ATOTECH INDIA LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ATOTECH INDIA LTD.

Desmear And Metallization

Desmear and metallization

Integrated wet chemical solutions for all key market segments including IC substrates, HDI/MLB and Flex/Flex-Rigid

Quick facts

Global market leader for horizontal high end HDI manufacturing

Worldwide market reference for desmear processes in all market segments

Over 100 vertical and 230 horizontal lines are running in mass production with our electroless copper processes

Applications

Desmear

Horizontal electroless copper

Vertical electroless copper

Direct plating

Metallization of glass substrates

Panel And Pattern Plating

Panel and pattern plating

Complete solutions for all aspects of package substrate and HDI production

Quick facts

Electrolytic plating for the highest requirements in reliability and productivity

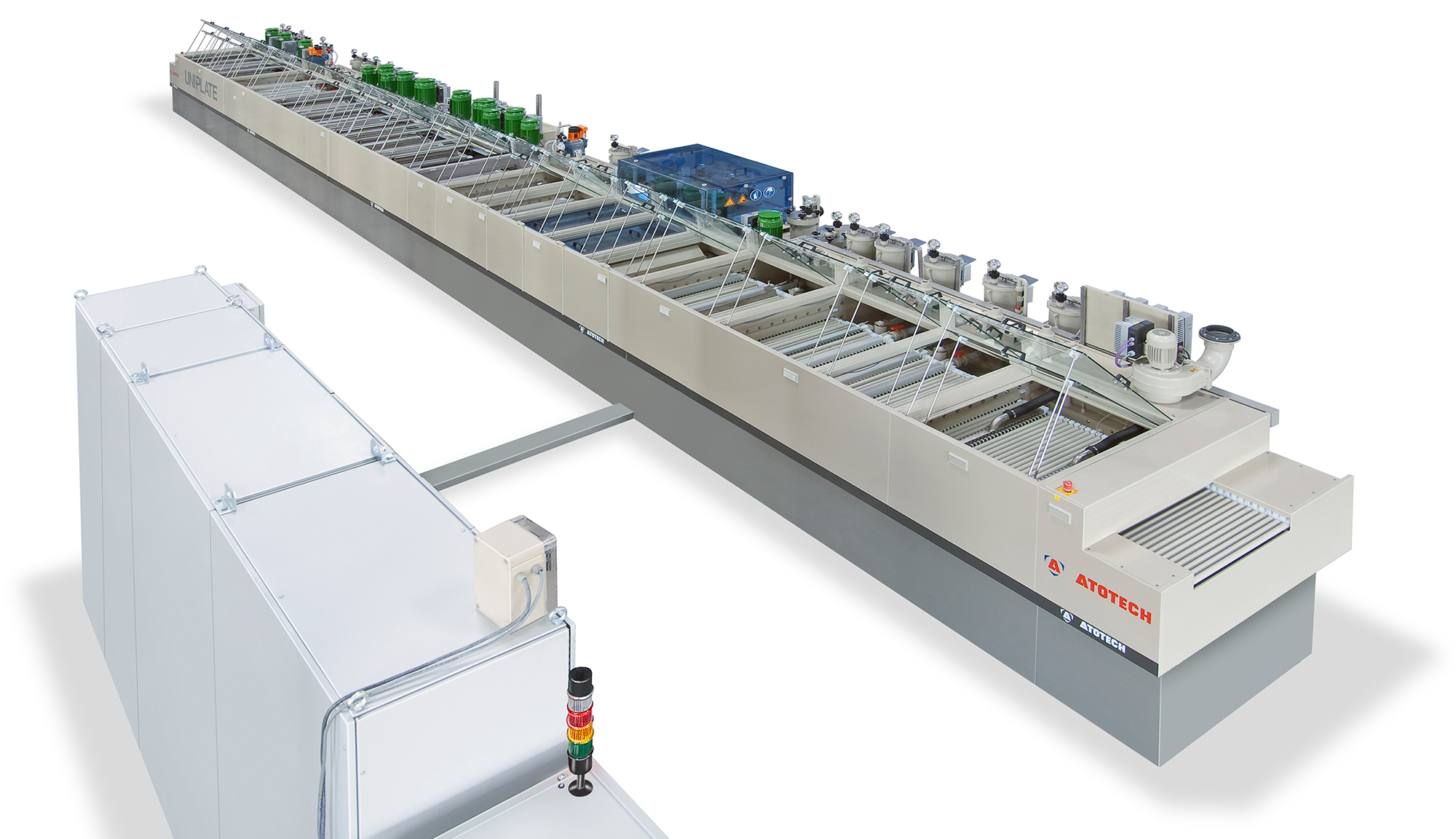

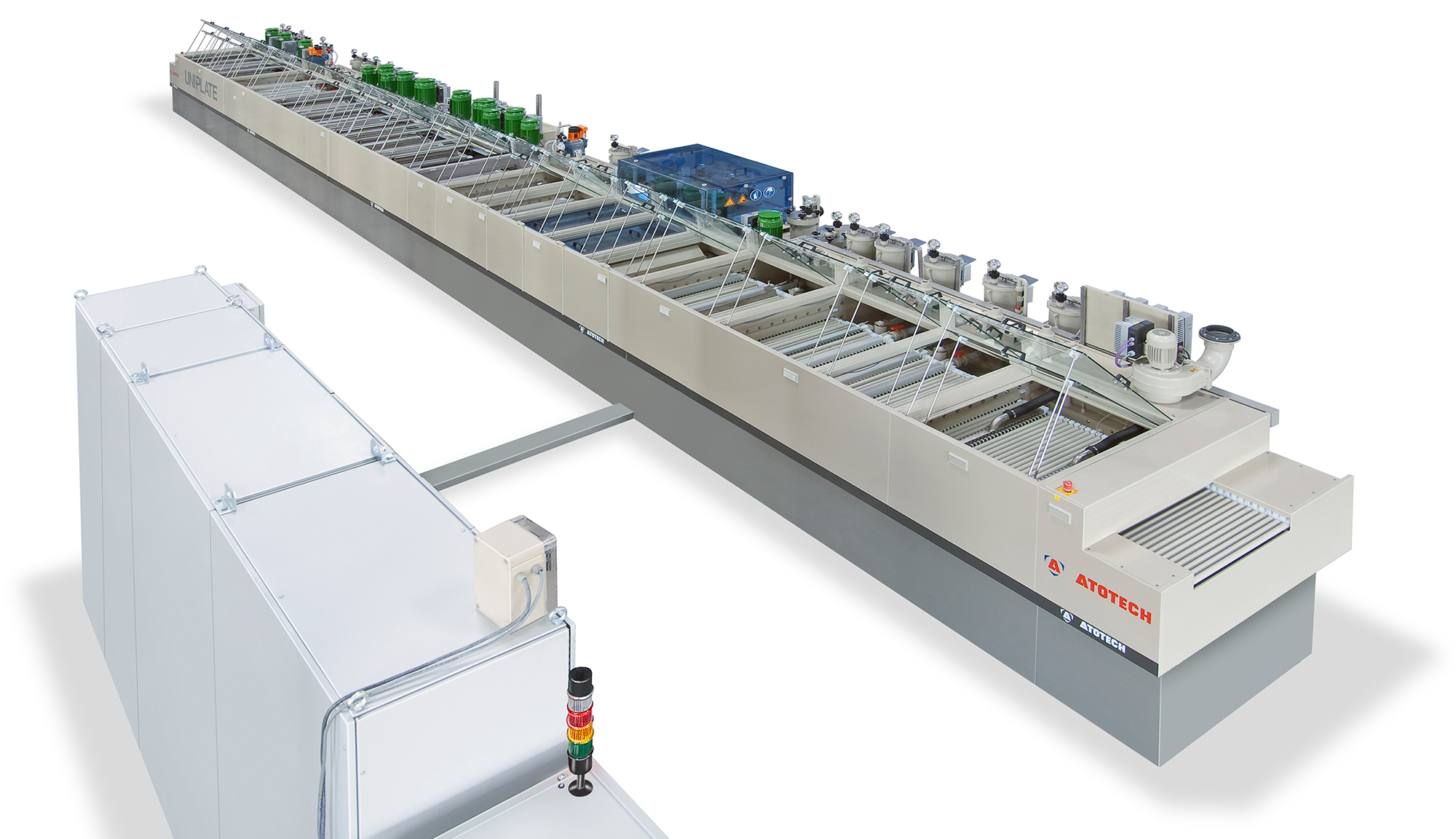

Solutions for various equipment types: Uniplate® IP2, vertical conveyorised lines, conventional hoist type

Market leading Uniplate® IP2 equipment for horizontal conveyorized production

Applications

Conformal plating

BMV filling

TH filling

Pretreatment

Metal resist, electrolytic final finishes

Final Finishing

Final finishing

Coping with the harsh environment of multiple Pb-free soldering

with a complete line of final finishes

Quick facts

Highest global market share for final finishing

Complete portfolio of final finishes

Production proven lead free processing

OEM relevant development

Applications

ENIG

ENEPIG

EP/EPAG

Immersion Tin

Bonding Enhancement

Multibond®: This Black Oxide process can be operated over a wide range of temperatures and dwell times to produce a variety of bonding properties, depending on the specific applications.

BondFilm®: Atotech’s simple and economic oxide alternative process for improved inner layer bonding. With over 400 lines and installations worldwide Atotech leads this market segment globally and contributes to the success of many key PCB manufacturers.

Secure HFz: A non-etching adhesion promoter that achieves better or comparable performance to existing etch-based enhancement processes that specifically targets IC-Substrates and high frequency applications. Secure HFz ensures enhanced bonding between copper layers and the dielectric materials used in multilayer and chip carrier manufacture. This results in excellent peel strength while also providing resistance against chemical attack.

Booster Mr

Enabling technology for direct metal deposition on molding resin: Booster® MR is a unique wet-chemical adhesion enhancement process for primer-less metal plating directly on molding resins. Direct plating on molding resin enables applications for conformal electromagnetic interference (EMI) shielding and “direct circuit formation” on molding resins, such as for FO WLP (FO PoP, FO SiP). The Booster® MR process can handle singulated and strip based products, using tape carriers to prevent the I/O side from being attacked by the plating solutions.

Plating Tool Multiplate

MultiPlate®: Atotech’s first semiconductor plating tool addresses future industry requirements such as cost effectivity and superior process performance for manufacturing of electrochemical packaging solutions. MultiPlate® is designed for single and double sided plating, through hole filling and high speed pillar plating. The tool is compatible with both wafer and panel size substrates (silicon, glass, etc.) and can be customized according to the individual production requirements.

Permanganate Desmear

Equipment highlights:

High quality stainless steel sweller and permanganate modules ensure maximum process stability and low maintenance

Integrated stainless steel filtration system for sweller and permanganate

Designed to save resources – Chemical regeneration system for continuous production at stable process parameters (Oxamat® for permanganate regeneration) and sophisticated rinse concept

Strong process performance with flood bar technology

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.