Guaranteed recovery of up to 90% hydrocarbon content from oily sludge

Up to 60% reduction in tank cleaning time

Environment friendly process

No HSE Risk

Easier tank maintenance after cleaning

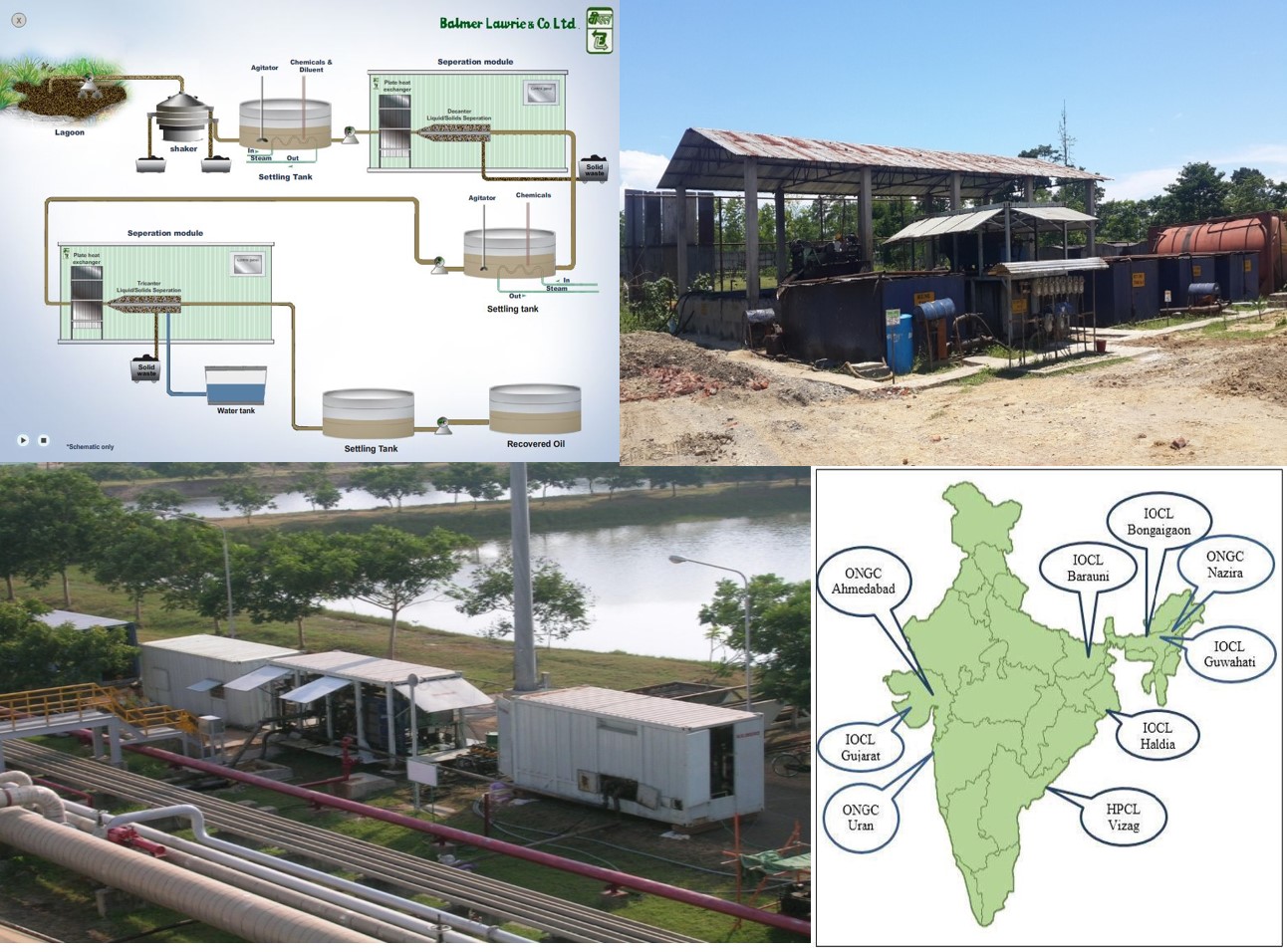

Lagoon Sludge Processing

Our Services for lagoon sludge processing, are designed to effectively tackle the potentially hazardous environmental pitfalls associated with lagoon sludge, ensuring maximum recovery of hydrocarbon & eliminating pollution & HSE issues at site.

BL has developed & adopted a technically advanced method for Lagoon Sludge Processing. The technology is being constantly upgraded & improved upon to enhance efficiency.

We have emerged as forerunners in this field, having processed over 70,000 Kilo Liters of Lagoon Sludge in Refineries, in last 6 years.

Benefits:

Maximum recovery of hydrocarbons

Reduced Processing time.

Environment Friendly Process

No HSE Risk

No Housekeeping Problems

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.