AARVI MARKETING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AARVI MARKETING P.LTD.

Fiber Glass Surface Mat

Surface mat is manufactured similar in appearance to the chopped strand mat but is much finer. it is composed of fine fiberglass strands of various lengths randomly dispersed in all directions held together by a resin soluble binder. This material is used to provide a resin-rich layer in liquid or chemical holding tanks, or as a reinforcement for layers of gelcoat. This material is sold by the running sq. meter

Product Description

30GSM Fiberglass Surface Mat is mainly used in the surface layers of FRP products. The min width can be 5cm for pipe joint. Mainly used on pipe and tank winding process, it can improve the product surface property on corrosion resistance, compressive strength, seepage resistance, and longer service life.

It is chiefly used in the product with complicated geometric curve, it has the advantages of good pattern fitness, quick resin impergnation, it can raise the intensity and corrosion resistance of products.

Properties:

- Excellent fiber distribution.

- Smooth surface appearance of finished products.

- Corrosion resistant.

- Low binder content.

- Good molding properties.

Fiber Glass Tape

Woven with the fiberglass, had good insulation and heat resistance, extensively apply to building, waterproof ,antiseptic and wraping up the coil of electrical machinery and electrical apparatus. fiberglass tape is an excellent substitute for asbestos tape.

Fiberglass tape abbreviated as non-alkali tape is woven of non-alkali fiberglass, With its feature of thermal resistance and insulation.drywall fiberglass tape can be used as the bindings of boiler for electrical machinery and appliances.

The drywall fiberglas tape product offers high resistance to temperature , insulation rebate, erosion resistance, heat preservation, environmentally friendly, sound insulation, good filtration vista performance and so on.

Application: It is recommended for wrapping tracer steam lines, the hose piping, exhaust manifold insulation wrap, tadpole tapes,head gasket, and strip curtains for high temperature

The unit will directly sell its product to the market. The company will sell its products all over India and other parts of the world.

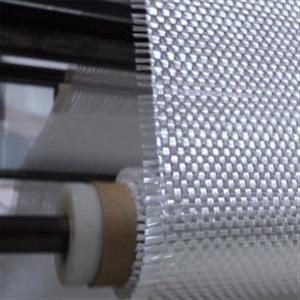

Fiber Glass Woven Roving

Woven Roving Fabrics provide the most economical solution for raising glass content of laminates and increasing laminate stiffness and impact resistance without adding thickness, weight, or other non-reinforcing materials. The fabric delivers costeffective solutions to your competitive reinforcement challenges, particularly large parts such as boat hulls and high-durability laminates such as underground storage vessels.

These Woven Rovings are used in:

· Economical, multi-use fabric Lower finished part cost

· Consistent glass loading Excellent laminate properties and cost-effective reinforcement

· Excellent dimensional stability Ease of handling and drape ability

· Regular porosity Rapid wet-out and fast application

· Assorted weave patterns and preferential fiber loading Design flexibility and engineered strain values

· Crimp engineered for end-use High impact response

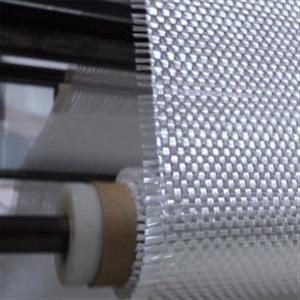

Fiber Glass Cloth

It’s a closely-woven cloth fabricated of glass fibers; often used as a finishing jacket over thermal insulation for piping.

General Description: Woven fiberglass cloths are very common for marine & composite construction and repair. Light weight cloths tend to provide a smooth finish and are excellent for producing a waterproofing layer over wood or other surfaces when combined with the appropriate resin. Heavier cloths will provide greater strength and overall rigidity. All of our fiberglass cloths are compatible for use with our polyester resins, epoxy resins or vinyl ester resin.

The versatility of glass as a fiber makes it a unique industrial textile material. Fiber glass in fabric form offers an excellent combination of properties from high strength to fire resistance. Wide ranges of yarn sizes and weave patterns provide huge number of design potential allowing the end user to choose the best combination for material performance, economics and product flexibility.

Properties of Fiber Glass Cloth:

· Dimensional Stability: Fiber glass is a dimensionally stable engineering material. Fiber glass does not stretch or shrink after exposure to extremely high or low temperatures. The maximum elongation for "E" glass at break is 4.8% with a 100% elastic recovery when stressed close to its point of rupture.

· Moisture Resistance: Glass fibers do not absorb moisture, and do not change physically or chemically when exposed to water.

· High Strength: the high strength-to-weight ratio of fiber glass makes it a superior material in applications where high strength and minimum weight are required. In textile form, this strength can be unidirectional or bidirectional, allowing flexibility in design and cost.

· Fire Resistance: Fiber glass is an inorganic material and will not burn or support combustion. It retains approximately 25% of its initial strength at 1000 deg F (540 deg C).

· Chemical Resistance: most chemicals have little or no effect on glass fiber. The inorganic glass textile fibers will not mildew, rot or deterioriate. Glass fibers are affected by hydrofluoric, hot phosphoric acids, and strong alkaline substances.

· Electrical Properties: fiber glass is an excellent material for electrical insulation. The combination of properties such as low moisture absorption, high strength, heat resistance and low dielectric constant makes fiber glass fabrics ideal as reinforcement for printed circuit boards and insulating varnishes.

· Thermal Conductivity: Low coefficients of thermal expansion combined with high thermal conductivity properties make glass fabric a dimensionally stable material that rapidly dissipates heat as compared to asbestos and organic fibers.

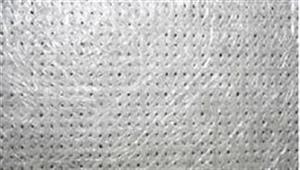

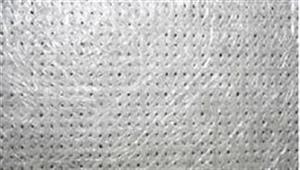

Surface Veil

A synthetic veil is an essential component in the majority of fabricated composite parts. Whether used to enhance the corrosion layer in filament wound or moulded FRP pipes and tanks or to give a high quality surface finish and reduced print through in processes such as pultrusion and continuous laminating, Syntex SLA 45 is the ideal choice combining cost-effectiveness and processability.

Features

- Light weight.

- Binder free.

- Near square properties .

- Fine aperture

Benefits

- High chemical and UV resistance.

- Low resin uptake, minimal effect on final part weight.

- Complete compatibility with all resin systemsReadily conforms to complex shapes.

- High strength in all directions.

- Rapid wet out combined with excellent surface finish.

Applications include:-

- High quality surface finish

- High surface resin content

- Reduced print through of reinforcement structure

- Improved chemical and UV resistance

- Reduced pulling forces in pultrusion processes

- Fully compatible with all reinforcing laminates

Glass Fibre Yarn

The general advantages of glass fibers

MECHANICAL STRENGTH: Glass filament has a greater specific resistance (tensile strength/volumetric mass) than steel. This characteristic is the primary reason for the use of glass strand in the production of high performance composites.

ELECTRICAL CHARACTERISTICS: Glass filament is used for a wide variety of applications because of its properties as an excellent electrical insulator, even at low thickness, combined with its mechanical strength and behavior in different temperatures.

INCOMBUSTIBILITY: As a mineral material, glass strand is naturally incombustible. It neither propagates nor supports a flame. When exposed to heat, it emits neither smoke nor toxic products.

DIMENSIONAL STABILITY: Glass filament is insensitive to variations in temperature and hygrometry and has a low coefficient of linear expansion.

COMPATIBILITY WITH ORGANIC MATRICES: The ability of glass strand to accept different types of size, which creates a bond between the glass and the matrix, and enables it to be combined with many synthetic resins, as well as certain mineral matrices (plaster, cement).

NON-ROTTING: Glass filament does not deteriorate or rot and is not affected by the action of insects and rodents.

LOW THERMAL CONDUCTIVITY: This characteristic is highly valued in the building industry, where the use of glass strand composites makes it possible to eliminate thermal bridging, enabling considerable heat savings.

DIELECTRIC PERMEABILITY: This is essential in applications such as radomes, electromagnetic windows and more.

INTEGRATION OF FUNCTIONS: Glass strand composite material can be used to produce one-piece parts, which integrate several functions and replace several assembled parts.

HIGH RESISTANCE TO CHEMICAL AGENTS: When combined with appropriate resins, composites with this characteristic can be made from glass filament.

The general advantages of composites reinforced with glass strands

LIGHTNESS: Reinforced plastic parts help save weight compared to steel parts (up to 30% lighter) with similar thermo-mechanical properties.

EASY TO SHAPE: Glass strands help reinforce parts with multiple sizes and shapes, from vessels to hollow parts (pipes), pultruded and long parts, complex parts (inlet manifold or electrical components, façade decoration) and small or very thin parts (electrical cables, printed circuit boards).

INTEGRATION OF FUNCTIONS: One of the main advantages of composites is that a part with multiple functions can be made in a single step. By combining complexity of shapes, lightness, dimensional accuracy, high thermo-mechanical properties and reliability, composites meet new functional needs for motor vehicles.

DIELECTRIC AND THERMO-MECHANICAL PROPERTIES: Composite parts and materials, including glass strands, demonstrate many performances: tensile strength, flexural impact strength, compression strength, interlaminar shear strength, fire resistance, deflection under load, water absorption, moisture absorption, resistance to cracking, breaking, splitting, abrasion, corrosion resistance and chemical resistance.

IMPROVEMENT IN SURFACE FINISH: Glass reinforcements (mats, tissues), when added or molded with other materials, help improve their surface aspect as they allow a uniform impregnation (with resins) and are not subject to cracking, breaking or splitting.

RECYCLABILITY: Owing to different technical methods, recycling of glass strand is now possible, as is the recycling of thermoplastic or thermoset glass reinforced parts.

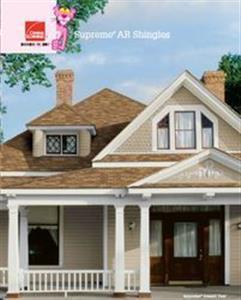

Supreme A.R. Shingles

Supreme® shingles are the smart choice when you want to balance curb appeal, weather resistance and value.

Supreme® Shingles in the Shasta White color are ENERGY STAR® rated. They can help reduce energy use by keeping roof temperatures cooler, decreasing the amount of air conditioning needed to keep your home cool, lowering carbon dioxide emissions, and reducing heat island effect and smog. They also offer:The industry’s highest fire rating – Class A UL Fire Rating

Add an attractive finished look to your roof with Hip & Ridge Shingles

25-Year Limited Warranty*

60-MPH Wind Resistance Limited Warranty*

Algae Resistance Limited Warranty*Not only do they increase the character and curb appeal of your home, but they also provide excellent protection to your roof's peak. Owens Corning™ Hip & Ridge Shingles are uniquely color matched for Supreme®Shingles and provide an important finishing element to your roof.

Oakridge Shingles

Make it your own.

When does a house become a home? When the place you live in begins to reflect the life you’re living. When every change,both big and small, makes it more and more your own. Choosing a new roof is your opportunity to make a major impact on the look of your home — and we’re here to help. Owens Corning has been a leader in the building materials industry for over 70 years.So you can be confident that your new roof will enhance and help protect your home for years to come.

ENERGY STAR® is for roofs too.Similar to the energy-efficient appliances in your home,roofing products can provide energy-saving qualities.Owens Corning™ Oakridge® Roofing Shingles in Shasta White can help reduce your energy bills when installed properly. These shingles reflect solar energy, decreasing the amount of heat transferred to a home’s interior — and the amount of air conditioning needed to keep it comfortable. Actual savings will vary based on geographic location and individual building characteristics.

Product Attributes

Warranty Length*Limited Lifetime‡ (for as long as you own your home)

Wind Resistance Limited Warranty*110/130** MPH

Algae Resistance Limited Warranty*10 Years

Tru PROtection® Non-Prorated Limited Warranty* Period*10 Years

Owens Corning™ Roofing Hip & Ridge Shingles do more than just deliver added protection to the most vulnerable areas of your roof — they enhance the roofline and help define the character of your entire home.Don’t accept a generic substitute. Be sure to choose the right Owens Corning™ Roofing Hip & Ridge style and specially matched color to provide the perfect finishing touch to your new roof.

Tru Defination Duration Shingles

TruDefinition® Duration® Shingles with patented SureNail® Technology offer a high-end, premium look, which gives your home the aesthetics you desire, at an attractive price. Available in popular colors, TruDefinition®Duration® Shingles provide:

A Limited Lifetime Warranty*/† (for as long as you own your home)

130-MPH Wind Resistance Limited Warranty*

Bold, lively contrast

Complementary shadow lines and greater dimension

Not only do they increase the character and curb appeal of your home, but they also provide excellent protection to your roof's peak. Owens Corning™ Hip & Ridge Shingles are uniquely color matched for TruDefinition®Duration® Shingles and provide an important finishing element to your roof.

Cemfil Anti Crack Hd Concrete And Mixers Alkali Resistant Chopped Strand

PRODUCT DESCRIPTION

Anti-Crak® HD (High Dispersion) is an engineered AR-glass chopped strand designed for mixing in concrete and all hydraulic mortars.

PRODUCT APPLICATION

Anti-Crak® HD fibers are typically used at low addition level to prevent cracking & improve the performance of concrete, flooring, renders or other special mortar mixes. They incorporate easily into mixes creating a tridimensional homogeneous network of reinforcement in the matrix.

Anti-Crak® HD fibers can be added at the central mixing plant to the wet concrete mix; or directly into the ready-mix truck.

Anti-Crak® HD fibers do not protrude through the surface and require no additional finishing procedures. There inforcement is incorporated in the concrete mass and is invisible on the finished surface.

ADVANTAGES AND BENEFITS:

- Excellent workability

- High Dispersion : 200 million filaments per KG in fiber length 12 mm

- Invisible on the finished surface

- Does not corrode

- Control and prevention of cracking in fresh concrete

- Overall enhancement of durability and mechanical properties of concrete

- Effective at very low dosage

- Homogeneous mix

- Safe and easy to handle

Cemfil Anti Crack Alkali Resistant Glass Macro Fiber

PRODUCT DESCRIPTION:

Anti-Crak® HP 67/36 is a “High Performance” Alkali Resistant glass macro fiber, engineered to reinforce against plastic, thermal and drying shrinkage cracking. Anti-Crak® HP 67/36 increases flexural strength and ductility, and adds toughness, impact and fatigue resistance to the concrete.

Anti-Crak® HP 67/36 can be used as secondary reinforcement and in specific applications also as primary reinforcement.

Anti-Crak® HP 67/36 disperses quickly and evenly throughout the concrete matrix, because the specific gravity is similar to the aggregates used in concrete. This inherent characteristic of glass guarantees high fiber performance throughout the concrete mass.

PRODUCT APPLICATION:

Anti-Crak® HP 67/36 has been specifically designed to replace secondary and primary reinforcement (welded wire reinforcement, light rebar, steel and synthetic fibers) in residential, commercial and industrial slabs-on-ground, compression layers, pavements and precast concrete.

ADVANTAGES AND BENEFITS:

• Alkali resistant glass*

• Control and prevention of cracking in fresh and hard concrete and mortars (plastic shrinkage cracking, drying shrinkage and thermal cracking, service life cracking under load )

• Improves mechanical properties of hardened concrete

• Fast and uniform dispersion during blending

• Does not affect concrete pumpability

• Allow for high dosages without affecting the workability

• Will not corrode

• No additional water demand

• Easy to handle

Cemfil Alkali Resistant Glass Macro Fiber For Repair Mortars And Premix G.R.C.

Product Description:

Anti-Crak® HP 67/36 is a “High Performance” Alkali Resistant glass macro fiber, engineered to reinforce against plastic, thermal and drying shrinkage cracking. Anti-Crak® HP 67/36 increases flexural strength and ductility, and adds toughness, impact and fatigue resistance to the concrete.

Anti-Crak® HP 67/36 can be used as secondary reinforcement and in specific applications also as primary reinforcement.

Anti-Crak® HP 67/36 disperses quickly and evenly throughout the concrete matrix, because the specific gravity is similar to the aggregates used in concrete. This inherent characteristic of glass guarantees high fiber performance throughout the concrete mass.

Product Application:

Anti-Crak® HP 67/36 has been specifically designed to replace secondary and primary reinforcement (welded wire reinforcement, light rebar, steel and synthetic fibers) in residential, commercial and industrial slabs-on-ground, compression layers, pavements and precast concrete.

Advantages And Benefits:

• High integrity during mixing

• Low tex strand

• Easy incorporation

• High performance with low dosage

• Excellent reproduction of detail

• Good level of workability

• Reduced water demand compared to other fibers

• Improves mechanical performance of GRC elements

• Makes highly durable GRC elements

• Safe and easy to handle

Water Dispersible Chopped Strand

This product is made with Advantex® glass fibres. Advantex glass combines the excellent mechanical and electrical properties of traditional E-Glass with the acid corrosion resistance of E-CR-Glass. Advantex glass satisfies the requirements and description of both E-Glass and ECR-Glass according to ISO 2078 and ASTM D 578.

PRODUCT DESCRIPTION

526 chopped strands are made from continuous strands of glass filaments designed to reinforce gypsum, calcium silicate etc. P 526 is treated with starch based water dispersible sizing. P 526 has excellent dry flow coupled with good dispersion. P526 chopped strands are ideal for commercial mass production of gypsum boards, automobile components, refractories & drying system components.

PROPERTIES IDENTIFICATION

Example : EC 6 P526

E : Glass type

C : Continuous process

6 : Nominal length of chop (mm)

P526 : OCV Reinforcements code for sizing system

PRODUCT BENEFITS

• Excellent dry flow characteristics

• Good dispersion

• Short mixing times for improved productivity

• Good mechanical strength

• Anti- crack agent

Available in 6mm (Net weight of bag 25kg) & 12 mm (Net weight of bag 20kg) in moisture proof Kraft paper bags.

Chopped Strand

This product is produced using Advantex® glass fiber. Advantex glass fiber combines the electrical and mechanical properties of traditional E glasses with the acid corrosion resistance of E-CR glass.

PRODUCT DESCRIPTION

P546 chopped strands are made from continuous strands of glass filaments designed to reinforce Phenolic grade resins. P 546 is specially designed to be compatible with phenolic resins based on silane coupling agent. P 546 has excellent dry flow coupled with good dispersion.P546 Is particularly suitable for producing BMC premix for friction applications and phenolicthermosets by compression or by injection moulding.

PRODUCT APPLICATION

P546 is ideal for commercial mass production of friction facings, electrical & electronic equipment components etc.

IDENTIFICATION

Example: EC 6 P546

E -Glass type

C -Continuous process

6 -Nominal length of chop (mm)

P546 - OCV code for sizing system

PRODUCTS & PACKAGING AVAILABLE

P 546 is available in 3, 4.5, 6 and 12mm. 20-25 Kgs. in moisture proof polyethylene bags and packed in a cardboard carton or Kraft paper bag.

Chopped Strand For B.M.C.

Product Description:

979 is a high performance chopped strand reinforcement engineered for optimum performance in BMC compression,injection and transfer molding applications. 979 sizing is specially formulated for maximum compatibility with polyester and vinylesterresin systems.979 chopped strand reinforcements can be used in a wide variety of applications including appliance components, automotive headlight reflectors and valve covers; electrical junction boxes and switch components; hand tool housing, sinks and countertops.

Product Reference

Example : EC 14 6 mm 979

E : Glass type

C : Type of process: continuous

14 : Filament diameter (μm)

6 : nominal length of chop

979 : OCV™ Reinforcements code for sizing system

Features and PRODUCT Benefits:

• Easy mixing into the resin

• Because of their whiteness 979 chopped strands do not color the compound

• No pollution, e.g. colored particles

• Improved mechanical properties in both compression-molded and injection-molded parts.

Chopped Strands

183F is a high performance chopped strand reinforcement engineered for optimum performance in several Thermoplastic and Thermoset resin systems. 183F works well in Thermoplastic polyester (PBT), PET and PCT.

In addition, 183F works well in Thermoset phenolics as well as epoxies.

Product Reference:-

DS3183F-13C, 183F-14C, 183F -11C, 183F-14P

Glass Type: Advantex® - Boron Free

Process Type: Continuous Filament

Diameter: 14μm, 13μm, 11μm (Micrometer)

Chop length: 4mm

Features and PRODUCT Benefits:-

• Excellent dispersion.

• Improved quality.

• Excellent resin compatibility.

• Good composite mechanical properties.

• Advantex® Glass.

• Good chemical resistance.

• Low fuzz levels.

• Minimum production downtime.

• ISO 9002 certified manufacturing.

• Consistant product.

Thermoplastic Reinforcement Chopped Strand

I. DESCRIPTION952 chopped strands are obtained by assembling sized E-glass continuous fibers with a nominal diameter of 10 or 13 microns and chopping them to a nominal length of 4.5 mm.To better meet customer needs, 952 chopped strands are also offered in a pelletized (P) form to promote optimum glass handling and feeding characteristics II. USE Owens Corning 952 products are designed for use with Polyester resins: PBT, PET.III. AVAILABLE PRODUCTS Nomenclature Sizing Nominal Diameter Appearance (C/P)ChopLength952-10C 4.5mm95210μmConventional4.5mm952-13C 4.5mm13μm952-10P 4.5mm10μmPelletized

Roving

PRODUCT DESCRIPTION:

495 conventional roving is manufactured with state-of-the-art equipment, innovative chemistry and a major commitment to statistical process control. The quality Management Program of Owens Corning manufacturing is certified as meeting the requirements of ISO 9002. Owens Corning 495 roving is manufactured from a collection of continuous glass filaments gathered, without mechanical twist, into a single bundle. The roving is then wound and shipped in a tubeless package ready for use in cstomer continuous operations.

PRODUCT APPLICATION:

The “495” designation refers to a high performance sizing that has proven world wide acceptance in a multiple range of highly demanding applications such as pipes or tanks for wastewater treatment and chemical outlets. 495 roving is also suitable in panel laminating or can be used as choppable roving in reinforced complexes. The 495 sizing is compatible with polyester and vinyl ester resin systems.

FEATURES:

• Corrosion resistance

• Low static and fuzz/excellent runnability

• High laminate properties

• High package and pallet weight

Roving For S.M.C.

PRODUCT DESCRIPTION:

P204 is an assembled E-glass roving for the manufacture of Sheet Molding Compound (S.M.C.).

P204 sizing is of medium solubility (60%) and contains a silane agent.

P204 is recommended for general purpose compounds and for Low Shrink applications; it can also be used for Low Profile applications.

PRODUCT REFERENCE:

Example : EC 2400 P204

E : Glass type

C : Continuous process

2400 : Roving linear weight (tex)

P204 : OCV™ Reinforcements code for sizing system

FEATURES AND PRODUCT BENEFITS:

• Excellent processability:- easy unwinding and chopping- good strands distribution- no fuzz- no static electricity

• Very good properties of molded parts (no coloration, highly pigmentable, good mechanical properties)

• Easy wet-out and impregnation

Multi End Roving For S.M.C.

PRODUCT DESCRIPTION:

P215 is a multi-end roving, manufactured from a collection of continuous glass strands which are gathered, without mechanical twist, into a single bundle. The roving is then wound and shipped as a tubeless package ready for use at customer operations. P215 roving is manufactured with state-of-the-art equipment, innovative chemistry and with a major commitment to statistical process control. OCV Reinforcements uses a Quality Management System certified to meet ISO 9002 standards.

PRODUCT APPLICATION:

P215 is a multi-end E-glass roving with low sub-tex, designed for the manufacture of Sheet Molding Compound (SMC). P215 sizing is of medium solubility (60%) and contains a Silane coupling agent. Due toits outstanding characteristics, P215 roving is particularly recommended for application where very good surface aspect is requested.

Roving For Translucent Panels

PRODUCT DESCRIPTION:

P243 is a roving produced by assembling Advantex® glass strands,wound without twist onto cylindrical cheeses. It is specially designed for the manufacture of translucent panels, using all types of cutters. P243 has a sizing system with a silane coupling agent.The Advantex® glass fiber combines the electrical and mechanical properties of traditional E-glass with the acid corrosion resistance of E-CR glass.

PRODUCT REFERENCE:

Example : EC 2400 P243

E : Type of glass

C : Continuous process

2400 : Roving linear weight (tex)

P243 : OCV™ Reinforcements code for sizing system

FEATURES AND PRODUCT BENEFITS:

• Very good unwinding at all the usual speeds for this application

• Good splitting and cutting of the strands with good fiber distribution

• Negligible static build-up under normal ambient conditions(temperature between 15 and 35°C, and relative humidity between 35 and 85%)

• Very good wet-out and impregnation

• Excellent translucency of laminates with all usual resin systems

Roving For Chopping

P244 is a roving produced by assembling Advantex® glass strands, wound without twisting into cylindrical cheeses. P244uses a sizing system (medium solubility type) with a silane coupling agent.

P244 is designed for applications such as:

- headliners reinforcement

- the manufacture of panels, complexes and felts

- plaster reinforcement

The Advantex® glass fiber combines the electrical and mechanical properties of traditional E-glass with the acid corrosion resistance of E-CR glass.

Product REFERENCE:

Example : EC 2400 P244

E : glass type

C : continuous process

2400 : roving linear weight (tex)

P244 : OCV™ Reinforcements code for sizing system

Features and PRODUCT Benefits:

• Excellent process ability

• Easy wet-out and impregnation

• Easy unwinding and chopping

• Very good properties of molded parts (no coloration,highly pigmentable, good mechanical properties)

• Good strand distribution

• No fuzz

• No static electricity

Epikote Pultrusion Thermal Curing Epoxy Resin

Applications:

Epikotetm System 273 consists of a highly pure Bisphenol-A-epoxy-resin and Dicarboxylic- Anhydride-hardener.

In combination with Heloxytm Modifier PF and accelerator Epikotetm Catalyst 100, the Epikotetm System 273 is a versatile cast resin system formany medium voltage applications.

Epikotetm System 273 is outstandingly suitable for filament winding in addition with the accelerator Epikotetm Catalyst 100 or Epikotetm Catalyst 101 (0.5- 2 pbw).

Shelf Life

At 20 °C 12 months

Important: Keep cool and protect from sun.

Product-Features

- Multi purpose system for impregnation and casting

- Low viscosity

- Long pot life

- Customer individual modifying by adding HELOXYTM Modifier PF

- Good mechanical and electrical properties

Epikote E.L. Epoxy Resins

Product Description:

Epikote Resin 828EL is a medium viscosity liquid epoxy resin produced from bisphenol A resin and epichlorohydrin. It contains no diluent. The principal feature of this resin is its low hydrolysable chlorine content.

Application Areas/Suggested Uses

EPIKOTE 828EL has been designed for applications in the electrical and electronics industries (e.g.casting, encapsulating, etc.) which require a resin with low hydrolysable chlorine.

Benefits

l Low hydrolysable chlorine

l Medium viscosity

l Good pigment wetting

l Imparts high mechanical performance

l Imparts good chemical resistance

Epikote X.A. Epoxy Resin

Product Description

Epikote Resin 828XA is a medium viscosity epoxy resin produced from bisphenol A and epichlorohydrin.It contains no diluent. Epikote 828XA provides good pigment wetting, good resistance to filler settling anda high level of mechanical and chemical resistance properties. As judged by laboratory tests, EPIKOTE828XA is considered to have a good resistance to crystallization on storage. In this respect EPIKOTE828XA is superior to Epikote Resin 827, 828LV or 828. However, the addition of reactive diluents e.g. inthe production of formulated compositions, tends to reduce the crystallization resistance.

Application Areas/Suggested Uses

Building and civil engineering industries (floorings, adhesives, mortars, grouts). Used for general composite application and in solvent-free or high-solids coatings.

Benefits

l Improved crystallisation resistance

l Good pigment wetting

l Imparts high mechanical performance

l Imparts good chemical resistance

Epikote Epoxy Resins

Product Description

EPIKOTE Resin 828 is a medium viscosity liquid epoxy resin produced from bisphenol A resin and epichlorohydrin. It contains no diluent. EPIKOTE 828 provides good pigment wetting and good resistance tofiller settling and a high level of mechanical and chemical resistance properties in cured state. However, asan unmodified pure bisphenol A resin, EPIKOTE 828 is prone to crystallize on storage, particularly in cold conditions (see bulletin EK 1.5.11 for a description of the laboratory test method used to determine the crystallization tendency of EPIKOTE resins). Note, EPIKOTE 827, 828 and 828 LVEL are unmodified resins of similar type and performance; they offer the formulator a choice of viscosity.

Application Areas/Suggested Uses

Electrical and electronic industries (potting, casting, impregnating). Building and civil engineering industries(floorings, adhesives, mortars, grouts). Filament winding for composites. Solvent free and high-solids coatings.

Benefits:

l Medium viscosity

l Good pigment wetting

l Good resistance to pigment settling

l Imparts high mechanical performance

l Imparts good chemical resistance

Derakane Momentum Epoxy Vinyl Ester Resin

Derakane Momentum 411-350 epoxy vinyl ester resin is based onbisphenol-A epoxy resin and provides resistance to a wide range of acids, alkalis,bleaches, and organic compounds for use in many chemical processing industry applications. DERAKANE MOMENTUM resins are a new generation of resins that can be used to improve fabrication efficiency and product quality. Their lighter color makes defects easier to see and correct while the resin is still workable. The resin’s improved reactivity properties often permit an increase inthe lay -up thickness per session. The longer shelf life provides additional flexibility to fabricators in storage and handling.

Application and fabrication techniques:

· FRP storage tanks, vessels, ducts, and on-site maintenance projects, particularlyin chemical processing and pulp and paper operations.

· The resin is designed for ease of fabrication using hand lay -up, spray -up, filament winding, compression molding and resin transfer molding techniques, pultrusionand molded grating applications.

· An alternate viscosity, optimized for some vacuum infusion processes, is available as DERAKANE MOMENTUM™ 411-100 resin.

Benefits:

· Provides resistance to wide range of acids, alkalis, bleaches, and solvents.This resin holds up in corrosive environments, postponing the need for equipment replacement.

· Tolerates heavy design loads without causing failure due to resin damage.This facilitates working with large weight -bearing equipment with confidence.

· Superior elongation and toughness provides FRP equipment with better impact resistance and less cracking due to cyclic temperature, pressure fluctuations, and mechanical shocks providing a safety factor against damage during process upsets or during shipping installation.

· When properly formulated and cured, complies with FDA regulation, covering materials intended for repeated use in contact with food.

General Purpose Acetoxy Sealant

GE 2000 is an acetoxy cure, one part ready-to-use silicone sealant, designed for cost effective, general purpose glazing and sealing applications. It has outstanding adhesion to non porous surfaces such as glass, glazed surfaces and metal. The sealant's short tooling time and fast cure time ensure fast adhesion, build-up and job completion.

Applications - General sealing & assembly,cap beeding, Windows, doors, siding, trim, molding, baseboards, vents, around wires/pipes, and other attic/ basement applications.

Adheres to most wood, metal, vinyl siding, drywall/plaster, glass, most ceramic, laminates and plastic.

Acetoxy Silicone Sealant

Winsil 10 is an acetoxy cure, one part ready-to-use silicone sealant, designed for cost effective, general purpose glazing and sealing applications. It has outstanding adhesion to non porous surfaces such as glass, glazed surfaces and metal. The sealant's short tooling time and fast cure time ensure fast adhesion, build-up and job completion.

Applications - General sealing & assembly, cap beeding, windows, doors, siding, trim, molding, basboards, vents, around wires/pipes and other attic/basement applications.

All Purpose Neutral Silicone Sealant

Alusil silicone is a one part, low modulus, fast cure silicone sealant which undergoes a neutral cure when exposed to atmospheric mositure. The resulting rubber like seal exhibits high elasticity and excellent durability against sunlight, UV radiation, rain, snow and temperature extremes. Excellent adhesion to most common building materials such as: glass or glazed surfaces, aluminum and other coated metals, masonry, treated wood, concrete, PVC and many other places.

Standard Colors Available - Black/White/Clear

Weather Silicon Sealant

GE SCS2000 SilPruf is a primerless adhesion sealant desinged for weathersealing applications. Supplied as a paste, SCS2000 is a one-component, medium modulus, neutral cure silicone useful on a wide variety of materials in a new or remedial applications.

Applications - Weather sealing, Expansion joints, etc.

Adheres to glass, polycarbonate, vinyl, numerous plastics, treated, and untreated wood, fluoropolymer and powder coated paints, conversion-coated and anodised aluminum, EIFS, brick, terra-cotta, ceramic and porcelain materials, concrete and natural stones.

Standard Colors Available - Black/Grey/White.

Non Bleed And Non Staining Silicon Sealant

GE SCS9000 SilPruf*NB is a 100% silicone polymer sealant formulated to reduce or eliminate dirt pickup, surface streaking and substance staining. SCS9000 is a premium one-component, medium-modulus, neutral cure silicone sealant useful on a wide variety of materials in new or remedial applications. Supplied as a paste, SCS9000 produces a durable silicone rubber joint sealant.

Appications - Weather Sealing, Expansion Joints, etc.

Adheres to glass, polycarbonate, vinyl, numerous plastics, treated and untreated wood, fluoropolymer and powder coated paints, conversion-coated and anodized aluminum, EIFS, brick, terra-cotta, ceramic and porcelain materials, concrete and natural stones.

Standard Colors Available - Black/Grey/White.

Silglaze Weather Sealant

Silglaze WS is fast curing, medium modules one part Neutral cure silicone sealant that cures to silicone rubber when exposed to atmspheric moisture at room temperature to form a highly elastic rubber seal with excellent adhesion to most common building surfaces: glass or glazed surfaces, painted wood, aluminun and other metals. Silglaze WS is unaffected by high or low temperatures and its superior physical properties are designed to give outstanding durability and performance.

Applications - Weather sealing, Expasion Joints, Perimeter joint sealing of wood, metal, uPVC and coated frames-curtain wall sealing; glass, metal and cladding.

Multi Purpose Weather Silicon Sealant

Winsil 20 is a neutral cure, one part ready-to-use silicone sealant which offers excelllent adhesion to a wide variety of porous substrates such as concrete, masonry, painted wood, etc.

Applications windows, doors, siding, trim, molding, baseboards, vents, around wires/pipes, showers, tubs, sinks, tile, countertops, fixtures and other attic/basement applications.

Adheres to Glass, polycarbonate, most wood, metal, vinyl siding, masonry, brick, concrete, drywall/plaster, ceramic tile, laminate, plastic and granite.

Silicone Structural Glazing Adhesive

UltraGlaze SSG4000 structural glazing adhesive is a one-component, high-strength neutral cure silicone elastomeric adhesive designed and tested for structurally glazed curtain walll applications. The material is supplied as a pastes, which cures into a durable flexible silicone rubber upon exposure to atmospheric moisture.

Applications - UltraGlaze SSG4000 structural glazing adhesive may be an excellent material of choice for use in structural glazing applications such as factory glazing of unitized curtainwall systems or in field constructed stick curtainwall systems. It can also be used as a weather seal product, when movement expected in the join does not exceed its movement capability

High Strength Structural Silicone Sealant

GE SSG4600 Ultra Glaze* is a high strength, 2-part silicone elastomeric adhesive/sealant for use in structural glazing applications, specifically in the fabrication and shop glazing of curtain wall systems. SSG4600 is a two-component product (part A part B) that provides fast adhesion and strength build; when mixed, UltraGlaze cures quickly to a very high strength, tear-resistant durable silicone rubber.

Paintable Hybrid Silicone Weather Sealant

SCS7000 is a neutral single-component,high performance hybrid sealant with excellent weather ability, non staining performance and exceptional paintability for use in both interior &exterior applications.SCS7000 is supplied as a paste which produces a durable, formed-in-placerubber joint sealant upon cure.

Typical Performance Properties

1. Performance

• Weathe rability - Cured sealant exhibits good resistance tonatural weathering for long term performance in both interiorand exterior applications.

• Flexible - 50% movement capacity in both extension and compression.

2. Application

• Excellent Paintability - The cured sealant provides a surfacethat most commercially available paints & coatings will adhereto. SCS7000 can also be painted immediately after application while the sealant is still uncured, or anytime thereafter.

• Versatile Adhesion - Bonds primerless to many substrates including: masonry, brick, terra-cotta, concrete, GFRC, natural stones, glass, plastics, metals, stucco, wood and painted oranodized aluminum.

• Non Slumping - Firm consistency paste with easy tooling characteristics for application to horizontal, vertical or overhead surfaces.

• Low VOC - Significantly lower than the requirements ofthe U.S. Green Building Council’s Leadership in Energy and Environmental Design (L.E.E.D.) program.

• Neutral cure byproduct.

3. Aesthetics

• Nonstaining - Reduces or eliminates the streaking and discoloration on natural stones, glass and aluminum whichcan be caused by some sealants.

Basic Uses

SCS7000 is a candidate to consider:

• When sealing between dissimilar or similar materials in eithernew or remedial weathrproofing applications.

• As a weather-proofing sealant at window perimeters andpunched openings.

• For interior/exterior applications where painting over thesealant is desirable.

Customer Evaluation

Customers must evaluate Momentive Performance Materials(MPM) products and make their own determination as to fitnessof use in their particular applications.

Packaging

SCS7000 is available in 20 fl.oz. (591 ml) foil sausage packsand 2 gallon plastic pails (2 gals. / 7.6 L).

Silicone Elastomeric Coating

GE SilShield SEC 2400 is a high solids , silicone elastomeric coating for use in horizontal and vertical above grade waterproofing applications . SilShield SEC 2400 silicone elastomeric coating can be used to provide a durable, long-term watertight, weatherproof barrier that is not susceptible to color fade, chalking or degradation from natural weathering.

Application - SilShield SEC 2400 silicone elastomeric coating is an architectural coating used as a waterproofing coating in vertical, horizontal and roof applications . SilShield SEC 2400 silicone elastomeric coating can be used in horizontal and roof applications where there is no foot traffic . SilShield SEC 2400 silicone elastomeric coating can be used as a primerless coating on concrete, stucco, masonry, urethane foam, wood, copper, EIFS, aluminum and many painted surfaces . While primerless adhesion is nearly always achieved, adhesion should always be verified by testing a small area prior to the beginning of the project.

SilShield SEC 2400 silicone elastomeric coating is made to order and tinted at the manufacturing facility. Colors can be selected from a pre-matched color fan deck or custom color matching can be performed to specific substrates.

Hot Melt Butyl Sealant

Application:

Mainly used for the production of insulating glass as the first layer elastomeric sealant of insulating glass. It's also offers outstanding adhesion to glass, vinyl, aluminum and other substrates typically used in IG fabrication. Double layer seal insulating glass made by this product has passed the test of China National Glass Quality Supervision.

Request

Callback

Additional Information:

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer),D/P,D/A

- Port of Dispatch: Ex Aslali Ahmedabad

- Delivery Time: Same Day

- Packaging Details: Packing 28 kg Each box

Two Part Insulating Glass Silicone Sealant

IGS 3723 insulating glass sealant is a two-component silicone which cures to form a high strength, high modules sealant exhibiting the following features:

Excellent adhesion to glass, most reflective glass coatings, aluminum and galvanized steel spacers.

Variable ratio allowing for cure rate adjustment.

High application rate at low pumping pressures(reduces pump wear).

Excellent filling and tooling characteristics.

Low sag or slump. Allows use on automatic sealing equipment.

No kit matching required.

Compatible with UltraGlaze* structural glazing sealants.

Non-Flammable curing agent.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.