Products & Services

Popular Tank Heater

The element has an open construction to allow free flow of liquid across the surface and to limit solid retention, which is particularly important when used in solutions which generate solid deposition such as Electroless Nickel and Copper plating processes.

The heater is thin enough to fit easily into confined spaces eg. behind anode baskets. The Popular can be supplied with hanging brackets for vertical mounting or standoffs for horizontal mounting. The integral Braudeflex lead has no junctions and is continuous and flexible.

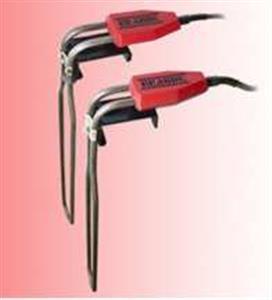

Cylindrical Tank Heater

The heater is small enough to fit in corners or recesses within the tank, out of the way of awkward workloads.

The Popular Cylindrical can be supplied with an optional adjustable hanging bracket for vertical mounting. The Braudeflex lead has no external joins and is continuous and flexible for ease of installation into new or existing plant.

Jet Stream

An externally mounted recirculation tank system designed for use where space in the tank is at a premium or the element needs protection from the workload. Jet Stream is fully non-corrodable and ideal for heated nitric and nitric acid/hydrofluoric acid mixtures, hydrochloric, sulphuric and chromic acids and most other known corrosive solutions.

It is a complete system comprising heating or cooling element, two pumps (one operational, one reserve) and controls, designed to occupy minimum floor space. Jet Stream can be used as an external system for process tanks or as an in line unit.

It is a complete system comprising heating or cooling element, two pumps (one operational, one reserve) and controls, designed to occupy minimum floor space. Jet Stream can be used as an external system for process tanks or as an in line unit.

Electro Jet

An external electric heating system fitted with Polaris electric elements which can utilise an existing recirculation and control system or be supplied complete with pumps and temperature control. The small footprint and compact design allows positioning alongside the process tank without occupying valuable space or intruding into work areas.

The height is 950mm and the diameter 400mm for the 9kW model and 632mm for the 18kW model.

The height is 950mm and the diameter 400mm for the 9kW model and 632mm for the 18kW model.

Thermaster Temperature Controller

Thermaster uses a PT100 sensor encased in Teflon for use in corrosive liquids which is provided complete with guide tube and flying lead for easy installation into your tank. Probe lengths are 0.5m as standard but can be made up to 8m. The controller is relay operated using a single set point and is accurate to =+/- 1oC. The enclosure is sealed to IP65

Thermaster O.T.P. Over Temperature Protection For Polaris Heaters

The OTP system consistes of a built in probe fitted to a Polaris heater which enables sensing of over temperature in the element. This is useful to protect plant in situations where there is no liquid in the tank and has been enthusiastically welcomed by engineers and insurance companies alike!

Tankmaster Temperature And Liquid Level Controller

Combined temperature and level controller suing Braude’s unique PT100 and conductance level probes compatible with the Thermaster and Levelmaster . There are a range of settable options such as high high temperature control and alarm functions. Enclosure to IP65

Self Priming Chemical Service Pump

The pumps provide operating heads up to 17m and suction lift up to 3.5m. A choice of three mechanical seals is available: Hastelloy C for general chemical service, stainless steel for less arduous applications or non-metallic seals for severe duties. Six motor sizes are available from 0.25kW to 1.5kW, all are rated to IP55.

All pumps are supplied with clear installation instructions, and Braude technical staff are always available to offer advice.

- Self priming chamber

- Lightweight and robust

- Operating temperature up to 100°C

- Corrosion and stain resistant

- High flow rate - up to 35m³/Hr

- High efficiency closed impeller

- Choice of mechanical seals to suit application

- Easy maintenance

- Leak proof union connections with adaptors available for existing BSP threads

All pumps are supplied with clear installation instructions, and Braude technical staff are always available to offer advice.

- Self priming chamber

- Lightweight and robust

- Operating temperature up to 100°C

- Corrosion and stain resistant

- High flow rate - up to 35m³/Hr

- High efficiency closed impeller

- Choice of mechanical seals to suit application

- Easy maintenance

- Leak proof union connections with adaptors available for existing BSP threads

Heavy Duty Pumps

For flow rates up to 22,000 litres / hr

A choice of mechanical seals is available: Non metallic for general chemical transfer, Double water flushed for electroless nickel plating or solutions containing solids and silicon carbide seats for solutions contaiing HF. Water regulating kits can be supplied fitted to the pump. Available in six electric motor sizes from 0.37kW to 1.5kW. ( 1 /2hp to 2hp), either single or three phase. Motors are rated to IP55.

- Body in PVDF, PVC or PP

- Handles solutions containing solids

- High temperature performance up to 100°C

- Corrosion & stain resistant

- High flow rate delivered at high head Flow rates up to 22m3 /hr

- Open non clogging impeller

- Choice of mechanical seals to suit application

- Double water flushed seal available

- Twelve months warranty

A choice of mechanical seals is available: Non metallic for general chemical transfer, Double water flushed for electroless nickel plating or solutions containing solids and silicon carbide seats for solutions contaiing HF. Water regulating kits can be supplied fitted to the pump. Available in six electric motor sizes from 0.37kW to 1.5kW. ( 1 /2hp to 2hp), either single or three phase. Motors are rated to IP55.

- Body in PVDF, PVC or PP

- Handles solutions containing solids

- High temperature performance up to 100°C

- Corrosion & stain resistant

- High flow rate delivered at high head Flow rates up to 22m3 /hr

- Open non clogging impeller

- Choice of mechanical seals to suit application

- Double water flushed seal available

- Twelve months warranty

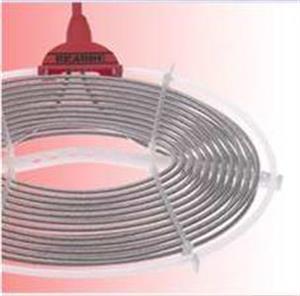

Heating Cables And Tapes

Electric heat by heating tape or heating cable

No matter if shop-terminated or cut to length our heating cables and heating tapes are suitable for frost protection as well as for process temperatures up to 1000°C and therefore meet the complex requirements of the heating technology.

No matter if shop-terminated or cut to length our heating cables and heating tapes are suitable for frost protection as well as for process temperatures up to 1000°C and therefore meet the complex requirements of the heating technology.

Liquid Flow Eductors

Braude Liquid Flow Eductors.

DESCRIPTION

Liquid flow eductors enable improvement of liquid flow and agitation in electroplating, pickling and cleaning tanks.

They function by taking liquid normally from a pump and because of their venturi design increase the flow rate by about 5 times.

All Braude eductors are manufactured in rugged PP as standard with other materials such as PVDF available to order.

Increase agitation

Directional flow

No aeration of liquid

Simple to install and use

DESCRIPTION

Liquid flow eductors enable improvement of liquid flow and agitation in electroplating, pickling and cleaning tanks.

They function by taking liquid normally from a pump and because of their venturi design increase the flow rate by about 5 times.

All Braude eductors are manufactured in rugged PP as standard with other materials such as PVDF available to order.

Increase agitation

Directional flow

No aeration of liquid

Simple to install and use