PROMAS ENGINEERS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PROMAS ENGINEERS P.LTD.

Planetary Mixers

Planetary mixers are an ideal mixer for the products of different viscosities, densities, shapes & proportions. The major uses include the production of latexes, dispersion & micro – dispersion of Chemicals, Explosive & agricultural pesticide formulations. It is suitable for mixing / blending powders as well as through mixing of ointments, creams, lotions, toothpastes, resins, slurries, ceramics, colors, pigments, rubber & other compounds.

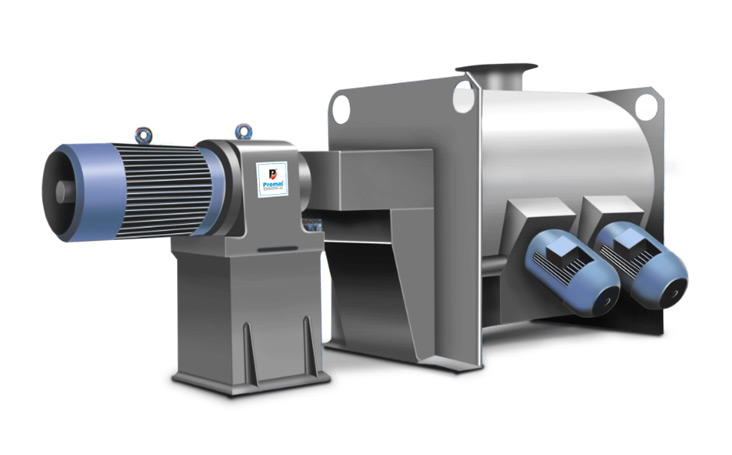

Sigma Mixer

The bowl is made of heavy steel plate making it a rugged heat proof unit. This is especially useful for bulky material and additional thinning prior to discharge. Tangential blades are supplied with differential speeds. Heavy duty machine cut spur gears are provided. Spherical type bearings are provided at both the ends to suit both radial and thrust load. Gland type shaft seals are fitted at both the ends for easy maintenance.

Ploughshare Mixers

This is a horizontal mixer consisting of a horizontal, cylindrical container enclosing plough shaped mixing elements mounted on a horizontal shaft.

The mixing effect is increased by separately driven, high speed rotating choppers or multiple choppers, which in cooperation with the plough shaped mixing elements, disperse the lumps and agglomerations or pasty additives with the powdery carriers. These Mixers can be provided with liquid feeding devices, jacket for heating / cooling, choice of seals, vacuum suitability for drying and varied material of construction (like mild-steel, stainless steel, Hastealloy, Monels) to suit the process materials. The Mixer is also provided with solvent recovery system.

Rapid Mixer Granulator

Rapid Mixer Granulator is an ideal mixer for pharmaceutical, chemicals and food products, including aqueous and solvent granulation, wax granulation, dry mixing and wet granulation. Promas Engineers is well known organization for manufacturer, supplier and exporter of rapid mixer granulator according to ISI guidelines and user’s requirements since 1990 from Mumbai to India and all over the world.

Working Principle Rapid Mixer Granulator

Spinning of material closed to the bottom of the mixing bowl and chopper blade sets the entire mixing in whirling and tumbling motion. Chopper blade assembly breaks the lumps formed during mixing. Different type of chopper blades provided for various applications.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.