ACME AIR EQUIPMENTS CO.P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ACME AIR EQUIPMENTS CO.P.LTD.

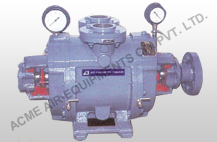

Win Lobe Roots Blower Positive Displacement Blowers

Acme Air Equipments Company Pvt. Ltd. is an ISO 9001-2015 company. We are into full fledged manufacturing of a wide range of Twin Lobe Rotary Compressors / Exhausters. These are also known as Twin Lobe Roots Blower / Vacuum Pump, used in various systems and plants like Sewage Treatment Plants. These are High volume-low pressure positive displacement (PD Type) Roots Blowers. They operate on differential pressure and constant volume characteristics.

We manufacture a wide range grouped under air cooled or water cooled design which covers capacities from 10 M³/Hr to 14000 M³/Hr.

We manufacture these machines Twin Lobe Rotary Compressors, positive displacement blowers in our state-of-the-art modern facility equipped with CNC machines, CAD-CAM software and efficient production control system.

Mechanical Vacuum Boosters (Booster Compressor)

65624.jpg)

Acme Air Equipments Company Pvt. Ltd. is an ISO 9001-2015 Company. We design and manufacture premium quality Mechanical Vacuum Boosters as well as complete Vacuum Booster System in our State-of-the-art modern manufacturing facility. This is an ideal vacuum systems for re-used oil distillation.

The design and construction of vacuum booster compressor involves two counter rotating impellers with a special contour. These rotate with a very finite and sharp clearance and without any physical contact. Variance in design offers Twin or Tri lobe Booster in air cooled or water cooled execution. The Boosters are designed to handle vapors and gases at lower specific power consumption. They offer precise and constant volume displacement at rated condition.

Tri Lobe Roots Blower (Rotary Lobe Compressor) And Exhausters

And Exhausters 65625.jpg)

This is an advanced design of Tri Lobe Roots Blower which is also called as rotary lobe compressor and rotary piston blower. Basic concepts present in a Twin Lobe Rotary Compressor are modified. The configuration of Rotor is changed to Tri Lobe. This profile enables the rotor pair to entrap and sweep the volume of air/gas 6 times in a revolution. Effectively it delivers higher capacity with smooth flow. The rugged design of Tri Lobe Rotary Compressor with higher rigidity makes it possible to run these machines at higher speed with acceptable vibration level. The roots compressor range covers 5 models from 1000 M3/Hr to 18000 M3/Hr. These are air cooled models.

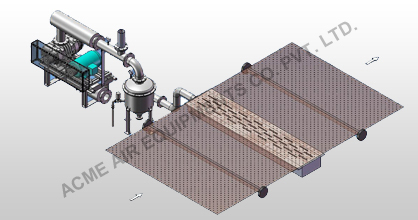

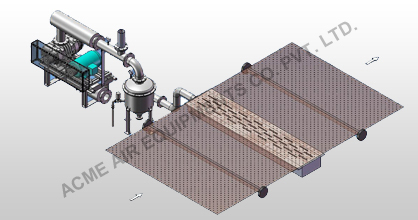

Cement Conveying System Fly Ash Feeding System

Acme Air Equipments Company Pvt. Ltd. is an ISO 9001-2015company. We are premium quality equipment manufacturer and solution provider. We offer packaged system for conveying/feeding Cement/Fly Ash into silos at Batching Plant sites. These systems are synonymous with modern and efficient construction industry practices contributing to improvement in technique and efficiency.

Catalyst Loading And Unloading Systems

Acme Air Equipments Company Pvt. Ltd is ISO 9001-2015 Quality Certified manufacturer. We design and manufacture Complete and Comprehensive System for loading/unloading of Catalysts to and from reactors/reformers in Petro- Chemical, Fertilizer, Chemical, Pharmaceutical, Atomic Energy and many other industries.

Pneumatic Conveying System

Pneumatic Conveying System

Acme Air Equipments Company Pvt. Ltd. is an ISO 9001-2015 quality certified company. The company offers state-of-the-art solutions for bulk material handling which is widely employed material handling technique.

Product Description

Pneumatic Conveying System is a widely adopted means of transporting dry bulk material either by Vacuum or by Pressure of Air. Depending on the material to be conveyed, the air stream with specific velocity will carry the material to the final destination.

Dewatering System Vacuum Dewatering System

Acme Air Equipments Company Pvt. Ltd. is an ISO 9001-2015 quality certified company. It is a most trusted and quality manufacturer of Twin/Tri Lobe Roots Blower, Vacuum Dewatering System and allied systems, established in 1990.

There are numerous industrial applications which utilize large volume of water as a part of their production process. Subsequently however this excess amount of water has to be removed before finishing the end product.

This is typical to solid or semi solid material like minerals, textiles, plastic granules etc.

Dust Collection System

In many industrial situations surrounding atmosphere is laden with spillage or escape of very low density solid matter which hampers the production and causes the environmental problems which are detrimental to health. These hazardous particles need to be trapped in dust collection system (centralised vacuum cleaning system) and conveyed to a pre-determined location.

Gas Boosters (Booster Compressor)

65631.jpg)

Acme Air Equipments Company Pvt. Ltd. is an ISO 9001-2015 quality certified company. It is a most trusted and quality manufacturer of Gas Boosters (Booster Compressor), Twin/Tri Lobe Roots Blower and allied systems, established in 1990.

The natural gas is now widely used in many industries like power plants, furnaces, burners, glass manufacturing etc. to name a few. Depending on the variation in the consumption pattern by the different industries connected to the grid; fluctuations occur in the operating pressure. For consistency of quality and productivity it is necessary to maintain constant gas pressure for trouble free running of such installations. Our state-of-the-art Booster Compressor design fulfills this requirement.

Oil Sealed Vacuum Pump

Acme Air Equipments Company Pvt. Ltd.-an ISO 9001-2015 company- offers a proven, versatile and precise Oil Sealed Vacuum Pump.

This is generally most adopted type of Vacuum pump in the industry for producing pressures up to 5X10-3 mbar in single stage and 5X 10-4 mbar in two stage execution. The mechanism, which is lubricated by oil, consists of a stator and an eccentric rotor. The rotor has two vanes in diametric slots. These vanes are held apart by a spring.

Water Ring Vacuum Pump

Principle of Water Ring Vacuum Pump

The casing of the machine is cylindrical with control disc on either side. An eccentrically located impeller with curved blades rotates within the casing. The liquid (preferably ) introduced is set into rotary motion by the blades, thus forming the water ring concentric with the casing. Cells are formed between the ring and the blades of the impeller which vary in volume from maximum to minimum with each revolution. The conveying medium enters the working chamber through the opening in the lateral control discs and is compressed by the decrease in volume of the cells. It then flows together with the cooling through discharge opening in the control discs to the delivery port.

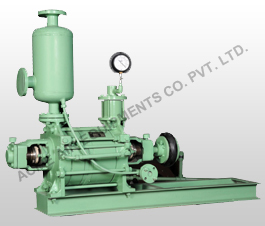

Two Stage Liquid Ring Vacuum Pump

Acme Air Equipments Company Pvt. Ltd.-an ISO 9001-2015 company- offers an efficient and user friendly Two Stage Liquid Ring Vacuum Pump.

This pump is the double of single stage vacuum pump operating in series. Thus the discharge from the first stage goes into the suction port of the second stage.

Integral two stage impellers are able to condense process vapors and recover or dispose them off. The two stage pumps have better efficiency at higher vacuum levels as compared to a single stage vacuum pump.

Liquid Ring Vacuum Pump

Acme Air Equipments Company Pvt. Ltd.- ISO 9001-2015certified liquid ring vacuum pump manufacturers offer a robust, efficient and easy to maintain pump.

AEC AV series pumps and liquid ring vacuum compressors are rotary machines in which liquid is made to act as piston. A balanced cylindrical rotor with hollow hub and a series of curved blades projecting radially, turns freely in a cylindrical casing which is large in diameter than the rotor. The blades of the rotor are enclosed at the sides thus forming a series of buckets, open at the bottom into the hollow center.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

65624.jpg)

And Exhausters 65625.jpg)