Waste Water Treatment Systems

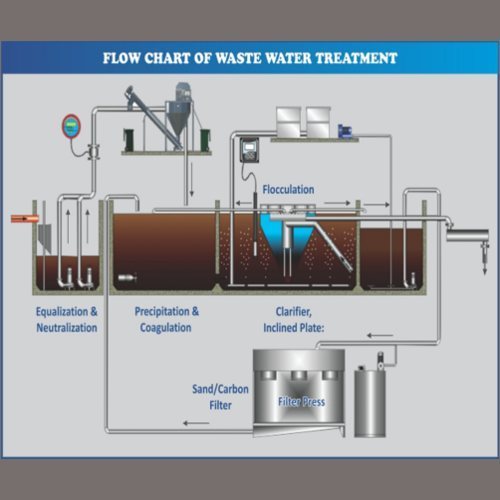

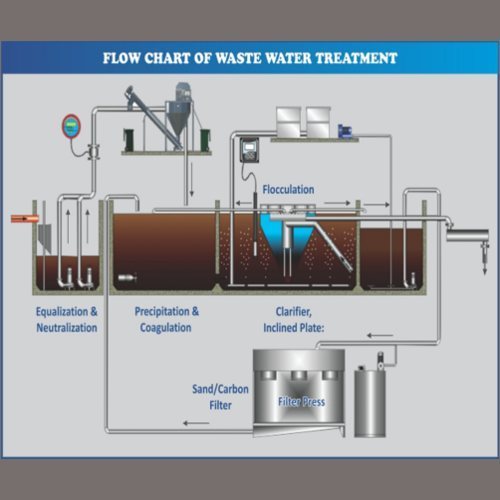

Equalization & Neutralization :

The addition of an EQ tank results in a steady, even, and consistent flow of waste water throughout the system and effluent generally acidic are neutralized with caustic.

Precipitation & Coagulation:

The ionic metals are converted to an insoluble form (particle) by the chemical reaction between the soluble metal compounds and the precipitating reagent.

Flocculation:

The waste water with it’s precipitated pin floc is introduced to the flash mix zone where a polymer flocculation is added.

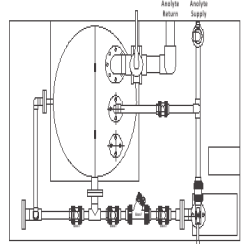

Clarifies, Inclined Plate:

The flocculation waste water is introduced into the clarifies where the settling particles land on the inclined plates and are directed downward and into the sludge chamber.

Filter Press:

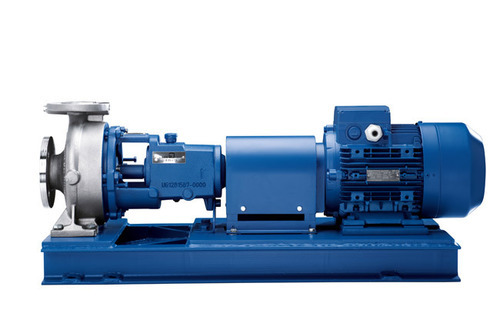

The thickened clarifies sludge is allowed to accumulate sufficiently to provide a full batch for the Filter Press. The filter press is pumped full of the sludge until it is full.

Sand/Carbon Filter:

The water to be discharged finally goes thru these filters which makes final effluent colorless, odorless, free from any organics with very low amount of suspended solids.

Typical industries include:

- Electroplating shops, captive or independent

- Automotive suppliers, trucks, motorcycles etc – Metal to rubber suspension and body parts

- Jewelry mfg

- Machine tool mfg.

- Metal forming such as stamped metal parts that require plating of various types.

- Building materials, cadmium plated nuts, bolts etc. .

- Aerospace

- Wire forming - nails, screws etc

- Appliance makers

- Electronics – gold and silver plating of electrical connectors etc.

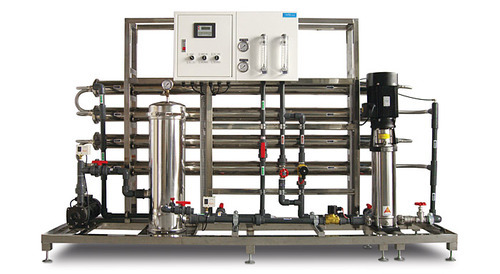

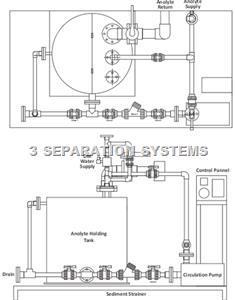

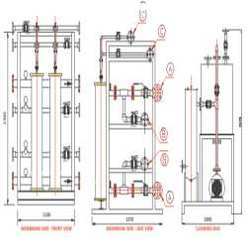

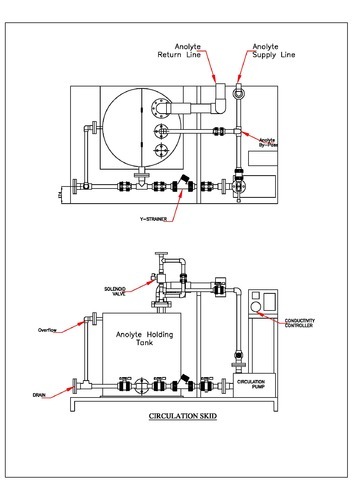

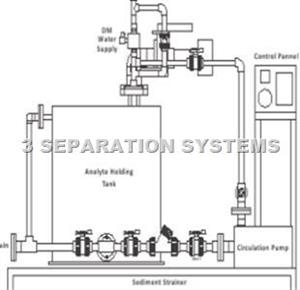

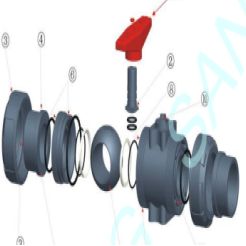

Packaged Systems

3 Separation Systems has a great deal of experience and technical knowledge in designing custom packaged systems for your waste water treatment needs. We dedicate a great deal of time and effort to ensuring that the system we recommend will be a great fit for your application, and will be cost effective as well.

- Fully engineered skid mounted treatment systems are an excellent choice for fully automatic, reliable waste water treatment in a compact, easy to install and use package.

- Systems can be configured for a wide variety of waste water conditions, making them the most versatile systems available.

- Treatment systems come complete with all the components integrated and skid mounted to make a complete waste water treatment system. The integral chemical mixing and separation chambers, automatic pH adjusting system, chamber mixers, chemical pumps, sludge de watering, and system control panel are included.

Chemical Reaction Systems:

We manufactures following reaction systems:

- PH adjustment,

- PH neutralization,

- Multi stage chemical reaction systems

- Flash mix and flocculation systems

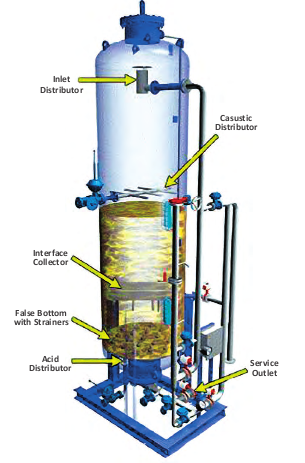

Advanced Wastewater Treatment Solutions:

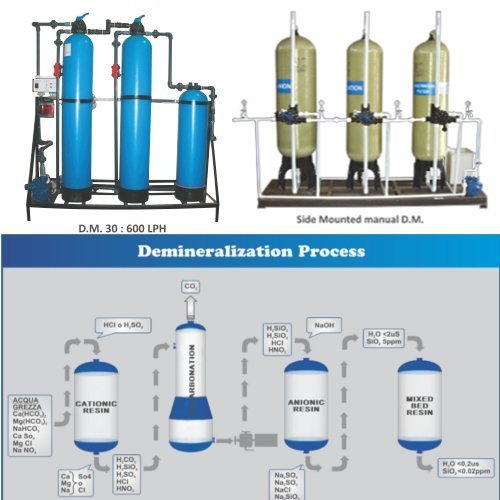

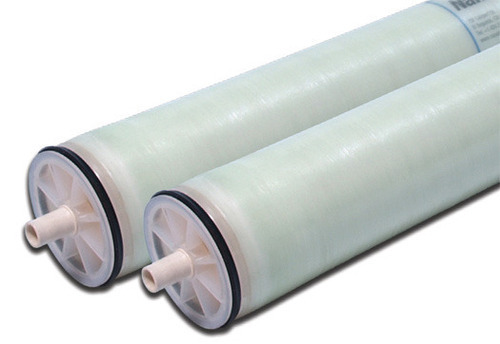

- Ion Exchange

- Disinfection

- Activated Carbon

- Filtration