AARVI MARKETING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AARVI MARKETING P.LTD.

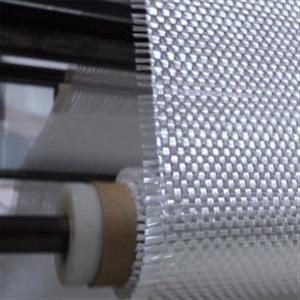

Roving

PRODUCT DESCRIPTION:

495 conventional roving is manufactured with state-of-the-art equipment, innovative chemistry and a major commitment to statistical process control. The quality Management Program of Owens Corning manufacturing is certified as meeting the requirements of ISO 9002. Owens Corning 495 roving is manufactured from a collection of continuous glass filaments gathered, without mechanical twist, into a single bundle. The roving is then wound and shipped in a tubeless package ready for use in cstomer continuous operations.

PRODUCT APPLICATION:

The “495” designation refers to a high performance sizing that has proven world wide acceptance in a multiple range of highly demanding applications such as pipes or tanks for wastewater treatment and chemical outlets. 495 roving is also suitable in panel laminating or can be used as choppable roving in reinforced complexes. The 495 sizing is compatible with polyester and vinyl ester resin systems.

FEATURES:

• Corrosion resistance

• Low static and fuzz/excellent runnability

• High laminate properties

• High package and pallet weight

Roving For S.M.C.

PRODUCT DESCRIPTION:

P204 is an assembled E-glass roving for the manufacture of Sheet Molding Compound (S.M.C.).

P204 sizing is of medium solubility (60%) and contains a silane agent.

P204 is recommended for general purpose compounds and for Low Shrink applications; it can also be used for Low Profile applications.

PRODUCT REFERENCE:

Example : EC 2400 P204

E : Glass type

C : Continuous process

2400 : Roving linear weight (tex)

P204 : OCV™ Reinforcements code for sizing system

FEATURES AND PRODUCT BENEFITS:

• Excellent processability:- easy unwinding and chopping- good strands distribution- no fuzz- no static electricity

• Very good properties of molded parts (no coloration, highly pigmentable, good mechanical properties)

• Easy wet-out and impregnation

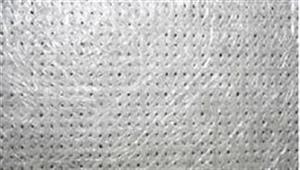

Multi End Roving For S.M.C.

PRODUCT DESCRIPTION:

P215 is a multi-end roving, manufactured from a collection of continuous glass strands which are gathered, without mechanical twist, into a single bundle. The roving is then wound and shipped as a tubeless package ready for use at customer operations. P215 roving is manufactured with state-of-the-art equipment, innovative chemistry and with a major commitment to statistical process control. OCV Reinforcements uses a Quality Management System certified to meet ISO 9002 standards.

PRODUCT APPLICATION:

P215 is a multi-end E-glass roving with low sub-tex, designed for the manufacture of Sheet Molding Compound (SMC). P215 sizing is of medium solubility (60%) and contains a Silane coupling agent. Due toits outstanding characteristics, P215 roving is particularly recommended for application where very good surface aspect is requested.

Roving For Translucent Panels

PRODUCT DESCRIPTION:

P243 is a roving produced by assembling Advantex® glass strands,wound without twist onto cylindrical cheeses. It is specially designed for the manufacture of translucent panels, using all types of cutters. P243 has a sizing system with a silane coupling agent.The Advantex® glass fiber combines the electrical and mechanical properties of traditional E-glass with the acid corrosion resistance of E-CR glass.

PRODUCT REFERENCE:

Example : EC 2400 P243

E : Type of glass

C : Continuous process

2400 : Roving linear weight (tex)

P243 : OCV™ Reinforcements code for sizing system

FEATURES AND PRODUCT BENEFITS:

• Very good unwinding at all the usual speeds for this application

• Good splitting and cutting of the strands with good fiber distribution

• Negligible static build-up under normal ambient conditions(temperature between 15 and 35°C, and relative humidity between 35 and 85%)

• Very good wet-out and impregnation

• Excellent translucency of laminates with all usual resin systems

Roving For Chopping

P244 is a roving produced by assembling Advantex® glass strands, wound without twisting into cylindrical cheeses. P244uses a sizing system (medium solubility type) with a silane coupling agent.

P244 is designed for applications such as:

- headliners reinforcement

- the manufacture of panels, complexes and felts

- plaster reinforcement

The Advantex® glass fiber combines the electrical and mechanical properties of traditional E-glass with the acid corrosion resistance of E-CR glass.

Product REFERENCE:

Example : EC 2400 P244

E : glass type

C : continuous process

2400 : roving linear weight (tex)

P244 : OCV™ Reinforcements code for sizing system

Features and PRODUCT Benefits:

• Excellent process ability

• Easy wet-out and impregnation

• Easy unwinding and chopping

• Very good properties of molded parts (no coloration,highly pigmentable, good mechanical properties)

• Good strand distribution

• No fuzz

• No static electricity

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.