AARVI MARKETING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AARVI MARKETING P.LTD.

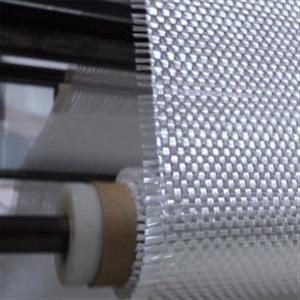

Glass Fibre Yarn

The general advantages of glass fibers

MECHANICAL STRENGTH: Glass filament has a greater specific resistance (tensile strength/volumetric mass) than steel. This characteristic is the primary reason for the use of glass strand in the production of high performance composites.

ELECTRICAL CHARACTERISTICS: Glass filament is used for a wide variety of applications because of its properties as an excellent electrical insulator, even at low thickness, combined with its mechanical strength and behavior in different temperatures.

INCOMBUSTIBILITY: As a mineral material, glass strand is naturally incombustible. It neither propagates nor supports a flame. When exposed to heat, it emits neither smoke nor toxic products.

DIMENSIONAL STABILITY: Glass filament is insensitive to variations in temperature and hygrometry and has a low coefficient of linear expansion.

COMPATIBILITY WITH ORGANIC MATRICES: The ability of glass strand to accept different types of size, which creates a bond between the glass and the matrix, and enables it to be combined with many synthetic resins, as well as certain mineral matrices (plaster, cement).

NON-ROTTING: Glass filament does not deteriorate or rot and is not affected by the action of insects and rodents.

LOW THERMAL CONDUCTIVITY: This characteristic is highly valued in the building industry, where the use of glass strand composites makes it possible to eliminate thermal bridging, enabling considerable heat savings.

DIELECTRIC PERMEABILITY: This is essential in applications such as radomes, electromagnetic windows and more.

INTEGRATION OF FUNCTIONS: Glass strand composite material can be used to produce one-piece parts, which integrate several functions and replace several assembled parts.

HIGH RESISTANCE TO CHEMICAL AGENTS: When combined with appropriate resins, composites with this characteristic can be made from glass filament.

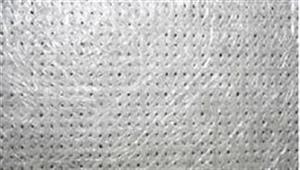

The general advantages of composites reinforced with glass strands

LIGHTNESS: Reinforced plastic parts help save weight compared to steel parts (up to 30% lighter) with similar thermo-mechanical properties.

EASY TO SHAPE: Glass strands help reinforce parts with multiple sizes and shapes, from vessels to hollow parts (pipes), pultruded and long parts, complex parts (inlet manifold or electrical components, façade decoration) and small or very thin parts (electrical cables, printed circuit boards).

INTEGRATION OF FUNCTIONS: One of the main advantages of composites is that a part with multiple functions can be made in a single step. By combining complexity of shapes, lightness, dimensional accuracy, high thermo-mechanical properties and reliability, composites meet new functional needs for motor vehicles.

DIELECTRIC AND THERMO-MECHANICAL PROPERTIES: Composite parts and materials, including glass strands, demonstrate many performances: tensile strength, flexural impact strength, compression strength, interlaminar shear strength, fire resistance, deflection under load, water absorption, moisture absorption, resistance to cracking, breaking, splitting, abrasion, corrosion resistance and chemical resistance.

IMPROVEMENT IN SURFACE FINISH: Glass reinforcements (mats, tissues), when added or molded with other materials, help improve their surface aspect as they allow a uniform impregnation (with resins) and are not subject to cracking, breaking or splitting.

RECYCLABILITY: Owing to different technical methods, recycling of glass strand is now possible, as is the recycling of thermoplastic or thermoset glass reinforced parts.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.