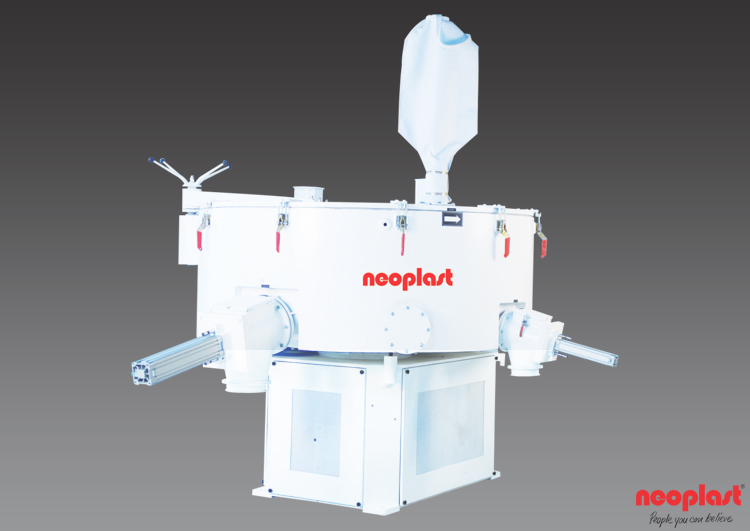

Cooler Mixer

Perfect height to dia ratio of Cooler Mixer vassel.

Precise Peripheral speed of mixing tool.

Least down time, so payback period is higher

Unmatched Pneuma seal / Capsule Technology.

Proper design of impeller.

Computerized balancing of rotating parts.

Best quality material of all key components of Cooler Mixers.

Unique design of bottom & discharge valve.

Very prompt after sales services.

Experience of manufacturing highest number of high speed mixers from the leading manufacturer and exporter in India.