Products & Services

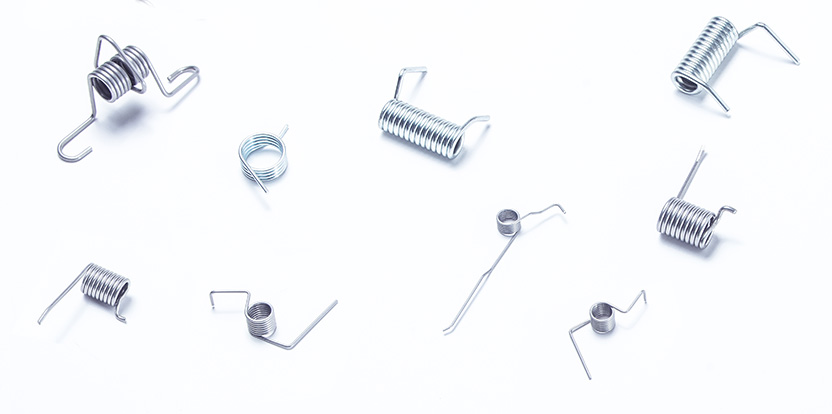

Torsion Springs

A Spring derives its usefulness by traveling to return to original shape when subjected to a load traveling around its axis. We offer a comprehensive range of torsion springs, which is available in various specifications. Widely used in several industrial applications, our range of torsion springs can also be provided in specific construction as per the requirements of our Customer.

Spring Clip Locking Clip Wireform Etc.

Wire forms have infinite uses and a wide variety of shapes and sizes. These forms can be a load bearing link with minimal deflection.

These clips are plenty in design & shapes. They are used for connecting two parts or for locking a sliding part.

These wire forms varying from simple to critical bendings along with different shapes to suit the fitment of end users.

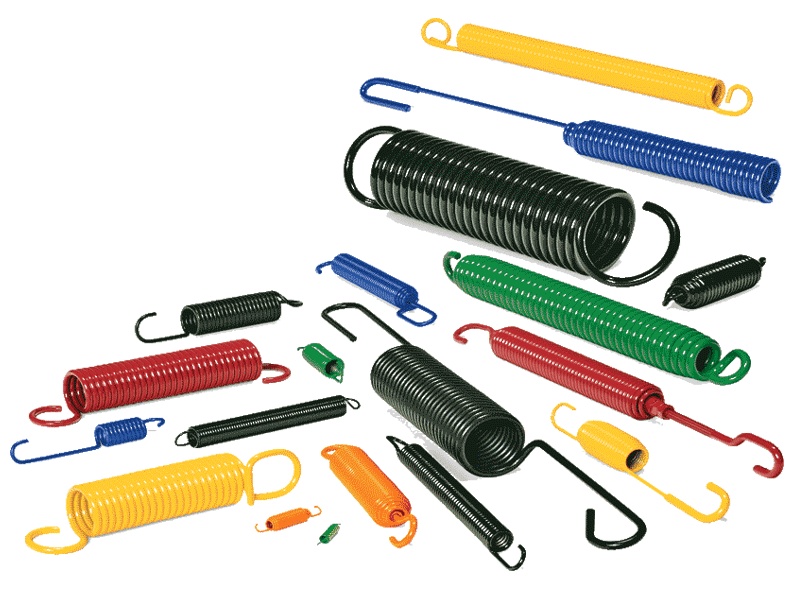

Spring Assemblies And Special Items

Considering the functional requirement, we assemble springs with various types of end parts, rods, locking devices etc. We also produce special items where spring action is required as per customer's requirement like critical shape, inadequate spacing, special kind of cross section of wire, etc.

Garter Spring

A garter spring is a hectically coiled steel spring that is connected at each end to create a circular shape, and is used in oil seals, shaft seals, belt-driven motors, and electrical connectors. Compression garter springs exert outward radial forces, while extension garter springs exert inward radial forces. The manufacturing process is not much different from the creation of regular coiled springs, with the addition of joining the ends together. Like most other springs, garter springs are typically manufactured with either carbon steel or stainless steel wire