Products & Services

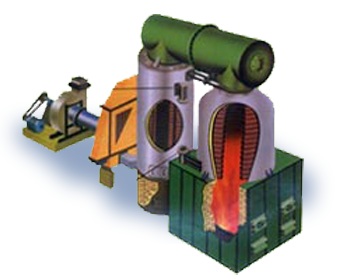

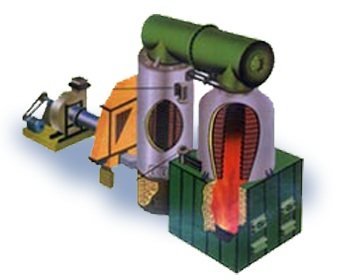

Horizontal Thermic Fluid Heater

This system is forced circulation fully automatic thermic fluid heater where thermic fluid is circulated in a closed loop through heater and user equipment circuit where the heat is dissipated to process. The same thermic fluid is re-circulated through heater for heating. The thermic fluid heater gives high temperature upto 300 oC using thermic fluid oil at near atmospheric pressure as compared to steam heating which requires 85 Kg/Cm2 pressure

Horizontal Thermic Fluid Heaters

This system is forced circulation fully automatic thermic fluid heater where thermic fluid is circulated in a closed loop through heater and user equipment circuit where the heat is dissipated to process. The same thermic fluid is re-circulated through heater for heating. The thermic fluid heater gives high temperature upto 300 oC using thermic fluid oil at near atmospheric pressure as compared to steam heating which requires 85 Kg/Cm2 pressure

65031.jpg)