Tantalum Bolt And Fastener

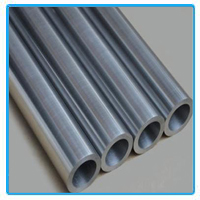

Tantalum Bolt & Fastener can provide custom tantalum fastener solutions for your unique tantalum bolt, tantalum nut & tantalum screw applications. Just let us know the requirements of your tantalum fasteners and our engineering staff will help guide you to the best solution for your tantalum fastener application.

Manhar Metal tantalum fasteners are optimized concerning chemical and mechical performance. Manhar Metal's fasteners offer the full corrosion resitance of Tantalum, but are mechanically improved due to their steel core and Tantaline's patented alloy bonding technology.Manhar Metal's tantalum fasteners offer a corrosion performance that is well beyond that of titanium or other Speciality metals like zirconium or Hastalloy.

Tantalum fasteners are also extremely stable at high temperatures, since its melting point around 3000C. Furthermore, tantalum fasteners are also one of the most bio-compatible metals around and because of is high density (16.68 g/cm3) its radio-opaque.

All tantalum fasteners are available in commercially pure tantalum, tantalum 2.5% tungsten (Ta-2.5%W) and tantalum 10% tungsten (Ta-10%W).

Physical Properties

Density 16.6 g/cc

Melting Point 3290 K, 2996°C, 5462°F

Boiling Point 5731 K, 6100°C, 9856°F

Coefficient of Thermal Expansion (20°C) 6.5 x 10(-6) / °C

Electrical Resistivity (20°C) 13.5 microhms-cm

Electrical Conductivity 13% IACS

Specific Heat .036 cal/g/°C