AARVI MARKETING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AARVI MARKETING P.LTD.

Cemfil Anti Crack Hd Concrete And Mixers Alkali Resistant Chopped Strand

PRODUCT DESCRIPTION

Anti-Crak® HD (High Dispersion) is an engineered AR-glass chopped strand designed for mixing in concrete and all hydraulic mortars.

PRODUCT APPLICATION

Anti-Crak® HD fibers are typically used at low addition level to prevent cracking & improve the performance of concrete, flooring, renders or other special mortar mixes. They incorporate easily into mixes creating a tridimensional homogeneous network of reinforcement in the matrix.

Anti-Crak® HD fibers can be added at the central mixing plant to the wet concrete mix; or directly into the ready-mix truck.

Anti-Crak® HD fibers do not protrude through the surface and require no additional finishing procedures. There inforcement is incorporated in the concrete mass and is invisible on the finished surface.

ADVANTAGES AND BENEFITS:

- Excellent workability

- High Dispersion : 200 million filaments per KG in fiber length 12 mm

- Invisible on the finished surface

- Does not corrode

- Control and prevention of cracking in fresh concrete

- Overall enhancement of durability and mechanical properties of concrete

- Effective at very low dosage

- Homogeneous mix

- Safe and easy to handle

Cemfil Anti Crack Alkali Resistant Glass Macro Fiber

PRODUCT DESCRIPTION:

Anti-Crak® HP 67/36 is a “High Performance” Alkali Resistant glass macro fiber, engineered to reinforce against plastic, thermal and drying shrinkage cracking. Anti-Crak® HP 67/36 increases flexural strength and ductility, and adds toughness, impact and fatigue resistance to the concrete.

Anti-Crak® HP 67/36 can be used as secondary reinforcement and in specific applications also as primary reinforcement.

Anti-Crak® HP 67/36 disperses quickly and evenly throughout the concrete matrix, because the specific gravity is similar to the aggregates used in concrete. This inherent characteristic of glass guarantees high fiber performance throughout the concrete mass.

PRODUCT APPLICATION:

Anti-Crak® HP 67/36 has been specifically designed to replace secondary and primary reinforcement (welded wire reinforcement, light rebar, steel and synthetic fibers) in residential, commercial and industrial slabs-on-ground, compression layers, pavements and precast concrete.

ADVANTAGES AND BENEFITS:

• Alkali resistant glass*

• Control and prevention of cracking in fresh and hard concrete and mortars (plastic shrinkage cracking, drying shrinkage and thermal cracking, service life cracking under load )

• Improves mechanical properties of hardened concrete

• Fast and uniform dispersion during blending

• Does not affect concrete pumpability

• Allow for high dosages without affecting the workability

• Will not corrode

• No additional water demand

• Easy to handle

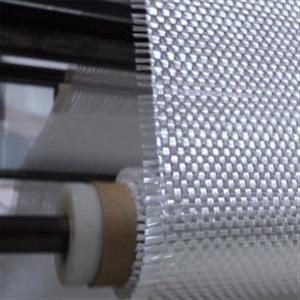

Cemfil Alkali Resistant Glass Macro Fiber For Repair Mortars And Premix G.R.C.

Product Description:

Anti-Crak® HP 67/36 is a “High Performance” Alkali Resistant glass macro fiber, engineered to reinforce against plastic, thermal and drying shrinkage cracking. Anti-Crak® HP 67/36 increases flexural strength and ductility, and adds toughness, impact and fatigue resistance to the concrete.

Anti-Crak® HP 67/36 can be used as secondary reinforcement and in specific applications also as primary reinforcement.

Anti-Crak® HP 67/36 disperses quickly and evenly throughout the concrete matrix, because the specific gravity is similar to the aggregates used in concrete. This inherent characteristic of glass guarantees high fiber performance throughout the concrete mass.

Product Application:

Anti-Crak® HP 67/36 has been specifically designed to replace secondary and primary reinforcement (welded wire reinforcement, light rebar, steel and synthetic fibers) in residential, commercial and industrial slabs-on-ground, compression layers, pavements and precast concrete.

Advantages And Benefits:

• High integrity during mixing

• Low tex strand

• Easy incorporation

• High performance with low dosage

• Excellent reproduction of detail

• Good level of workability

• Reduced water demand compared to other fibers

• Improves mechanical performance of GRC elements

• Makes highly durable GRC elements

• Safe and easy to handle

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.