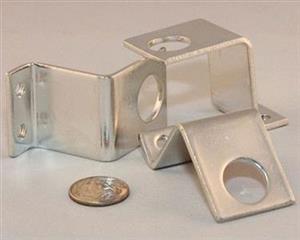

Acid Zinc Plating

Our Acid Zinc Plating are recognized for offering excellent result to customers during usage. Zinc Metal is electro negative to iron and gives excellent corrosion resistance particularly in industrial environment. Zinc is almost always deposited in the fully bright condition where attractive and corrosion resistant finish is required which can be subsequently passivated by Trivalent or Hexavalent chrome in different colors. Sealant can be applied over the passivation to improve salt spray resistance.Coating thickness various from 3~20 Microns. Hydrogen de-embrittlement facility is available for hardened components.