ASHU ENGINEERING COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ASHU ENGINEERING COMPANY

Twin Drum Press

Application

A need for good quality waste papers has become increasingly important for the pulp and paper industry. Under such circumstances. We have concentrated all sorts of efforts to develop? waste paper treating machineries to meet contemporary needs. We found the kneading applied to the stock while processing produces a good result in terms of de-inking, and that the dewatering prior to kneading is an important point for de-inking, Machine developed for this purpose is applicable to any type of waste paper stock as well as a virgin pulp. We are, with an original state of the technology and know how as well as practical experiences in the pulp and paper stock preparation machineries, always at your disposal for the request to improve your stock preparation system.

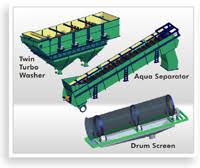

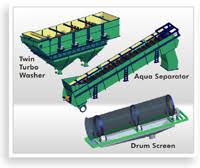

Wet Washing System

Application

The Wet Washing System is intended to wash raw material like wheat/rice straw that are high in silica and chlorides. The procedure recuperates the water utilized as a part of the washing process and render fiber with the right consistency into the pulping framework.

Equipments

Twin Turbo Washer

Aqua Separator

Screw Press

Drum Screen

Advantages

Upgrades the fibre quality for pulping

Disposes of Pith, Nodes & Fines,

Dissolves Chlorides & Soluble contraries

Removes adherent Silica

Reduces Cooking & Bleaching Chemicals

Enhances run capacity of paper machine

Results in uniform Pulp

D Type Hydra Pulper

Application

D Pulper design to reduce the dwelling time and increases the strength of the pulp. It is used to process fibrous materials (such as recycled paper) into usable slurry for manufacturing processes. They are used primarily in the pulp and paper manufacturing industry. Suitable for furnish of Virgin Pulp, Mix Waste, Broke, Box Board Cutting, Kraft Cutting Etc.

Features

Continues operation

Operating consistency 4-6%

Low in power consumption

Help to removes plastic

Rotor design helps to handling different type of furnish

Simple operation

Inexpensive and compact

Higher speed capabilities

Easy to maintenance

Low initial costs, fast payback

Break up the bales in small pieces

Remove unwanted contraries such as wire, plastic, paper clips, staples through Ragger

G Decker Thickner

Application

The G TYPE THICKENER design produce for (30% approx.) more efficiency and productivity with higher performance without the wooden bar

Thickener operates decker or rotary filter machines to remove water from pulp stock and reduce stock to specified consistency for bleaching or beating: Turns valves to regulate flow of pulp stock into machine and adjusts controls to regulate speed of cylindrical screen in vat. Turns valve to adjust suction in cylinder to deposit pulp on screen at specified rate and remove white water through meshes of screen.

Ni Agitator

Application

The agitator is a three (3) vane side-entry agitator specially designed for paper stock,

It is applicable to all chests in stock preparation such as cylindrical or rectangular and all kind of the chest, storage tanks, towers etc.

The Agitators play a critical role in the stock preparation process for mixing the pulp and give the uniform quality of pulp

Agitator shaft made of steel supported by heavy duty bearing housing

Features

Uniform and efficient dilution

Compact design

Highly effective

Motor mounting system

Maintaining homogeneity and uniform quality of pulp

Medium Consistency Screen

Application

The medium consistency screen works in 2 to 4% consistency.

Features

Proficient separation of contaminants.

Basket-hole or slotted type.

Exceptional improvement in screening efficiency.

Low power consumption.

Enhance quality of paper.

Dependable paper machine operation.

Excellent manufacturing fitness.

Step Rotor

Suitable for operation with large flat shaped contaminants.

Edges hard faced

Adjustable speed to suit wide variety of requirement.

Special design features avoid string formation.

Computerized dynamically balanced rotor.

High Density Cleaner

Application

Ashu's supplies pulp cleaners for the pulp and paper industry to remove dense contaminants from paper pulp. These units fall into two basic categories: continuous rejects cleaners that are usually installed in multiple stages to remove fine sand from paper pulp and intermittent rejects cleaners that are designed to collect larger reject material and to discharge it intermittently to minimize fibre loss.

Features

Efficient removal of bad contaminants like sand, chips, pins, glass etc. from the pulp stock

Working consistency 2.5 3.5%

Easy installation

Compact design

Illuminated sight glass for visual inspection

Vibrating Screen

Application

These mechanical vibrating screens have been used for decades in the pulp and paper industry from screening stock in low consistency up to 1.5%. The stock flows through the feeder against the vibrating screen plate. The accepted fibre passes through the perforation of the screen plate, while the knits and impurities remaining on it carried to the reject outlet. The good fibres, which adhere to the rejects, are washed off by a twin water curtain so that the rejects are carried to the reject outlet by the vibratory elliptical motion of the screen through.

Turbo Separator

Application

The Turbo Separator uses centrifugal forces to stratify the stock into three regions, heavy rejects, light rejects and acceptable materials (accepts/fibres). Heavy rejects are forced against the outside wall, light rejects remain in the centre, and acceptable materials (accepts/fibres) migrate to the region in between. Heavy rejects exit the Turbo Separator via a tangential pipe at the top of the machine. This enables them to exit at high pressure. No pump is needed to move them to the High/medium/low Density Cleaner (Secondary fibre recovery device). Light rejects exit.

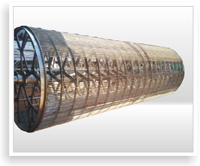

Trommel Screen

Application

The Trommel is a drum washer designed to further separate the remaining fibers from the discharged contaminants from the de-trasher in the Pulper. The Trommel is a horizontal drum washer specially designed to overcome the, problems inherent with other designs, like mechanical problems on drive, noisy operation. Cost of maintenance and difficult installation.

Centri Cleaner

Application

Centri cleaners is designed and manufactured from high quality SS 304 & 316 sheets for highly efficient removal of light particles such as sand, bark, dirt, specks and shives, The design and finishing has proved a high cleaning efficiency. The Centricleaner is also polished from inside for high cleaning efficiency and outside for better finish and good look, The quality and workmanship pays off in unbeatable long term performance and life. The Centricleaner is provided in different capacities as per the choice and need of the users. The normal capacity available is from 400 LPM to 1500 LPM.

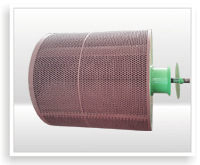

Cylinder Mould

Application

The principle of the cylinder mould is to provide the forming surface through which water drains to leave the fibers matted in a sheet. The cylinder is designed to allow drainage uniformly across its width with no turbulence to disturb the fibers during formation.

Outstanding features include:

High drawing efficiency

Near perfect concentricity

Maximum open area

Ease of cleaning

Minimum deflection due to a design which emphasizes stiffness and rigidity

Lye Mixer

Application

The unique design for lye mixture help to proper mixing of the material (water, chemical & lye) and dump in the digester system then the Packer also help to pack the maximum material in the digester system. The design of lye mixer and its track is vary according to suitability of space and the requirement of the customer.

Hi Consistency Pulper

Application

The Hi-con. Pulper designed for slushing the contaminated, unsorted or sorted waste paper such as note books NCC, SACK KRAFT, OCC, NDLKC, INDIAN CUTTING etc. the pulperoperates a special rotor, the rotor made out from Cast steel (SS316,304 grade)with coated edge. Its operates from 14 to 15 % consistency

Features

Removed the negligible fiber loss

Easily circulation of the stock

Uniform slushing

Low power consumption

Excellent in lessening of ink pigments etc from the pulp.

Single Disk Refiner

Application

Refiner can be equipped with direct dilution water feeding for processing dry raw material for fiber production to enhance the fiber quality and prolong the lifetime of the refiner plates.

Features

Improve fiber quality

Compact design

Highly effective

Maintaining homogeneity and uniform quality of pulp

Medium Density Cleaner

Application

Ashu’s supplies pulp cleaners for the pulp and paper industry to remove dense contaminants from paper pulp. These units fall into two basic categories: continuous rejects cleaners that are usually installed in multiple stages to remove fine sand from paper pulp and intermittent rejects cleaners that are designed to collect larger reject material and to discharge it intermittently to minimize fibre loss.

Dryer Cylinder

Application

After passing the paper from whole Press Section, Paper remains still wet hence it requires to eliminate remaining water which can only be completed through the application of heat. This is carried out by Paper Machine Drying section consist of a series of steam heated cylinders varying in diameter. These Dryers they fabricate from Mild Steel which has top quality and high efficiency with hydrolic testing.

Rotors

Description / Specification of Rotors

We are involved in offering a wide range of Rotors to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Rotors. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Perforated Screen

Description / Specification of Perforated Screen

We are involved in offering a wide range of Perforated Screen to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Perforated Screen. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Vaccum Box

Description / Specification of Vaccum Box

We are involved in offering a wide range of Vaccum Box to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Vaccum Box. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Core Pipe Shaft

Description / Specification of Core Pipe Shaft

We are involved in offering a wide range of Core Pipe Shaft to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Core Pipe Shaft. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Straw Cutter

Description / Specification of Straw Cutter

We are involved in offering a wide range of Straw Cutter to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Straw Cutter. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Sand Filter Tank

Description / Specification of Sand Filter Tank

We are involved in offering a wide range of Sand Filter Tank to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Sand Filter Tank. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

62364.jpg)