UNITED VAN DER HORST LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to UNITED VAN DER HORST LTD.

Grinding

The three nos. Friedrich Schmaltz-German Make cylindrical grinding machines equipped with CNC controlled, cylindrical cum crank shaft grinding facility. At United Van Der Horst we ensure that jobs are immediately are undertaken for precision grinding. We are capable to ground various jobs with an surface finish accuracy of 0.01 mm i.e. 10 microns.

Capacity : Jobs with diameter up to 1250 mm and lengths in excess of 11 meters are easily accommodated.

Honing

German make vertical Honing machine with its unique self aligning mechanism, due to which concentricity & circularity can be maintained within 5 to 10 microns. This unique feature make this machine different from conventional horizontal honing machine. Our valued customers bear testimony to our competence with our two Gehring make — German machines.

Capacity : Jobs with bore diameter up to 1200 mm & length in excess of 8 meters, can easily be honed on our Vertical Honing machine.

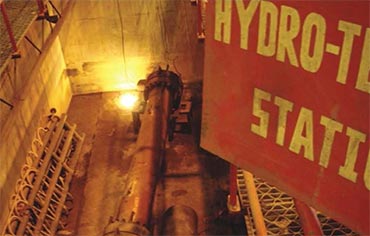

In Situ Machining

In situ machining facility available at United Van Der Horst can do face machining up to 1.5 meter diameter with the help of a pneumatic drive. API ring groove can also be repaired with help of this In situ machine. Successful jobs done are - Repair of Jacking system's Hub in/out board seating face for Trasnocean Offshore

Vertical Turret Lathe

Three number Jungenthal make German Vertical Turret Lathes to perform high accuracy machining such as turning and groove grinding. Jobs such as Main Engine Components like Piston Crown, Cylinder Cover, Oil Field equipments like Mud Pump module, API Spools and Flanges, Wind Mill )arts like King Pin, parts of Hydraulic Cylinders can easily be machined with good accuracy and surface finish.

Capacity : Diameters up to 1.5 meters and height up to 1.5 meters can be easily accommodated.

Groove Grinding

Description / Specification of Groove Grinding

We are involved in offering a wide range of Groove Grinding to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Groove Grinding. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Boring

Jungenthal Make, German Origin horizontal boring machine which can easily handle jobs like 2 meter diameter Bull Gear, Cyinder Heads in excess to 1000 mm bore dia., Nitrogen compressor cylinder bore up to 800mm dia., Rolling mill equipments like work roll and back-up roll chokes of size 1500 mm dia. are easily be machined on our boring machine.

Capacity : With its rotating table of 1 x 1 meter and with spindle of diameter 150mm we can machined jobs having horizontal travel up to 3 meters, vertical travel of up to 1.5 meters with weighing capacity of 15 T.

Chrome Plating

Van Der Horst —Holland due to their innovations in advance chrome plating technologies such as its patented "Porous Krome", set up its plant in India to cater customers in South Asia. United Van Der Horst has boost its excellence in porous and hard chrome plating for different diesel engine parts and various other components of hydraulics, with due considerations to environmental safety. Components are chrome plated with hardness up to 60-65 HRC and are super finish to achieve required surface finish value. Plating process followed by United Van Der Horst has been approved by American Bureau Society (ABS) and tested at NABL approved laboratory for Salt Bath Test, Chrome peel off test, Hardness Test.

Capacity : Jobs with maximum diameter of 1 meter and length in excess to 10meters can easily be chrome plated at our plant.

Demineralising

At United Van Der Horst everybody is more cautious about the quality, and to get the best results in chrome plating a good amount of investment made by the management as a result of innovative suggestion by Quality control department. De-mineralized water is used in chrome plating to reduce the contamination level of chronic solution.

Effluent Treatment Plant

Description / Specification of Effluent Treatment Plant

We are involved in offering a wide range of Effluent Treatment Plant to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Effluent Treatment Plant. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Submerged Arc Welding

Submerged Arc Welding (SAW) - With the help of 10 ton positioner, our welding expertise find it easy for welding over wide range of products like AGC cylinder, Work roll chock, Pinion - Shaft, Bevel Gears, Pinion, Piston, Piston Head and many more components with submerged arc welding process

Capacity : We can easily handle components in excess of 10 T for welding components of various types & shapes.

Welding

At United Van Der Horst, we got approved WPS (welding procedure specification) from third parties like ABS, DNV, IRS for the specific application & based on the material of composition which are tested at certified laboratory. Also our welders are 6G approved. Our welding capabilities cover the entire spectrum of welding - SMAW, SAW, TIG, MIG, etc. Our specialized welding like Aluminium Bronze cladding is approved by ABS - Houston. These processes are specifically for load / guide / bearing application and not to avoid scoring, wear & tear etc. for internal and external components such as exhaust valve spindle ad exhaust valve seat's damaged faces are weld build up using stellite weld material to provide hard and wear resistance surface. All the electrodes are baked at a temperature of 150°C to 200°C prior to welding to achieve sound welding.

Stress Relieving

Microprocessor controlled Electrical Stress relieving furnace ensures the right cooling and heating rate. It is equipped with two over head mounted heavy duty blower which ensures uniform temperature all around the furnace. With its mechanized door and trolley operations one can get the excess of job very easily.

Capacity : This can take jobs up to size of 8m3, (2mx2mx2m). The maximum achievable temperature is 900°C

Hydraulic Pressure Testing

With oil reservoir capacity of in excess of 1500 liters we can easily test all types of hydraulically operated cylinders up to pressure of 300 bar and more using self-made power pack. The filtration unit attached to the power pack enables in maintaining the NAS value less than 10 microns. For servo controlled equipments the NAS value will be maintained less than 5 before connecting the system with the equipment. The auto cycling facility present in our power-pack makes use to provide a smooth and jerk free operation for all hydraulically operated equipments.

Load Testing Pit

At United Van Der Horst we also provide load test of different hydraulic components at a pressure up to 600 bar on our load testing pit. Various type of hydraulic cylinders are been successfully load tested at pressure up to 600 bar as per the requirement of customer. The load testing process is carried out with all the safety needs

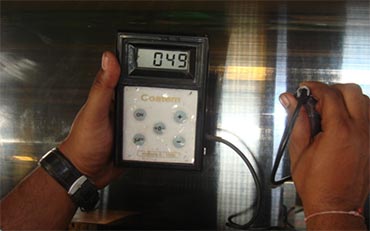

Ultrasonic Testing

The company has well equipped instruments for testing of incoming raw material as well as all the reconditioning or repair jobs for destructive, non-destructive and metallurgical testing. At United Van Der Horst we thoroughly test each and every components for any internal cracks or discontinuities using ultrasonic crack detector machine. Ultrasonic testing g is carried as per the procedure mentioned in ASME Section V.

Glass Bead Blasting Unit

Proven surface preparation techniques are available like, Vapour Blasting & Glass bead blasting to activate the chrome plated surface in the right manner to get the best bonding strength between the surfaces. Glass bead blasting machine is specially designed for complex geometry for which activation though conventional chrome eitch process is very difficult or not possible.

Capacity : This machine can easily accommodate job size of up to 500 mm diameter & length 1000mm.

Grit Bead Blasting

Grit blasting facility available at UNnited Van Der Horst can accommodate job of size in excess to 75 m3 (i.e. 5 mts x 5 mts x 3 mtrs Height) and weight in excess to 25 tonnes. Blasting area is well connected with all departments like plating, welding, assembly & dismantling section.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.