AUTOMATION AND CONTROL (PUNE) P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AUTOMATION AND CONTROL (PUNE) P.LTD.

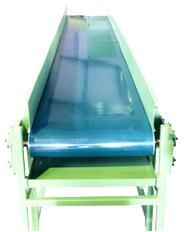

Belt Type Conveyors

We offer special belt type conveyors for general material handling purpose of factories, engineering plants etc. The range includes conveyors for conveying light, medium and heavy loads along different conveying paths like inclination, curve etc. We provide different types of belt conveyors that are available in various materials and dimensions. There are general type of conveyor made as per the requirements of the client.

J Type Hopper Elevator

Our extensive domain expertise assists us in manufacturing 'J' Type Conveyor with Hopper, which require minimum maintenance. This is used for feeding bearing races or round component automatically for any machining operation like grinding, turning or for assembly operation.

Application :- Bearing and Auto Components Industry

Roller Conveyors

Roller conveyors serves to convey pieces-goods horizontally and up or down slightly as powerized and gravity roller conveyors. Fully developed and tried construction techniques make these conveyors a reliable part of any material handling system offering future flexibility and compatibility of equipment. These are general purpose conveyors, made as per client's requirements.

Chip Conveyor

We are very well known name in producing Hot Waste Conveyor / Waste Material Handling Equipment which are perfect for carrying hot waste materials. Used as effective bulk material handling equipment, it is effectively used for handling of waste materials. These are used for transportation of chips from Turning Machines to the outlet in the plant. We can design the Centralized Chip Removal System.

Auto Billet Handling System

We manufacture highly durable (Auto) Billet Handling System for Forging Shop.

This system is used for feeding billets (of various sizes) to Induction Heating Equipments.

These systems are built in various sizes based on clients requirements. The system include following

- Bin Tipper

- Ladder type elevator

- Horizontal Conveyor with orientation

- PLC based Control System

Rotary Hopper

Rotary hopper manufactured by us is a mechanical unit which is used for feeding special components. Single reduction unit drives the main rotating plate, picks up the components while moving upwards. Due to the loading of gravity components, the slot of the rotating plate.

While moving upwards, the mechanism placed on the periphery orient the components. Meanwhile non-oriented components drop back into the hopper area for further lifting. These can be made to work at speed of 80 pieces per min. or more depending upon the shape and orientation needed for the component.

Mounting Machines

We offer clients with Tyres mounting machines and tube mounting machines which are developed and supplied, as per the specific requirements of customers. These units are manufactured right from the concept stage which includes -

- Understanding of customer requirements

- Providing a best suitable solution to such requirements

- Manufacturing such equipment and commissioning the same to customer satisfaction

Radiator Assembly Machines

We offer best quality Core Assembly Machines which fulfill the application demands of diverse industries. Manufactured from highest quality of materials, these Assembly machines are resistant to rust and corrosion and therefore serve the industrial needs for long span of time. Being a customer centric firm, we can custom design these assembly machines as per the demands of our clients. These are semi automatic machines used for Assembly of tubes in the radiator.

Pressing Machines

We offer high quality Phonic Wheel Pressing Machines and Cam Shaft to cater to the requirements of our clients in their related processes. The premium quality machines are durable and capable of sustained high quality performance thus providing our clients with a cost effective and productivity enhancing option.

Application: This SPM is used for Assembly of Phonic Wheel & Cam Shaft

Gantry Robotic System

Automation & Control has successfully designed and supplied Gantry Robotic System for handling 1300C hot billet with weight 150kg. These Gantry Robots are tailor made with special grippers. The Gantry can have X, Y and Z axes, drives with very economical and optimized configuration depending on the type of the object to be handled.

Auto Loading And Unloading Systems

We provide Tappet Valve Automation on Lapping Machine. We offer standard & high quality automation facility to suit customer’s automation needs. We execute our automation systems at cost effective prices within the stipulated time. Over the years we have gained a strong place in this area. These systems are designed for loading & unloading of components to any specific machine like grinding machine, lapping machine or for any other operation.

Belt Type Washing Machine

Our wide assortment of belt type washing machines are manufactured from premium quality raw material. It is S.S. wire mesh (belt type) conveyorised washing machine which finds usage in washing of components. Known for their durability and high performance, these can be customized as per the specifications of our customers.

Industrial Washing Machine

We offer clients Industrial Washing Machines like shower type washing machines & nozzle type washing machines which are manufactured from premium quality raw material. These are used to wash components after each machining operation. This removes burr, oil and prevents dust from getting collected on component.

Brush Washing Unit

We offer precision engineered brush washing units which ensures a consistent washing quality. This unit has an inline washing machine which is used to wash mirrors after profile cutting and polishing. These units can also be offered in customized options, as per the requirements of our customers.

Outer Dia Gauging

We bring forth to our clients an assortment of auto outer dia checking and sorting units which are fabricated from quality raw materials and are used for checking the outer diameter of outer rings after grinding operation. These units can be customized as per the client’s specific requirements.

Customized Gauging Unit

Customized gauging unit for checking & sorting (valve seat gauging machine) are specifically designed and supplied as per the specific requirements of clients. These units are manufactured right from the concept stage which includes -

- Understanding customer requirements

- Providing a best suitable solution to such requirements

- Manufacturing such equipments and commissioning the same to customer satisfaction

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.