VIRAJ PROFILES LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to VIRAJ PROFILES LTD.

Stainless Steel Wire Rods And Wires

Stainless Steel Wire Rods:

This division is engaged in manufacturing of stainless steel wire rods and stainless steel wires. The quality of our product is well established in the international market. The SS Wire Rods manufactured in one division serve as raw material for our SS Wires plant. Our Wire rod division is well equipped with fully automatic wire rod mill from Siemens Italy & solution annealing, soft annealing & pickling plants with high end automation facilities & proven quality standards. Our manufacturing facility is capable of producing wire rod in extensive size ranges of 5.5 mm 39.5 mm.

Stainless Steel Fasteners

Viraj Profiles Ltd, is one of the leading manufacturers of stainless steel fasteners in India. Our Stainless Steel Fasteners division is specialized in the manufacturing of Austenitic grade of fasteners. Our Fasteners product range includes Hexagon head bolt, Hexagon head screw, Round head square neck bolt, Hexagon socket head cap screw in full thread and half thread, Hexagon wood screw, Hexagon socket button head screw, Hexagon socket counter sunk head cap screw in full thread and half thread, Hexagon socket button flange screw, square nuts, square weld nuts, hexagon weld nuts, thick nyloc nuts, hexagon flange bolts, threaded rods, dowel screws and many more. We provide products as per DIN, ANSI, JIS standards. Viraj has sophisticated, state-of-the-art manufacturing facilities for producing nothing but the best quality of stainless steel fasteners. Our backward integration allows us to produce the exact quality of fasteners, as required by the customers. Our stringent quality controls ensure flawless quality. Our fasteners product range consists of more than 20,000 SKU’s . Our customers span six continents and include the market leaders in every geography. Since its inception in 2006, the Viraj Stainless Steel Fastener division has become a world leader in the manufacturing of Stainless Steel Fasteners and is a reputed brand world wide.

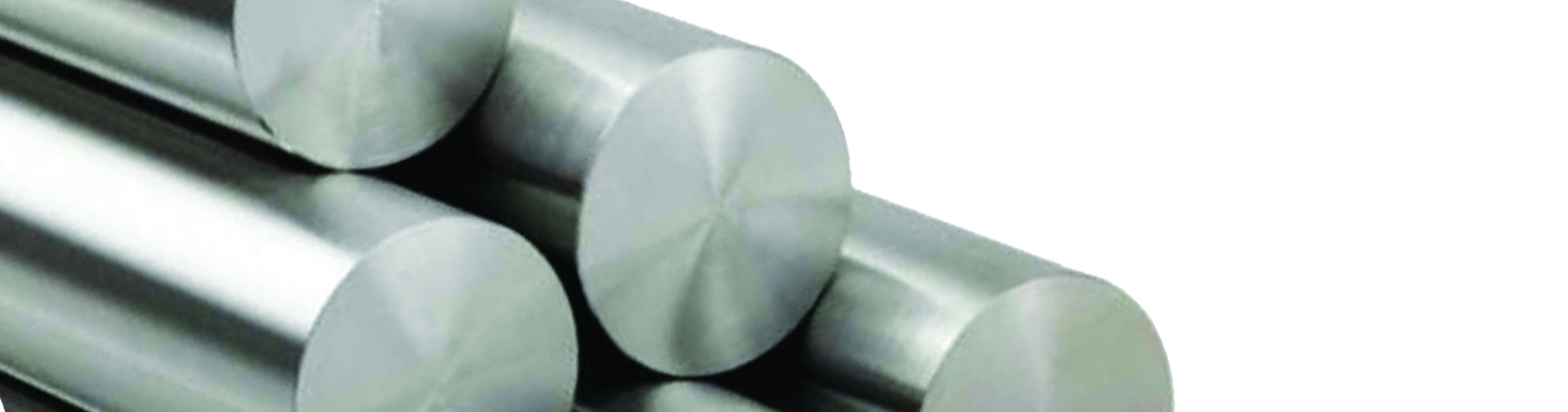

Stainless Steel Bright Bars

Our Stainless Steel Bright Bars division is engaged in the production and export of cold finished bright bars in the shape of Round, hexagon, square and flat in vast size range. We manufacture Stainless Steel bright bars in sizes ranging from diameter 3mm to 600 mm. Our Bright Bars manufacturing plant has integrated in house facility for heat treatment, (annealing, solution annealing, hardening and tempering), pickling, straightening, peeling, drawing, centreless grinding, polishing and buffing etc. This division high quality bars with the help of modern testing facilities like ultrasonic tester and eddy current tester for testing both the surface as well as internal defects. The quality of the products is well accepted by the consumers. This has resulted into an excellent business relation with the international market.

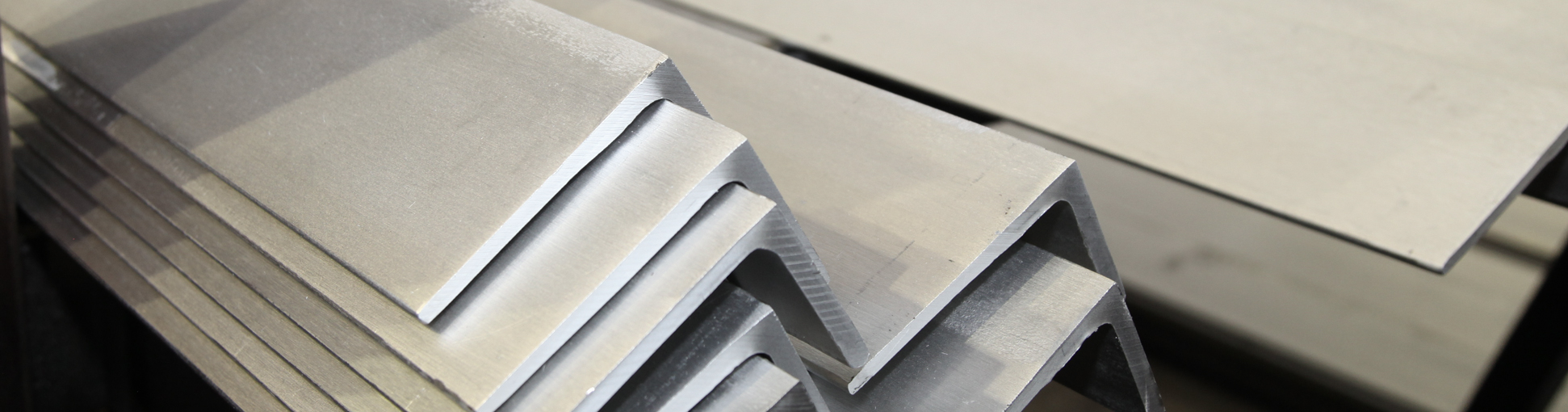

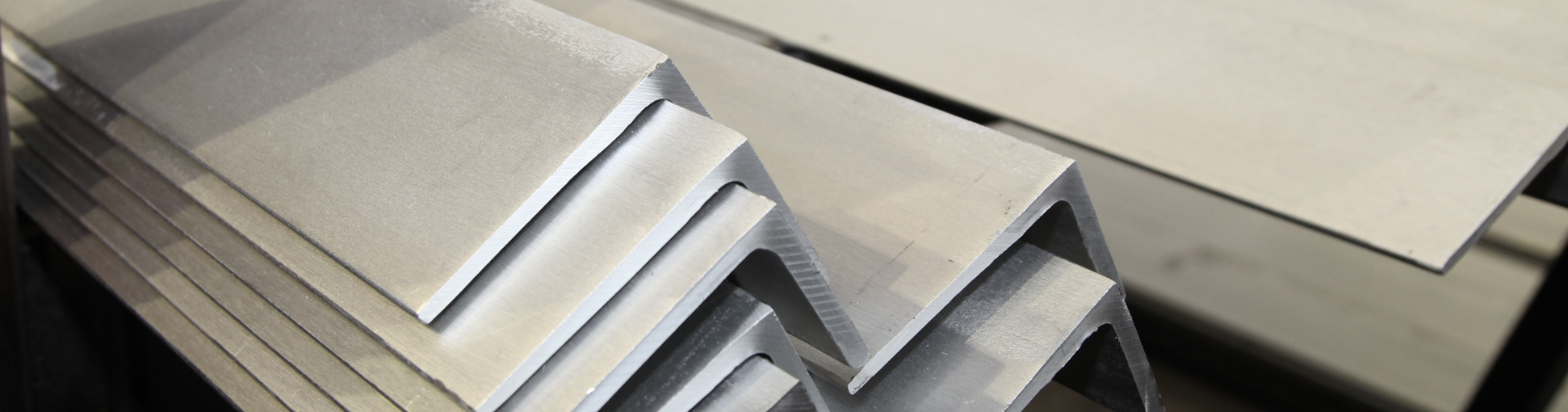

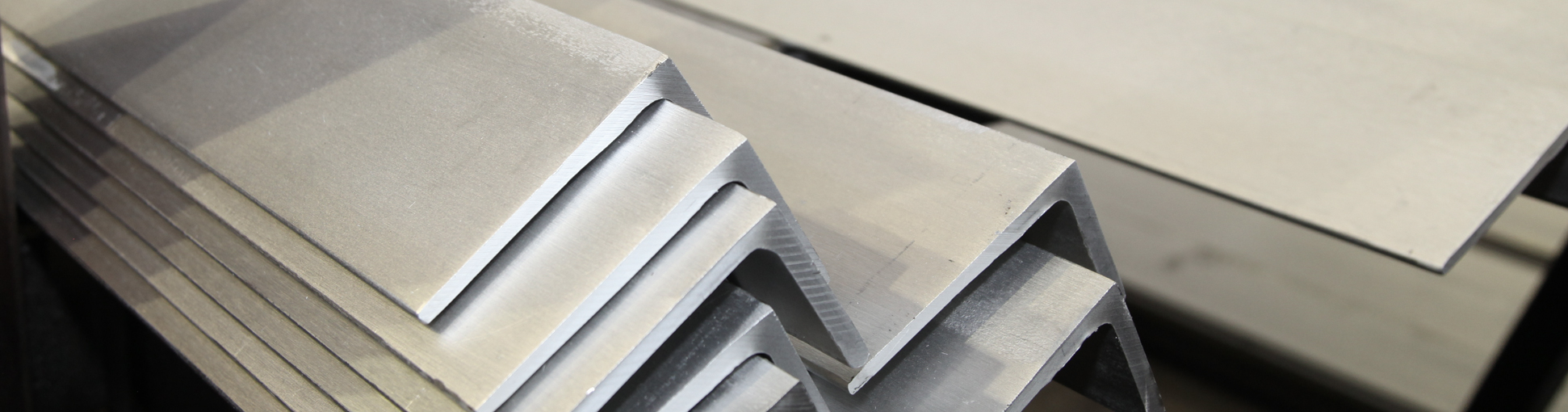

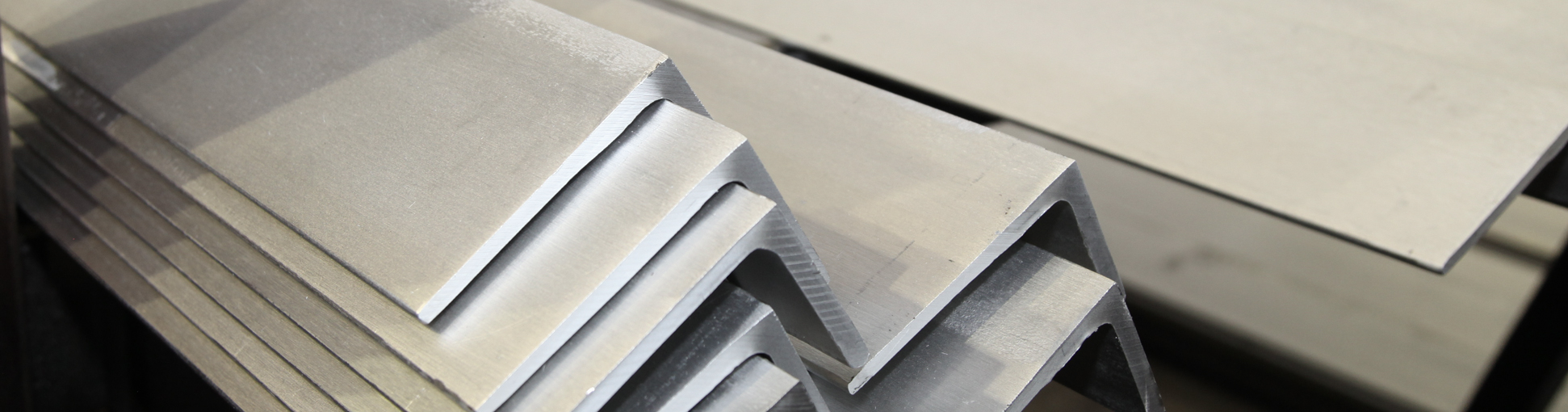

Stainless Steel Profiles

Viraj is a well-established supplier of stainless steel profiles for a large number of applications and industry segments. We have in-house facilities for complete process chain from the melting to the finished profile. By controlling the entire manufacturing process, Viraj ensures reliable supplies and a thorough quality assurance to its customers. Viraj Profiles division was established in the year 2000 and it quickly built up a reputation for the fast, efficient and reliable supply of the best quality stainless steel profiles and services.

Stainless Steel Welding Wires

Apart from the wide range of other products, Viraj manufactures Stainless Steel welding wire products also. The stainless steel welding wires include TIG, MIG, SAW, Core wires - coil form and core wire- cut length form for electrodes manufacturing. Viraj welding wires are used for welding purpose in Fabrication, Chemical industry ,Industrial food processing equipment, Pressure vessels, Automotive, Oil & Gas, Fertilizers, Railways, Ship building, Nuclear power projects and other various industries. These welding wires are approved by some of the reputed names of the industry like TUV( Pressure vessel), DB(German Railway), CE and ABS (Marine application). We manufacture stainless steel welding wire with brand name “Viraj”

Stainless Steel Flanges

At Viraj, we treat our customers as our partners by providing them with our products and solutions. And this ethos is displayed in not only our thoughts but also in our actions. Viraj manufactures Stainless Steel Flanges of different shapes and sizes and with different specifications as per the customers’ requirement. Viraj is the world leader in Stainless Steel Forged Flanges. We cater to the huge global demand of our customers who are spread across 6 continents and around 90 countries. Viraj flanges are reputed and well known across the globe for their reliability and quality.

Our flanges division encompasses an integrated forge shop which manufacturers all types of pipe fittings i.e. flanges, butt welding fittings in various specifications (ASME/ ANSI, EN, DIN, AFNOR, AWWA, GOST, BS, JIS, AS, MSS, SA, UNI ETC) as well as forged bars.

Grades

Description / Specification of Grades

We are involved in offering a wide range of Grades to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Grades. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Melting Shop

Our stainless steel melt shop encompasses five induction furnaces, three AOD converters with computerised Intelligent Refining System and two continuous billet / bloom casters.

Process Route:

Induction melting

AOD refining

Continuous / Ingot casting

Grades:

Austenitic: 201, 202, 204Cu, 301, 302, 302HQ, 303, 304, 304L, 304LS, 304H, 304HC, 304L Cu, 310, 310S, 314, 316, 316L, 316L Cu, 316H, 316Ti, 317L, 321, 347

Ferritic: 430, 430F, 434

Martensitic: 403, 410, 416, 420A, 420B, 420C, 431, 440C

Austenitic - ferritic (duplex): F51, F60, F68

Electrode: 304LER, ER307, ER307G7, ER 308L, 308 LER, ER 308LSi, ER 309, ER 309LSi, ER 310, 316LER, 316LSi, ER 347, ER 430, ER 420

Products:

Square Billet: 100 mm, 120 mm, 140 mm, 160 mm, 170 mm, 200 mm, 250 mm & 300 mm

Round Billet: 200 mm & 300 mm

Ingot: 13 inches x 17 inches, 16 inches x 20 inches & Polygonal Ingot of 7 Tons, 9 Tons & 12 Tons

Section Rolling Mill

TOMORROW’S TECHNOLOGY, TODAY - THE VIRAJ SRM PLANT

The new Section Rolling Mill (SRM), which is one-of-its-kind, was recently set up in Tarapur, Maharashtra. This state-of-the-art facility is a nation-first – being equipped with completely automated processes. There is no other industrial-scale unit of its ilk in the country.

What makes it so unique? Spread across 10 hectares, it boasts of some of the finest technology in the world’s stainless steel industry with its Level - 2 Automation processes. Its online pickling facilities, and automatic labelling inter-alia packaging line, amongst other features, will enable it to manufacture more than 700 different shapes and designs of angle, flats and other profiles. And it complies with the high environmental standards of modern stainless steel manufacturing.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.