YO TANA MACHINE TOOLS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to YO TANA MACHINE TOOLS P.LTD.

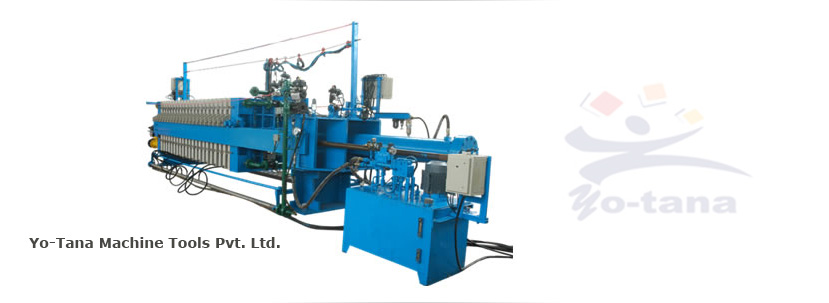

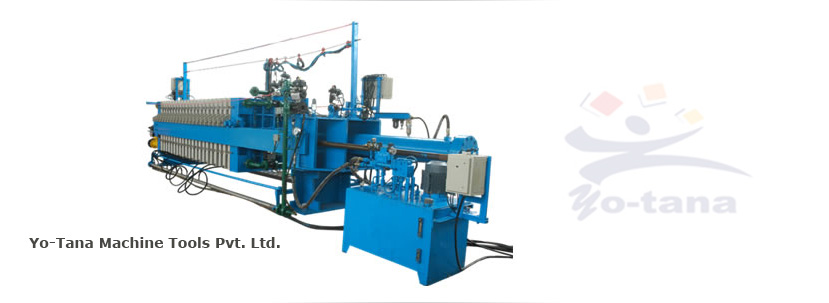

Membrane Filter Press

The initial operation of a membrane filter press is identical to that of its recessed chamber counterpart.

However once the filtration cycle is complete and final filtration pressure is achieved the feed into the filter press is stopped.

At this point the plates within the Filter Press can be inflated using either air or hydraulic pressure to exert a mechanical force on the filter cake retained in the chamber.

The effect of the squeeze is to physically compress the filter cake and force out additional moisture held within the cake giving a drier end result.

Membrane filter plates are used to

Reduce filter cake moisture content

Reduce filtration cycle time

Improve cake washing

This style of filter plate can be installed as

A full plate pack

Alternately in conjunction with recessed companion plates as a more economical option.

Because of its simplicity and flexibility, the chamber Filter Press has been widely applied in clarification and dewatering applications. Membrane Filter Press technology is gaining increased acceptance because it reduces subsequent processing or disposal costs for filter cake. In many applications the membrane Filter Press significantly reduces residual moisture content, making this technology attractive for new plants and for upgrading existing facilities. In both cases the careful selection of plate and membrane materials is essential to the successful performance of the process.

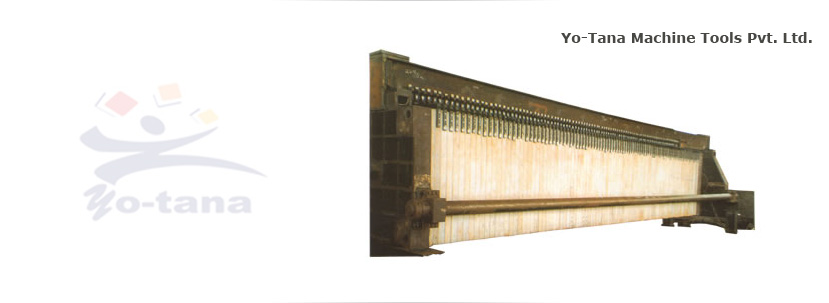

I Beam Type Over Hanging

I-Beam Type Over Hanging

Back to Product

INTRODUCTING NIRMAL POLY PLAST INDUSTRIES

OVERHANGING I –BEAM TYPE FILTER PRESS OF 1500mm X 1500mm SIZE HAVING 90 CHAMBERS

ADVANTAGES BY USING YO – TANA’S OVERHANGING DUAL I – BEAM TYPE FILTER PRESS

Huge Sludge (Solid) Handling capacity upto 10 M.T./Single Batch (Dry).

Easy Handling.

Less Wear & Tear.

Easy Filter Cloth Washing as No Side Bar.

Easy Cake Dropping & Scrapping.

Less Maintenance.

As Plates are Overhanging Type no Handles Sliding on The Side Bars Hence. No Wear & Tear of Side Bars Thereby Increase Strength as Main Supports Are I – Beams on The Top.

Easy Access to the Centre Hole For Cleaning.

Large Treated Water Handling capacity upto 20 Lacks Liers / Day.

Conventional Filter Press

Conventional Filter Press

Back to Product

Filter presses are extensively used to separate solids from liquids in a wide range of applications.

The liquid solid mixture is pumped into the filter press, which is made up of a number of recessed filter plates forming chambers. The plates are supported in a fabricated steel frame and is held closed by a force exerted from a hydraulic ram mounted in the frame work at the end of the machine.

Each filter plate is covered by a filter cloth that retains the solid particles, but allowing the liquid to pass through and exit through the ports in the filter plate.

The particles retained gradually build up on the surface of the filter media and after a period of time eventually form a solid cake.

As the cake forms the pressure within the filter press the pressure rises as the filtrate has to pass through the already partially formed cake to exit the chamber. It becomes increasingly more difficult to continue pumping as the press is unable to accept more solids. At this point the feed pump is stroking infrequently and the filtrate flow from the filter press has considerably reduced or completely stopped.

At this point or at a pre determined filtration time or pressure being achieved the cycle is terminated and the fully formed filter cake is discharged.

P.P Filter Elements

Description / Specification of P.P Filter Elements

We are involved in offering a wide range of P.P Filter Elements to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of P.P Filter Elements. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.