AARVI MARKETING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AARVI MARKETING P.LTD.

Epikote Pultrusion Thermal Curing Epoxy Resin

Applications:

Epikotetm System 273 consists of a highly pure Bisphenol-A-epoxy-resin and Dicarboxylic- Anhydride-hardener.

In combination with Heloxytm Modifier PF and accelerator Epikotetm Catalyst 100, the Epikotetm System 273 is a versatile cast resin system formany medium voltage applications.

Epikotetm System 273 is outstandingly suitable for filament winding in addition with the accelerator Epikotetm Catalyst 100 or Epikotetm Catalyst 101 (0.5- 2 pbw).

Shelf Life

At 20 °C 12 months

Important: Keep cool and protect from sun.

Product-Features

- Multi purpose system for impregnation and casting

- Low viscosity

- Long pot life

- Customer individual modifying by adding HELOXYTM Modifier PF

- Good mechanical and electrical properties

Epikote E.L. Epoxy Resins

Product Description:

Epikote Resin 828EL is a medium viscosity liquid epoxy resin produced from bisphenol A resin and epichlorohydrin. It contains no diluent. The principal feature of this resin is its low hydrolysable chlorine content.

Application Areas/Suggested Uses

EPIKOTE 828EL has been designed for applications in the electrical and electronics industries (e.g.casting, encapsulating, etc.) which require a resin with low hydrolysable chlorine.

Benefits

l Low hydrolysable chlorine

l Medium viscosity

l Good pigment wetting

l Imparts high mechanical performance

l Imparts good chemical resistance

Epikote X.A. Epoxy Resin

Product Description

Epikote Resin 828XA is a medium viscosity epoxy resin produced from bisphenol A and epichlorohydrin.It contains no diluent. Epikote 828XA provides good pigment wetting, good resistance to filler settling anda high level of mechanical and chemical resistance properties. As judged by laboratory tests, EPIKOTE828XA is considered to have a good resistance to crystallization on storage. In this respect EPIKOTE828XA is superior to Epikote Resin 827, 828LV or 828. However, the addition of reactive diluents e.g. inthe production of formulated compositions, tends to reduce the crystallization resistance.

Application Areas/Suggested Uses

Building and civil engineering industries (floorings, adhesives, mortars, grouts). Used for general composite application and in solvent-free or high-solids coatings.

Benefits

l Improved crystallisation resistance

l Good pigment wetting

l Imparts high mechanical performance

l Imparts good chemical resistance

Epikote Epoxy Resins

Product Description

EPIKOTE Resin 828 is a medium viscosity liquid epoxy resin produced from bisphenol A resin and epichlorohydrin. It contains no diluent. EPIKOTE 828 provides good pigment wetting and good resistance tofiller settling and a high level of mechanical and chemical resistance properties in cured state. However, asan unmodified pure bisphenol A resin, EPIKOTE 828 is prone to crystallize on storage, particularly in cold conditions (see bulletin EK 1.5.11 for a description of the laboratory test method used to determine the crystallization tendency of EPIKOTE resins). Note, EPIKOTE 827, 828 and 828 LVEL are unmodified resins of similar type and performance; they offer the formulator a choice of viscosity.

Application Areas/Suggested Uses

Electrical and electronic industries (potting, casting, impregnating). Building and civil engineering industries(floorings, adhesives, mortars, grouts). Filament winding for composites. Solvent free and high-solids coatings.

Benefits:

l Medium viscosity

l Good pigment wetting

l Good resistance to pigment settling

l Imparts high mechanical performance

l Imparts good chemical resistance

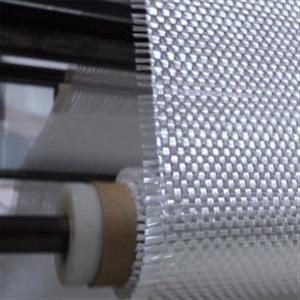

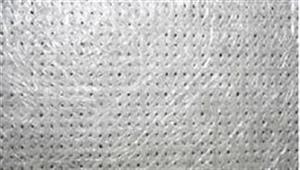

Derakane Momentum Epoxy Vinyl Ester Resin

Derakane Momentum 411-350 epoxy vinyl ester resin is based onbisphenol-A epoxy resin and provides resistance to a wide range of acids, alkalis,bleaches, and organic compounds for use in many chemical processing industry applications. DERAKANE MOMENTUM resins are a new generation of resins that can be used to improve fabrication efficiency and product quality. Their lighter color makes defects easier to see and correct while the resin is still workable. The resin’s improved reactivity properties often permit an increase inthe lay -up thickness per session. The longer shelf life provides additional flexibility to fabricators in storage and handling.

Application and fabrication techniques:

· FRP storage tanks, vessels, ducts, and on-site maintenance projects, particularlyin chemical processing and pulp and paper operations.

· The resin is designed for ease of fabrication using hand lay -up, spray -up, filament winding, compression molding and resin transfer molding techniques, pultrusionand molded grating applications.

· An alternate viscosity, optimized for some vacuum infusion processes, is available as DERAKANE MOMENTUM™ 411-100 resin.

Benefits:

· Provides resistance to wide range of acids, alkalis, bleaches, and solvents.This resin holds up in corrosive environments, postponing the need for equipment replacement.

· Tolerates heavy design loads without causing failure due to resin damage.This facilitates working with large weight -bearing equipment with confidence.

· Superior elongation and toughness provides FRP equipment with better impact resistance and less cracking due to cyclic temperature, pressure fluctuations, and mechanical shocks providing a safety factor against damage during process upsets or during shipping installation.

· When properly formulated and cured, complies with FDA regulation, covering materials intended for repeated use in contact with food.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.