Products & Services

Fluid Bed Granulator Cum Coater

ACMEFIL Fluid Bed processing includes Drying as well as granulation, agglomeration and coating of particulate materials.

It is designed to uniform drying of the material at low temperature and is ideal for a wide range of both heat sensitive and non-heat sensitive prodcts for low moist powder.

Vibratory Fluid Bed Dryer Continuous Type

Description / Specification of Vibratory Fluid Bed Dryer Continuous Type

We are involved in offering a wide range of Vibratory Fluid Bed Dryer Continuous Type to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Vibratory Fluid Bed Dryer Continuous Type. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Ultra Filtration System And Membrane System

Membrane technology is the latest and most advanced separation technologies available and used today. The main advantage of membrane technology is, it brings separation without the use of expensive chemicals, minimal unavailable power, no thermal energy requirement and uses the least floor space for said application and proceeds in well defined process conditions

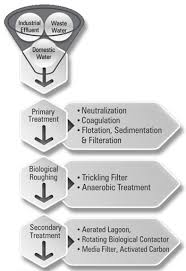

Zero Effluent Discharge System

Description / Specification of Zero Effluent Discharge System

We are involved in offering a wide range of Zero Effluent Discharge System to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Zero Effluent Discharge System. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design