PERFECT EQUIPMENTS P.LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PERFECT EQUIPMENTS P.LTD

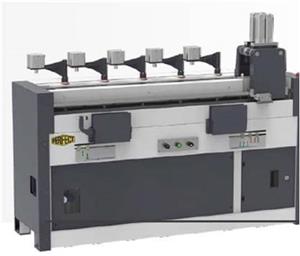

Flat Clipping Machine

Fully automatic PLC control machine

Pneumatic cylinders for all actions

No need for manual hammering for clipping at both ends

Ensuring safety, thanks to safetylight curtain

Quick and easy pre-programmable for different make of card’s flats

Carriage movement guides by LM guide for rigidity

Top pressing and clipping to the flat is simultaneous operation

ensures highest precision of clipping with respect to straightness of the flat bars

Also available for Rieter C-70 Card flat and Trutzchler TC 11 card flat, (PFC-4-60)

Motor 1.1 kw

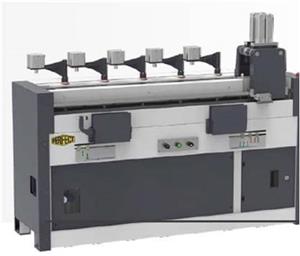

Flat Clipping Machine Pneumatic

All fully automatic PLC control machine Flat clamping unit, pre-bending and form rolling unit is pneumatically control.

No manual clipping is required at end of top.

Highest precision with respect to straightness of the flat bar in the clipping process.

Old Top Tear of attachment - for any one make of flat can be supplying with machine PFC-3

Flat End Milling Machine

For milling worn out flat ends, bring the original accuracy of Heel & Toe.

With fixed cam arrangement.

Novel arrangement of fix cam for accurate and easy Heel & Toe Milling.

Machine should be supplied with one pair of cam suitable for one make of card.

Control bar with supports and dial indicator.

The FEM-2 will mill flats types of 40” cards (60” version on request)

Two speed gear box to change RPM of cutter.

Clamping of flat by pneumatically operated clamp.

Pair of cam for any make of card.

Roller Mounting Machine

Suitable for mounting wire on rollers upto 1600 mm Length

Can be used to mount wire on Licker in, Feed Roller, Redirecting Roller, Stripping Fillet, Blow Room Beaters , etc

Traversing assembly with bearing guiding unit & wire Tension Indicator

Drive unit driven by A.C geared motor, Speed Control by Variable frequency Drive.

On Card Flat Grinding Roller

Save the time because flats from the machine need not to be removed.

Easy to install on card.

Drive-via motor assembly or via belt from card cylinder drive depending on the type of the machine.

Holding fixture to be provided by card manufacturer

The OCFG-1 will grinding flat from all types of 40” card (60” version on request).

Full width on Card Grinding Roller for Rieter C-60 Card, mounted with Ceramic Stones.

Also available for 40” Card.

Dressing bed for stone dressing of On Card Flat Grinder for Rieter C-60 Card

Automatic Cot Grinding Machine

Top roller removed from the Ring frame can be loaded directly into a trolley

Full trolley is directly docked into Grinding Machine & rollers are picked up for Ginding Automatically.

Automatic cot diameter measuring

Automatic sorting

Automatic grinding stone dressing

Similarly finished rollers are fed into a wating trollery. full Trollery can be undocked % taken to Ring Frame

Automatic grinding stone cleaning(optional)

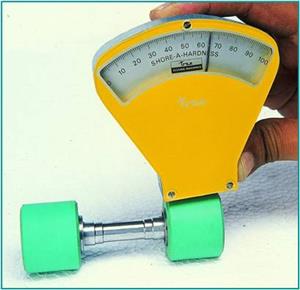

Cot Grinding Machine

Output up to 325-360 Top roller per hour.

Surface finish RA < 0.5 µmm.

Grinding accuracy 0.02mm.

Versatile grinding machine for highest grinding quality.

Efficiency of machine will be increase with auto feeding system.

Prevent accident.

Operator can attend to some other Job while the

Auto Feeding system will continue to feed the

arbour to grinding machine.

Auto Cot Grinder

Automatic cot grinding machine

Production of 250 arbours (500 Cits) per/Hr

Excellent surface finish,Ra < 0.5 mm

Two optionas for Grinding - Fixed cut or Fixed Diameter

Large Magazine capacity allowing machine to run for 1.6 hour (96 minutes) on its own

Touch screen controls, display & fault diagnosis

Power 4.86 kw

Horizontal Hydraulic Cot Mounting Machine

Description / Specification of Horizontal Hydraulic Cot Mounting Machine

We are involved in offering a wide range of Horizontal Hydraulic Cot Mounting Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Horizontal Hydraulic Cot Mounting Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Manual Cot Mounting Machine

Description / Specification of Manual Cot Mounting Machine

We are involved in offering a wide range of Manual Cot Mounting Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Manual Cot Mounting Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Ultraviolet Treatment Machine

This machine eliminate Acid treatment machine or other highly toxic chemical coating used for preventing lapping tendency on cots.

The machines can process all types of cots like Draw frame, Combers, Sliver lap Ribbon laps and all the variety of cots from Ring frames & Speed frames.

Spindle Lubricating Machine

With Three oil Tanks- For Topping Oil,Flushing Oil & Fresh oil.

Two Oiling Guns – For Bolster Flushing and Filling bolster with Fresh oil.

Fine filter for flushing oil

Flushing oil tank capacity: 23 Litre.

Topping oil tank capacity: 13 Litre.

Used oil tank capacity: 9 Litre.

Blow Room Machinery

Description / Specification of Blow Room Machinery

We are involved in offering a wide range of Blow Room Machinery to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Blow Room Machinery. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

New Generation Card

1000 SERIES NEW GENERATION CARD is result of experience gained from manufacturing & installation of more than 800 cards in about 110 textile plants, processing various kinds of raw material, meeting our customer’s expectations for Sliver Quality, Productivity & Efficiency.

PERFECT being market leader in Card Maintenance equipments has accumulated knowledge of over 35 years in working with all brands of cards. Close co-operation with many Textile Plants & guidance from Industry experts and understanding the criticality of close manufacturing tolerances to attain precise settings between various carding elements, were the guiding principles for the new 1000 Series card.

Our satisfied customers encouraged us to produce a card of contemporary design & features which meets their increased expectations.

We present to you PERFECT card 1000 Series which can match all available brands of cards for Carding PERFORMANCE, PRODUCTIVITY and EFFICIENCY and yet is available at AFFORDABLE price.

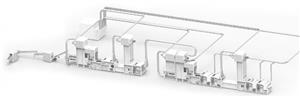

Cotton Waste Recycling Line

Raw material is expensive. Effort should be to maximise its use.

Yarn is traded as commodity, Increasing Price Competition.

Control on Raw Material cost is very important. Key to success for any industry.

In Textiles, nothing is waste. It can be used for some Purpose.

Try to recover as much fiber as possible from the waste generated during Spinning process and use it for some lower application.

Types of Textile Waste

Blow room Dropping

Card Licker-in Dropping

Card Flat Strip

Comber Noil

Pnuemafil Waste

Hard Waste

Fabric Waste

Used Garments

Assembly Winder

Description / Specification of Assembly Winder

We are involved in offering a wide range of Assembly Winder to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Assembly Winder. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Knitting Machine

Description / Specification of Knitting Machine

We are involved in offering a wide range of Knitting Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Knitting Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Auto Coner

Description / Specification of Auto Coner

We are involved in offering a wide range of Auto Coner to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Auto Coner. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Ring Frame

Description / Specification of Ring Frame

We are involved in offering a wide range of Ring Frame to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Ring Frame. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Two For One Twister

Description / Specification of Two For One Twister

We are involved in offering a wide range of Two For One Twister to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Two For One Twister. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.