ABHISHEK PHARMA ENGINEERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ABHISHEK PHARMA ENGINEERS

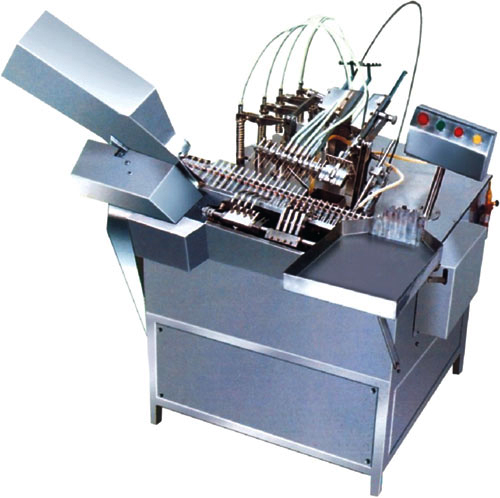

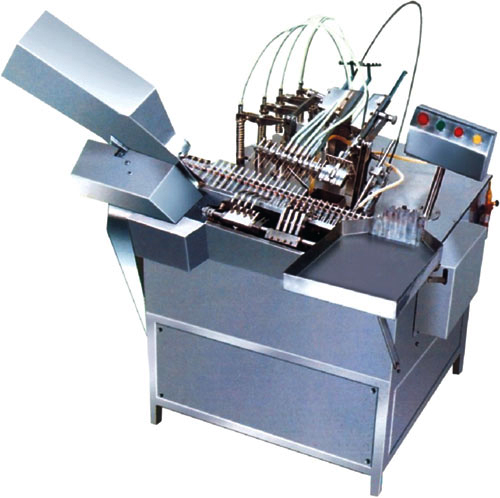

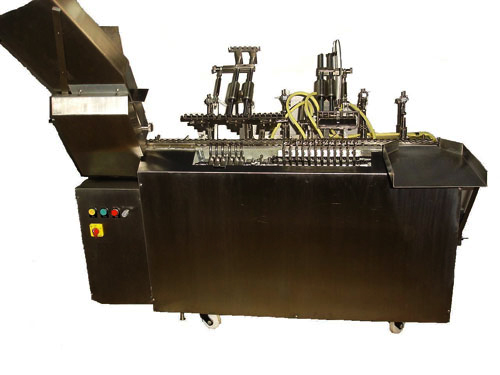

Ampoule Filling And Sealing Machine

Ampoule Filling & Sealing Machine is uses for the filling & sealing of glass ampoules. Machine is widely uses in pharmaceutical, biotech, cosmetic & chemical industry.

Features

» Compact GMP model

»Production output ranging from 30 ampoules/minute to 150 ampoules/minute

» All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

» Machine is suitable to fill 1ml to 20ml ampoules with the help of change parts

» Ampoule neck centering during gas flushing and filling operations

» Possibility of Nitrogen Gas flushing before & after filling

Technical Specification

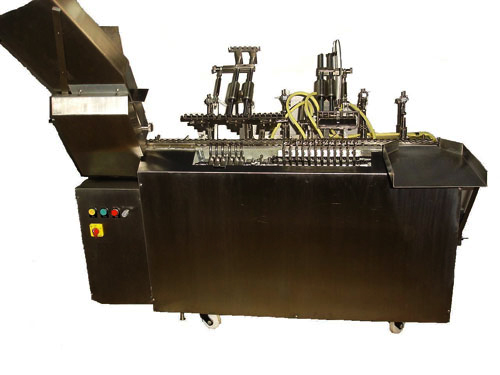

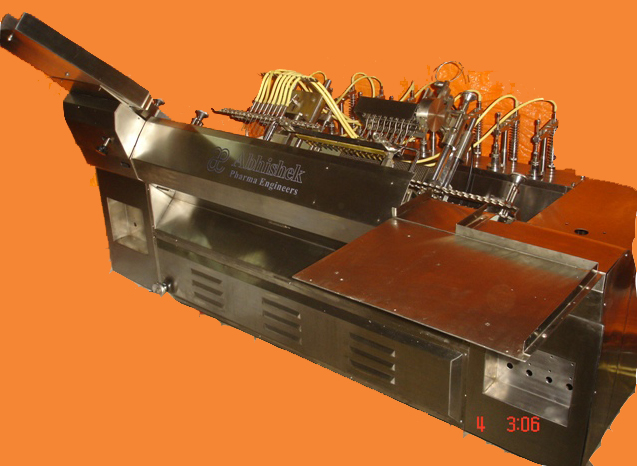

Ampoule Filler Sealer

Ampoule Filler Sealer is uses for the filling & sealing of glass ampoules. Machine is widely uses in pharmaceutical, biotech, cosmetic & chemical industry.

Features

» Compact GMP model

»Production output ranging from 30 ampoules/minute to 150 ampoules/minute

» All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

» Machine is suitable to fill 1ml to 20ml ampoules and minimum change over parts from 1ml to 20ml ampoule size

» Ampoule neck centering during gas flushing and filling operations

» Possibility of Nitrogen Gas flushing before & after filling

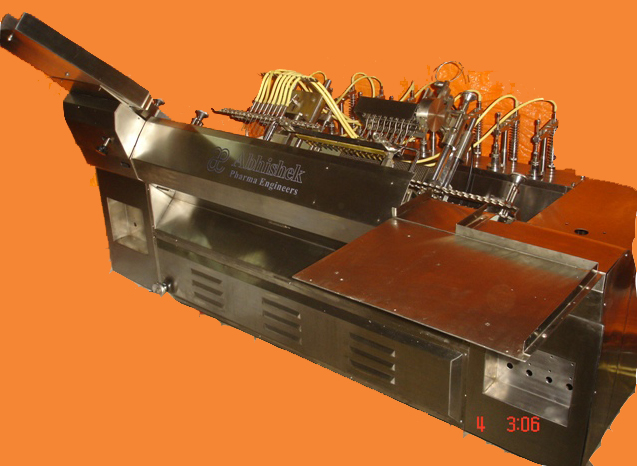

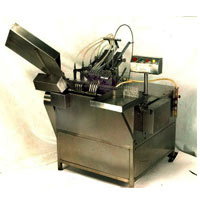

Single Head Ampoule Filling Sealing Machine

Single Head Ampoule Filling Sealing Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

Features

» Compact GMP model

»Production output ranging from 15 to 30 ampoules/minute

» All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

»Machine is suitable to fill 1ml to 20ml ampoules with the help of change parts

Two Head Ampoule Filling Sealing Machine

Two Head Ampoule Filling Sealing Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

Features

» Compact GMP model

»Production output ranging from 25 to 35 ampoules/minute

» All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

»Machine is suitable to fill 1ml to 25ml ampoules with the help of change parts

» Ampoule neck centering during gas flushing and filling operations Possibility of Nitrogen Gas flushing before & after filling

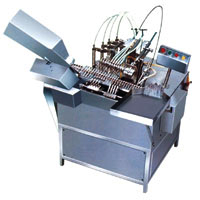

Four Head Ampoule Filling Sealing Machine

Four Head Ampoule Filling Sealing Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules

Features

» Compact GMP model »Production output ranging from 50 to 100 ampoules/minute

» All contact parts made from AISI SS 316 & other Non-contact parts made from AISI SS 304.

» Ampoule neck centering during gas flushing and filling operations

» Machine is suitable to fill 1ml to 10ml ampoules with the help of change Parts

» Possibility of Nitrogen Gas flushing before & after filling

Six Head Ampoule Filling Sealing Machine

Six Head Ampoule Filling Sealing Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

Features

» Compact GMP model

»Production output ranging from 60 to 150 ampoules/minute

» All contact parts made from AISI SS 316 & other Non-contact parts made from AISI SS 304.

» Ampoule neck centering during gas flushing and filling operations

» Machine is suitable to fill 1ml to 10ml ampoules with the help of change Parts

» Possibility of Nitrogen Gas flushing before & after filling

Eight Head Ampoule Filling Sealing Machine

Eight Head Ampoule Filling Sealing Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

Features

» Compact GMP model

»Production output ranging from 120 to 200 ampoules/minute

» All contact parts made from high quality Stainless Steel 316L & other Non-contact parts made from Stainless Steel 304

» Ampoule neck centering during gas flushing and filling operations

» Possibility of nitrogen gas flushing before, during and after filling

» Machine is suitable to fill 1ml to 10ml ampoules with the help of change Parts

Ampoule Vial Jet Washing Machine

OUT PUT/ CYCLE :- Each Cycle time will be of approximately 60 seconds . Depending on the operator’s efficiency & method of Ampoule & Vial loading, 30 cycle/hour can be achieved. Further, Ampoule/Vial size and corresponding Multi Jet Needle Plate will decide the total output

Multi Jet Needles Max. Ampoule Size(ml) up to Max. Vial Size(ml) up to

340 1 to 5ml 002

240 1 to 5ml 003

189 1 to 25ml 5/10

149 1 to 25ml 5/10/20

100 1 to 25ml 5/10/20/30

056 1 to 25ml 100

Ampoule Inspection Machine

Ampoule & Vial Jet Washing Machine is a simple, compact, versatile and a reliable ampoule/vial washing machine complies as per GMP requirements.

Features

» Compact GMP model

» Suitable for 1ml to 5ml ampoules

» All contact parts are made from stainless Steel.

» Spinners equipped with ampoule holder to detect cracks, charring on the mouth of the ampoules.

» Spinners equipped with ampoule holder to detect cracks, charring on the mouth of the ampoules.

»Minimize breakage of ampoules due to adequate bearing points on spinners.

Ampoule Sticker Labeling Machine

Automatic Ampoule Labeling Machine is suitable for label on filled & sealed ampoules.

Features

» High Production Speed up to 250 containers per minute.

»S.S. 304 Constructions.

»Micro processor Control unit with LCD Display.

»Full Pharmaceutical security system. Secondary Pressing unit.

» Imported Gear Motor for Conveyor & Pressing unit

» Programmable HMI Unit

» In built Speed Indicator & Counter

Double Stroke Filling Sealing Machine

Double Stroke Ampoule Filling Sealing Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

Features

» Compact GMP model

»Production output ranging from 30 ampoules/minute to 150 ampoules/minute

» All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

» Machine is suitable to fill 1ml to 20ml ampoules and minimum change over parts from 1ml to 20ml ampoule size

» Ampoule neck centering during gas flushing and filling operations

» Possibility of nitrogen gas flushing before, during and after filling

Four Stroke Filling Sealing Machine

our Stroke Ampoule Filling Sealing Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

Features

» Compact GMP model

»Production output ranging from 30 ampoules/minute to 150 ampoules/minute

» All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

» Machine is suitable to fill 1ml to 20ml ampoules and minimum change over parts from 1ml to 20ml ampoule size

» Ampoule neck centering during gas flushing and filling operations

» Possibility of nitrogen gas flushing before, during and after filling

Glass Ampoule Filling Machine

Glass Ampoule Filling Sealing Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

Features

» Compact GMP model

»Production output ranging from 30 ampoules/minute to 150 ampoules/minute

» All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

» Machine is suitable to fill 1ml to 20ml ampoules and minimum change over parts from 1ml to 20ml ampoule size

» Ampoule neck centering during gas flushing and filling operations

Cosmetic Ampoule Filling Sealing Machine

Cosmetic Ampoule Filling Sealing Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

Features

» Compact GMP model

»Production output ranging from 30 ampoules/minute to 150 ampoules/minute

» All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

» Machine is suitable to fill 1ml to 20ml ampoules and minimum change over parts from 1ml to 20ml ampoule size

» Ampoule neck centering during gas flushing and filling operations

» Possibility of nitrogen gas flushing before, during and after filling

Highspeed Ampoule Filling Sealing Machine

Highspeed Ampoule Filling Sealing Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

Features

» Compact GMP model

»Production output ranging from 30 ampoules/minute to 150 ampoules/minute

» All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

» Machine is suitable to fill 1ml to 20ml ampoules and minimum change over parts from 1ml to 20ml ampoule size

» Ampoule neck centering during gas flushing and filling operations

» Possibility of nitrogen gas flushing before, during and after filling

Vial Filling And Stoppering Machine

Vial Filling and Stoppering Machine Machine is made in pleasing matt finished stainless steel materials suitable for filling, rubber stoppering and cap sealing of glass vials.

Features

» Suitable for the filling Volume of 2ml to 100ml.

» Piston pump/Peristaltic pump aseptic filling.

» Filling accuracy of ±0.5% to ±1%.

» three operations (Filling, Bunging & Cap Sealing) on single platform.

» All Contact Parts Made from Stainless Steel 316L & framework by Stainless Steel 304.

» Variable A.C. frequency drive for speed adjustment.

Vial Filling And Sealing Machine

Vial Filling and Sealing Machine Machine is made in pleasing matt finished stainless steel materials suitable for filling, rubber stoppering and cap sealing of glass vials.

Features

» Suitable for the filling Volume of 2ml to 100ml.

» Piston pump/Peristaltic pump aseptic filling.

» Filling accuracy of ±0.5% to ±1%.

» three operations (Filling, Bunging & Cap Sealing) on single platform.

» All Contact Parts Made from Stainless Steel 316L & framework by Stainless Steel 304.

» Variable A.C. frequency drive for speed adjustment.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.