NIRMALA PUMPS AND EQUIPMENTS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to NIRMALA PUMPS AND EQUIPMENTS

Aod 15 Pump

Specifications:

- Max Flow Rate: 23 Lpm (6gpm)

- 1/2" BSP (15mm) PP / PVDF

Port Size:

- Inlet: 12.70(1/2" BSP)

- Discharge: 12.70mm (1/2" BSP)

- Air Inlet: 6.35mm (1/4" BSP)

- Air Exhaust: 12.70mm (1/2" BSP)

Suction Lift:

- Dry: 1.45m (4.75') Wet: 2.83m (9.28')

Teflon:

- Dry: 0.50m (1.64')

- Wet: 0.90m (2.95')

- Max Particle Size (Dia.): 2mm (0.078")

Product also available in PVDF, ALUMINIUM & SS 316 material.

Aod 30 Pump

Specifications:

- Max Flow Rate: 135 Lpm (34gpm)

- 1" BSP (25mm) PP / PVDF

Port Size:

- Inlet: 25.40(1" BSP)

- Discharge: 25.40mm (1" BSP)

- Air Inlet: 9.53mm ( 3/8" BSP)

- Air Exhaust: 12.70mm (1/2" BSP)

Suction Lift:

- Dry: 3.05M (10') Wet: 4.89m (16')

Teflon:

- Dry: 2.14m (7')

- Wet: 3.98m (13')

- Max Particle Size (Dia.): 3.17mm (0.125")

Product also available in PVDF, ALUMINIUM & SS 316 material.

Aod 40 Pump

Specifications:

- Max Flow Rate: 270 Lpm (72gpm)

- 1½ " BSP (40mm) PP / PVDF

Port Size:

- Inlet: 38.10(1½ "" BSP)

- Discharge: 38.10(1½ " BSP)

- Air Inlet: 9.64mm ( 3/8" BSP)

- Air Exhaust: 12.70mm (½" BSP)

Suction Lift:

- Dry: 4.57mm ( 15') Wet: 7.62mm (25')

Teflon:

- Dry: 3.05mm( 10')

- Wet: 6.09mm (20')

- Max Particle Size (Dia.): 4.76mm (0.188")

Product also available in PVDF, ALUMINIUM & SS 316 material.

Aod 50 Pump

Specifications:

- Max Flow Rate: 586 Lpm (155gpm)

- 2" BSP (50mm) PP / PVDF

Port Size:

- Inlet: 50.80mm (2" BSP)

- Discharge: 50.80mm (2" BSP)

- Air Inlet: 12.70mm ( 3/8" BSP)

- Air Exhaust: 19.05mm ( 3/4" BSP)

Suction Lift:

- Dry: 4.57mm(15') Wet: 7.62mm (25')

Teflon:

- Dry: 3.05mm( 10')

- Wet: 6.09mm (20')

- Max Particle Size (Dia.): 6.35mm (0.250")

Product also available in PVDF, ALUMINIUM & SS 316 material.

P.P. Centrifugal Process Pumps

This Models Has high motor rating of 7.5kW has become a standard for vacuum ejectors for its Discharge head of 4 kg/cm².

- Size: 50mm X 40mm

- Best Efficiency Point: 20 m³/ 40 m.

- RPM: 2900.

- Flange Connection: ANSI B 16.5 Class 150 FF.

Features:

- No 1. Choice for process plants And Chemical Plants

- Natural's choice for pickling line in steel plants.

- PVDF Impeller Also available On Request.

Pvdf Centrifugal Process Pumps

The fluorinated polymers are widely appreciated for their remarkable chemical inertness and their excellent resistance to aging.

Polyvinylidene fluoride (PVDF) offer the specific advantages of ease processing in accordance with all the convention methods use in a plastic industry.PVDF; Polymerized, according to its own special process , offer a high degree of crystallinity to the that by other processes, resulting among other things in superior thermo-mechanical properties.

The intrinsic technical superiority is one of the reasons for the success of which PVDF has achieved on the world marker for more than 20 years. But nothing is possible without a genuine quality assurance policy which

Nirmala pumps & Equipments Follows with their efforts for total quality management over their products & services.

Mechanical Seals For Centrifugal Process Pumps

Seal Type 71 Mechanical Seals are Specially Designed for using Extremely Corrosive Duties. All Metal Components are including springs are Isolated from the Sealed, Aggressive Medium. These Seal Design Faces are moulded with Glass Filled PTFE with Highly Flexible PTFE Bellow. Simple checkout method function and cleaning possibility as this Mechanical Seal located easily accessible outside the pump.

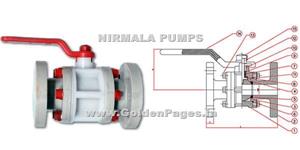

Ball Valve

- Valves are of three piece design, fitted with six set of metallic studs and nuts which contributes to their sturdy construction.

- Valves have full bore; thereby, allowing full 100% flow.

- Body and Stem seals are offered in various elastomers like EPDM, Neoprene, Hyplon, Butyl, and Viton and also in PTFE for chemical resistance against most chemicals.

- Valves with PTFE seals are provided with steel ring inserts which gives better sealing and safety features.

- Steel inserts in stem and handle give more strength, sturdiness, longer life and better performance.

- Carbon black resists ultraviolet rays and prevents degradation of polypropylene in sunlight exposure.

- Available in screwed end connections also.

Butterfly Valve

- Slips-in between line flanges, Wafer/Sandwich type, lug type, compact design , light in weight , easy to install.

- Elastomers seat provides bubble tight shut-off.

- Rigid body, sturdy construction, long trouble-free life.

- Ratchet lever mechanism permits locking of disc position determined by system requirement.

- Wetted parts only of PP/PVDF, HDPE/SS and elastomers compatible with fluid.

- Square section shaft provides positive engagement between shaft and disc, between shaft and lever ensuring positive shut-off with quarter turn operation.

- Suitable for flow in either direction, seals in both direction and can be installed in either vertical or horizontal lines.

- Available in screwed end connections also.

Diaphragm Valve

- One piece sturdy body with cross ribs to reinforce end flanges.

- Latest inverted design diaphragm remains unstressed while valve is in closed position give more service life.

- Deep seat allows maximum flow & excellent throttling characteristics.

- Available with Neoprene, EPDM, Hyplon, Butyl, Viton, Viton, Teflon-Coated and pure PTFE Diaphragms.

- Available in Screwed end Connections also.

Foot Valve

- Free Floating Ball Allows maximum flow through valve.

- The only moving part is the ball, so maintenance is reduced/nil.

- The solid polypropylene/PVDF ball seated on elastomers seat gives no chance for leakage.

- Ball fully supported by guide ribs for ful flow and maximum turbulence.

- Available with various elastomers seats like Neoprene, Hyplon, EPDM, and Viton for compatibility with different chemicals.

- Tight shut-off achieved at a minimum of 1 Meter water column.

- Available in screwed end connections also.

Nrv Valve

- Free Floating Ball Allows maximum flow through valve.

- The only moving part is the ball, so maintenance is reduced/nil.

- The solid polypropylene/PVDF ball seated on elastomers seat gives no chance for leakage.

- Ball fully supported by guide ribs for ful flow and maximum turbulence.

- Available with various elastomers seats like Neoprene, Hyplon, EPDM, Viton for compatibility with different chemicals.

- Tight shut-off achieved at a minimum of 1 Meter water.

- Available in screwed end connections also.

Sight Glass

- Three - piece design, sturdy construction.

- With full view various elastomers or PTFE seals to aggressive chemicals.

- Available in Screwed end connections also.

- Size range: 15mm to 150mm.

- Drilling: As per all internationally accepted standards, such as BS, DIN, ASA 150 etc.

- Hydrostatic Test: At 10 kg/Sq.cm.g for Body and Seat.

Moulded Basket Strainers

Manufacturer and Suppliers of Moulded Basket Strainer in PP.

Specifications:

Moulded Basket Strainer in PP in many corrosive or sensitive process media straining applications, plastic is the preferred material of construction for a basket strainer. Moulded basket strainers are resistant to wide variety of corrosive acids and other aggressive materials. They will work in applications that may require a much more expensive exotic alloy - if one were easily available. Their plastic constructions ensure that they will not contaminate sensitive process media such as photographic chemicals and de-ionized water.

Features

- Available in screwed as well as flanged connection.

- Hydraulically tested to 5 kg/cm².

- Excellent corrosion resistance.

- No process media contamination.

- Hand removable cover till size 4" (100 mm)

- In Line design.

- Optional threaded drain.

- No painting or coating required to survive a difficult environment.

Size Availability:

- 3/4", 1",1*1/2", 2",3",4" ,6",8",10".

Priming Chamber

Horizontal Pumps can be fitted with a Priming Chamber to provide self priming capabilities. Priming Chambers are Injection Moulded Polypropylene.

Priming Chamber is like a Tank which maintains Positive Head on the Pump. In case of Suction Lift applications, the Pump alone does not generate enough vacuum so that Pumping Liquid will rise from the Sump to the Pump Suction. Hence, a Priming Chamber is used which generates enough vacuum so that the Pumping Liquid rises and enters the Priming Chamber thus maintaining Positive Head on the Pump. Initially, for the first time, when the Pump is started, the Priming Chamber and the Suction Pipe must be Primed ( filled with Water ) this means that there is liquid in the Suction Pipe. Running of the Pump creates a vacuum thus, creating a volume deficit and the Liquid gets sucked in the Priming Chamber ensuring Liquid supply to the Pump. It is recommended that an NRV be installed in the Suction Line before the Priming Chamber so that the Volume contained in the Priming Chamber does not flow back to the Sump. Above all, a charge of Liquid necessary to prime the Pump is retained in the Priming Chamber.

Flange connection sizes available:

- 1" (25mm)

- 1.5" (40 mm)

- 2" (50 mm)

- 3" (75 mm)

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.