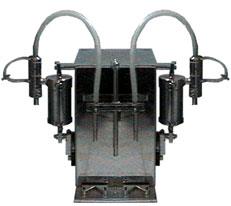

Automatic Filling Machine

A superiorly efficient range of Automatic Filling Machine exists with us. We are an exuberant manufacturer of high quality automatic filling machine. Minimum surveillance is required for our automatic filling machine. These robust automatic filling machines are obtainable from us on rock bottom rates.

Plc Based Filling System.

having Digital Volume and Weight

display. Therefore Quick Change

over for Different Volume.

39422.jpg)