AMETECH SYSTEMS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AMETECH SYSTEMS P.LTD.

Electronic Weighbridge

The platform consists of I-beams for trouble free operations year after year. Depending on the space available , both pit type and pit less designs are available. The digital load cells are pre-calibrated at full load capacity to prevent manual labour required to lift and place standard weights for cornering and calibration. This allows for an installation time of less than 8 hours and helps shorten project lead time.

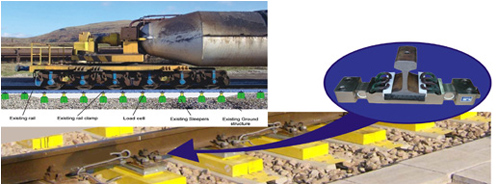

Awc Dynamic (In Motion) Axle Weighbridge

Axle Weighbridge 53010.jpg)

Application

The AWC Dynamic (In-Motion) Axle Weighbridge is designed to be an economical and convenient solution for measuring the weight of moving trucks.

The AWC JUMBO Dynamic (In-Motion) Axle Weighbridge is a system consisting of individual weighing platforms which measure the load on each wheel of a dumper truck dynamically or statically. Its modular design enables any possible truck axle configuration or model of mining dumper truck.

A large external LED display is available for quick and easy viewing of the weights. A traffic light can be used with the large display to tell the driver when to move on and off the weighbridge.

Onboard Weighing For Front Loaders

On Board Weighing Systems used in forklifts and front end loaders are usually hydraulic based using a pressure transducer fitted into the hydraulic lines to provide a pressure reading which is translated into a weight reading by a digital weight indicator The pressure in the lifting cylinder is tapped at a location where the bucket will be parallel to the ground to achieve repeatability. The low level signal from the pressure sensor is amplified and filtered by the high precision monolithic A/D converter and converted into digital format. With the aid of pressure and position sensors, the electronics evaluates complex dynamic weighing calculations to easy to read data shown on a large TFT colour display screen, all in real time. The dynamic weighing feature allows for weight measurements to be carried out even whilst the vehicle is in motion, preventing the need for lifting operation to be momentarily stopped The digitized data is further processed and stored according to the customer need and application.

Ladle Transfer Car Weighing System

The Ladle Transfer Car Weighing System weighs ladles, pots and scrap buckets. The systems are designed to fit existing or new cars with weigh modules containing DWB double – ended shear beam load cells . The load cells are installed between the base structure and the weighbridge, without need for modifications of the ladle supporting geometry. The load cells and teflon cables are designed to with stand temperatures of over 250ºc.

Specifications

Floating load cell bearing assemblies.

Double – ended shear beam load cells .

Digital weight instrument .

250ºC load cells.

Static Ladle Car Weighing System

HotMetalRailWeigh is a static weighing system designed for the weighing of hot ladle cars. Precision QS-G load cells made in the form of the rail determine the weight of the ladle car. This is done by positioning the precision load cells beneath each of the wheels of the ladle car. The load cells and teflon cables are designed to withstand temperatures of over 250°C. The weight values are acquired and processed with the use of weighing electronics and customized PC systems.

Benefits

Static weighing of hot ladle cars.

Pitless and gap free design.

Simple installation – no frame needed.

Suitable for very harsh environments

Precise determination of hot metal output.

Overhead Crane Weighing System

The overeahead crane is designed to weigh the ladle at the upper sheave assembly to measure amount of liquid metal while pouring into a furnace. This will improve the yield as well as the end point control.High temperature load cells and rope weight compensation facility gives accurate results.

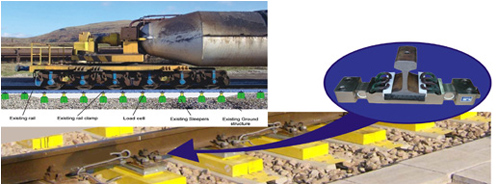

Torpedo Weighing Rail Scale

Application The AMSTEL Torpedo Weighing Rail Scale is a pit less state of the art static weighing scale for hot torpedo cars. High – precision , high–temperature load cells are installed between the existing rail clamps and the existing wooden or concrete sleepers. They reliably transmit all vertical forces applied by the torpedo car wheels , with a high degree of accuracy and repeatability. The weighing system is installed without a foundation and can be installed without additional effort during a normal track maintenance period.

Ladle Weighbridge

The Ladle Weighbridge is designed to weigh hot ladles and slag pots. The weighbridge utilizes DWB series double shear beam high temperature load cells and cable that can withstand temperatures of over 250°C . These load cells have self- aligning bearing assemblies and flexure plate checking system.

Specifications

Digital Weighbridge

Double-ended shear beam load cells .

High temperature load cells and cable

Floating load cell bearing assemblies

Flexure plate checking system

Self aligning system

Digital indicator with printer, computer and wireless CellModem interface

Belt Weigher

A BELT WEIGHER is a piece of industrial equipment used to gauge the mass or flow rate of material travailing over a troughed (cupped) conveyor belt of any length which is able to adequately contain the material being weighed.

Commonly incorporated into conveyor belt systems, belt weighers are used in a wide range of industries to report instantaneous flow rate and totalised mass feed rate of powders and bulk solid materials. This data is commonly used for stock control, process control and in bulk material handling processes.

Weigh Feeder

AMSTEL offers Weigh Feeders to feed bulk solids continuously to the process In a Weigh Feeder, product is fed as a continuous band onto a conveyor belt, through an inlet slide gate or automatic pre-feeder. Load cells under the belt continuously measures the weight of the product over a defined length of belt. The Weigh Feeders are suitable for installation in industrialized environment with light & heavy duty conditions respectively. They are specifically designed to provide dependable service with minimum maintenance and care. Heavy duty, Long life components are selected to assure a stable and distortion free compact assembly capable of withstanding tough industrial conditions.

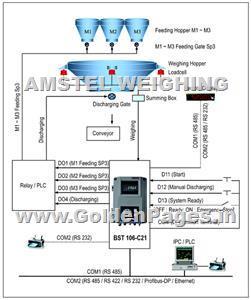

Automated Batching System

Application

The control system allows blending of multiple products into a single weigh bin.The achievable weighing accuracy is commensurate with that of a static weighing system. Up to ten components may be automatically batched in a preset sequence, according to a programmed recipe. Semi-automatic and manual modes of operation may also be selected. In-flight compensation, agitation and settling time is selectable per product. The stand-alone batching system can store up to 10 recipes, each with up to 10 components. When under computer control (SCADA, PLC etc) the number of recipes is unlimited.

Main Features Of Weighing Controller

Data calibration and load calibration facility.

Support industry configuration software.

Weighing reports can be printed.

EMC design with high anti-jamming capability, suitable for industrial environment.

Menu & shortcut mode operation with key tone.

ARM CPU system with high arithmetic speed.

24-bit High-precision and high-speed sigma-delta A/D conversion module with 130,000 internal code [AD value] used and 200Hz sampling frequency.

Special filtering algorithm for ensuring weighing stability and accuracy when there is strong vibration on the load receptor, and rapid response capability with changes in weight signal.

Auto-locking, key-locking, key-unlocking, digital setting & calibration and I/O Testing functions

1 optional and definable analog signal output ( 4-20mA )

3 normally open switch inputs [DI] and 4 normally open relay or transistor switch outputs [DO].

2 optional communication ports for linking to PC/PLC, remote display or operation terminal, serial printer, wireless module, etc.

With the multitasking mode, the weighing & control process will not be interrupted by parameter setting and the other operations.

Amsteltop Fill Pail And Drum Filler

AMSTEL Top Fill Pail Filler provide a reliable and quick way to fill non-foamy products. The model T-5 is designed to provide accurate liquid filling of upto 50 kg pails.

Standard Features

User friendly menu driven system

Recipe programming & saving of all fill set points

Slow-fast-slow fill mode programming

Automatic preact calculation

Resume capability to continue filling aborted fill cycles

“No pail no fill” feature to prevent product spillage

Net weight over/under fill monitoring

Weight indicator control, zero, tare, gross/net

*Two ball valve system for slow-fast-slow fill modes

*Hand operated lever for fill start/stop operation

Standard construction

304 stainless steel structural construction

316 stainless steel wetted parts (lance & pipe)

Powder coated carbon steel control NEMA-4 enclosures

Two piece 316 stainless steel ball valves Teflon seals & seats

Carbon steel low profile scale case

Raised platform

Sealed load cells

1 part in 5,000 resolution

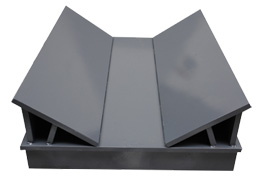

Weighpad

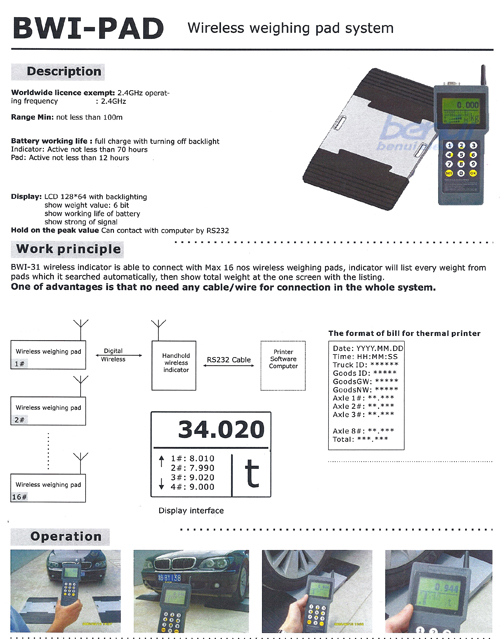

Description

Worldwide licence exempt : 2.4GHz

Operating frequency : 2.4GHz.

Range Min : not less than 100m.

Battery working life: full charge with turning off backlight .

Indicator Active not less than 70 hours.

Pad ; Active not less than 12 hours.

Indicator

The microcontroller based electronics indicator is extremely reliable and user friendly . The built –in RS232C communications interface allows easy connection to a computer and printer , and enables an effective computerized weight management systems .

Display : LCD 128 x 64 with backlighting show weight value : 6 bit , show working life of battery show strong of signal .

Hold on the peak value Can contact with computer by RS232. Work principle

BWI – 31 wireless indicator is able to connect with Max 16 nos. wireless weighing pads , indicator will list every weight from pads which it searched automatically , then show total weight at the one screen with the listing .

One of advantages is that no need any cable / wire for connection in the whole system.

High Temperature Load Cell

Application:

The high temperature load cells have a compensated working temperature range of +200ºC and a limit temperature range of +250ºC. They are manufactured using special strain gauges, adhesive ,wiring and teflon cable to withstand the high temperature. This makes then suitable for weighing systems for tundish , ladle transfer cars , ladle turrets , ladle cranes , foundry cranes etc and other applications that are subject to intense heat.

Load cells can also be offered having the same body style and capacities as ABB and Schenck load cells replacing capacities from 10MT to 160MT.

Wireless Load Cell

Wireless load cell

Description

Operating Frequency : 433 MHz operating frequency

Minimum Range : Not less than 200M.

Protection Class : IP67

Combined Error : ± 0.03% F.S.

Operating Temperature Range : -30 + 70

Safe overload Limit : 120% F.S.

Ultimate Overload Limit : 200% F.S.

Construction : Alloy Steel

Cellmodem

The CELLMODEM is an accessory of the REM-LINK YIELD TOOL. It provides a wireless interface from a REM – LINK YIELD TOOL to any serial device . Support is provided for computers, large displays, printers PLCs and virtually any serial connected device . It is a wireless module used for wireless data transmission with a small size , weight and power consumption . Single chip radio frequency integrated circuit and single chip MCU are used for lessening peripheral circuits, high reliability and low failure rate. .

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

Axle Weighbridge 53010.jpg)