ARVIND LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ARVIND LTD.

Cover All Garments

Description / Specification of Cover All Garments

We are involved in offering a wide range of Cover All Garments to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Cover All Garments. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Multi Layers Suits

Three layered aluminized kevlar heat protective suit.

Three layered heat protective suit made from kevlar based aluminized material. The suit consists of suit, hood, glove and boot.

Material of construction:

Outer layer:

- The outer layer is made from aluminized kevlar material

- The fabric has a total weight of 400gsm (+-5%)

- The fabric is tested and certified to en11612 a b2 c3 & e3.

- The fabric offers excellent and easy wearing, radiant and convective heat protection.

Second layer:

- The second layer (moisture barrier) is made from neoprene coated fiber glass material.

Inner most layer:

- The inner most layer is made from flame retardant fabric

- The fabric has a total weight of 340 g/m2 (+/- 5g/m2).

Uniform Garment

Arvind Holds exclusive license for manufacturing PROBAN and NOMEX fabrics and Garments in India, Arvind Pro1 Range of fire retardant fabrics and Garments can come with high visibility –EN471 certification and antistatic properties and a verity of other functional finishes.

Each Product at Arvind development centre goes through a complete cycle of pattern engineering methodology and risk analysis, fit reviews and critical path. High Skilled technical team has the capabilities of devolving concepts, through to the final Product. Customer can have total confidence that their specification and individual requirements will be met.

Arvind has 5s Factory (Visual Control):-Lean Cut to Box Layouts:

Each line functions as mini factory. KANBAN based tracking system assures 100% accountability. Cut to box function on pull system resulting in minimum inventory at all process.

Roving QA system working on SPC result in stringent in line quality control. All operations are set as per operation bulletin based on GSD.

Filtration Fabrics

At Advance Materials we produce fabrics with the latest technology to offer an advantage our customer during filtration. We are committed to deliver fabrics with consistent air permeability and pore size throughout the length & width. This helps in consistent cake build-up and retention of desired particles.

These Fabrics are used in various process filtration applications such as ferrous, non-ferrous metals, mineral processing, general chemical industry, dyes and intermediates, dewatering, pharmaceuticals, fertilizers, food etc.

These fabrics are made available in 100 % Monofilaments, Multifilament, spun and also with various combinations. Looking into various process and product requirements we can provide joint less width till 3.30 meters. To cater each and every need of industry we produce fabrics with pore size rating of 1 micron to 2000 microns.

Our special Monofilament Fabrics are available with a polymer chemistry which offer easy cake discharge and ability to get cleaned quickly. These fabrics also present excellent mechanical strength and dimensional stability.

We produce range of food grade fabrics which comply US FDA and EC 10/2011 standards.

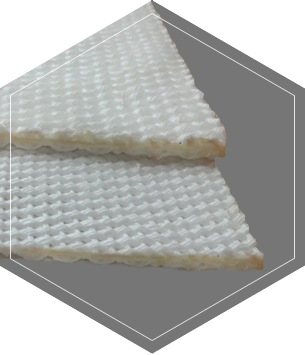

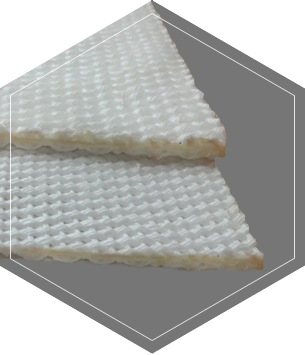

Nonwoven Felts

Arvind OG Nonwoven Pvt. Ltd. (AOG) is a joint venture between Arvind Ltd. (India) and OG Corporation (Japan) having manufacturing facilities near Ahmedabad, Gujarat. AOG manufactures high quality Nonwoven fabrics using Needle-punch technology for Bag-house Filteration, Artificial leather, Geo-textiles, Electrical insulation and Automotive headliner applications.

AOG has installed custom-built machines specifically designed to meet international quality standards and capable of handling various fibers such as M-Aramid, Homopolymer Acrylic, Poly-phenelyene Sulfone (PPS) and Polyimide, Polypropylene and Polyester.

Industrial Belting Fabric

Arvind Advanced Materials offers range of Industrial belting fabrics for Mining, Infrastructure, Textiles, Pharmaceuticals, Power transmission and Food industry. Advanced Materials is an ISO 9001-2008 approved manufacturing facility.

We offer following fabrics for Industrial Belting applications:

- Monofilaments (Polyester, PPS, Nomex)

- Multifilament (Polyester, Nylon 6, Nylon 66,P-aramid)

- Spun Polyester

- Cotton Canvas

- Polyester-Cotton blends

- Fiberglass

These fabrics are made on state of the art twisting, warping and fabric weaving machines.

Fabrics are available in widths up to 3600 mm ranging from 100 gms/m2 to 3500 gms/m2 and upto 2000 meters of roll length, catering to most industrial belting applications.

Meshes

Arvind Advanced Materials is engaged into manufacturing of High Performance Industrial Monofilament Mesh Fabrics and Drying belts. We offer Monofilament Mesh fabrics till 3.20 meters width for various drying and conveying applications. These meshes are available in PET, PA,PP and other special Polymers.

We also have fabrics available which comply US FDA standards for food and pharmacy applications.

Coating Substrate

Arvind Advanced Materials offers range of coating substrate fabrics for various outdoor/indoor applications. Advanced Materials is an ISO 9001-2008 manufacturing facility.

The coated substrate fabrics are used in various applications such as tents, outdoor architectural structures, bio-gas domes, automotives, Upholstery, etc.

At Advanced materials we produce fabric with the latest technology to offer our customer an advantage during coating process. We are committed to offer fabric which are free of distortion and filamentation, have uniform weight and width and very low shrinkage.

Our fabrics are available upto width of 3.50 meters and roll length upto 1000 linear meters. These fabrics are made available in 100% Monofilaments, Multifilament, Spun and also with various combinations.

High Temperature Textiles

At Advance Materials Division we produce high temperature resistant fabric that can withstand high temperature and can cater wide range of industrial requirements.

The fabrics that are used for high temperature Textile are:

- Glass cloth

- Silica cloth

- Ceramic cloth

End User Industries:

- Steel

- Power

- Automotive

Automotive Textile Fabric

Arvind Ltd. (Advanced Materials Division) offers fabrics for Automotive Seating Systems in following technologies:

- Woven (Dobby & Jacquard)

- Circular Knit

Ours is a fully integrated fabric making plant with in-house facility for Yarn Dyeing, Weaving (Jacquard and Dobby), Circular Knitting, Fabric Dyeing, Finishing, Lamination and Embossing.

we are suppling to leading automotive brands in india.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.