MM AQUA TECHNOLOGIES LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MM AQUA TECHNOLOGIES LTD.

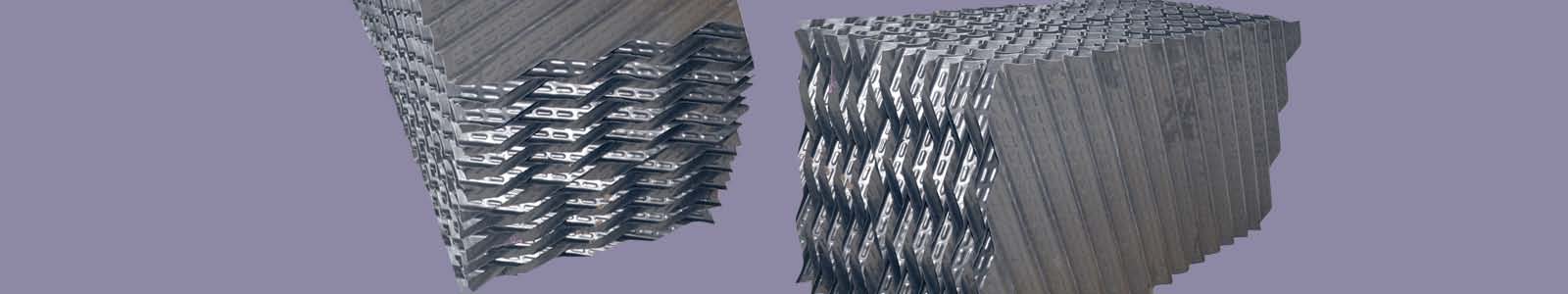

Tubedek

PVC tube settlers for solid liquid separation in water and wastewater treatment plants: Named as TUBEdek, it is a very high efficiency solid-liquid separator. This is due to the fact that its shape is hexagonal-chevron type that has got highest efficiency of separation among all other shapes available i.e. square, rectangular or hexagonal. Its area of application includes primary and secondary settling in water as well as wastewater treatment plants with any type of secondary treatment. It is also being very successfully used along with anaerobic digesters, to control the outflow of sludge and enhance gas production.

Traditional sedimentation tanks or clarifiers are large structures , occupying much valuable space , are perceived as high investment cost items.

Attacking the very crux of this problem, MM Aqua’s TUBEdek is a PVC tube settler which offers enhancing capacity for settling of suspended solids in a fractional area.

Using Munter’s technology, TUBEdek provides the most economical way of improving clarifier performance. Its major application areas are municipal, industrial and wastewater treatment. TUBEdek can be installed within settling tanks (both existing & new).

TUBEdek settling media helps to reduce the amount of suspended solids in carrier fluids ; thus improving effluent quality ; which in turn improves the efficiency of existing plants. Moreover, with TUBEdek, new clarification tanks can be designed in smaller size vice-versa maintain the same performance level, at less cost. The use of TUBEdek leads to the formation of large settling areas and small sink paths.

The TUBEdek model, FS 41.50 is easy to install in any shape of clarifier; its Hexagonal-Chevron shape is the most ideal for effective settling with or without coagulation or flocculation. High settling surface area (11 and 13m2/m3) leads to a very small clarifier size and the detention time requirement is also very low when compared to conventional clarifiers.

We have our structure framed keeping the Customer’s Interest in mind. We work on 3 L concept for economic solution and 3R concept for efficient solution.

3 L Concept:

Low Initial Capital Costs

Low Operating Costs

Low Energy Cost/Consumption

3 R Concept:

Reliable Performance

Resistance to Hydraulic and Organic Shock Loads

Robust construction

Features:

Increases the capacity of Clarifier

Increases the effective surface area of basin

Decreases the effective particle Settling distance drastically

It enhances the particle agglomeration and growth, bringing particles into closer contact with each other at the bottom of the tube

Unique hexagonal chevron configuration for superior settling applications

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.