TIJARIA POLY PIPES LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TIJARIA POLY PIPES LTD.

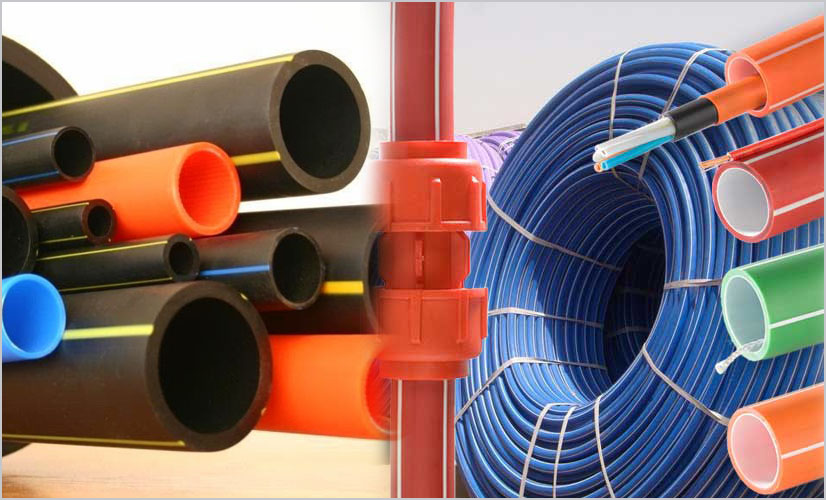

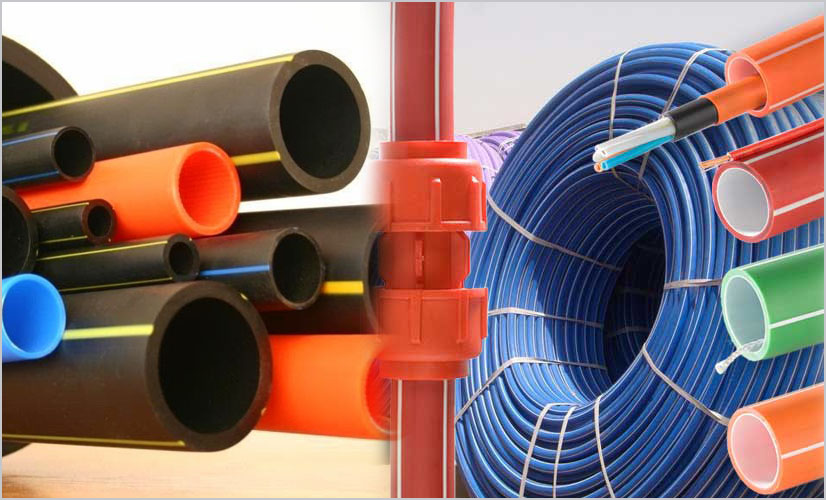

Hdpe Pipes And Coils

MATERIALS : It is made of either of three grades of High Density Poly Ethylene polymers. i.e PE-63, PE-80 or PE-100

PRODUCT RANGE : These HDPE pipes are available in sizes 20 mm to 500 mm in pressure rating of PN-2.5, PN-4.0, PN-6.0, PN-8.0, PN-10.0 , PN-12.5 & PN-16.0 in all three grades PE-63, PE-80 and PE-100.

APPLICATIONS : Effluent and Waste Water Disposal: Effluents of varied chemical compositions can be effectively disposed of using Tijaria / Vikas HDPE pipes & coils, with the aid of the latest know-how on piping engineering, pipelines for waste collection and disposal in chemical industry. Longevity of Tijaria / Vikas pipes under such application would rate the best amongst the conventional pipe even under critical service conditions.

Domestic Gas Distributions : Earlier, engineers always carried a psychological fear in using HDPE pipes rather plastic pipes for conveyance of inflammably gases. However experiments and extensive trials proved these fears totally wrong and have established excellence of performance of HDPE pipes for conveyance of all type of combustible gases. Experiments have also proved that the permeable losses are insignificant in regard to safety and environmental impact

Submarine Pipelines : One of the most important applications where all salient features of Tijaria / Vikas pipes prominently figure out is for under water pipelines. Tijaria / Vikas pipes have been successfully laid for under water river crossing, creek crossing, marine out-falls and for brine intake lines in the open sea. Hazardous chemical effluents and radio active wastes are being harmlessly disposed into deep sea through Tijaria / Vikas pipes with substantial cost savings. Schemes which would have been dropped due to economical un-viability have been made feasible with Tijaria / Vikas pipes.

PROPERTIES

Economical than traditional pipe material.

Resistance to chemicals- Exceptional resistance to all external and internal corrosion.

Resistant to electrolytic corrosion.

Will not rust or rot.

Very good thermal insulation due to low thermal conductivity.

Perfect stability of material obviates the risk of ageing.

Total neutrality to products conveyed.

Low maintenance cost.

Easy to install.

Longer life than G.I, M.S cement and other pipes.

Flame resistance classifying the material as self extinguishing according to test standard employed.

Welded joints speedup installation- Trench widths reduced which leads to saving in the cost of excavation and back filling.

Light weight - One sixth of the weight of steel. Low specific gravity giving an outstanding light weight product for easy transportation, handling, fitting etc.

Smooth bore provided less head loss. Flow resistance is approximately 30 % less than that of conventional pipes, permitting the use of a smaller bore pipe for a given rate of flow.

Plb Hdpe Ducts

CONSTRUCTION : PLB HDPE DuctsTijaria Permanently Lubricated HDPE Ducts are formed by co extrusion technique and are used for laying Optical Fiber Cables as under ground ducting / conduits.

MATERIAL : The base raw material being used for the manufacturing Permanently Lubricated Ducts is High Density Poly Ethylene. The grade of raw material is ultra violet grade and is confirming to IS:7328-1992 & IS : 2523 or ISO : 1183 & ISO : 1133 and is designated as PEELA-50T-012 (CACT Approved) and inner layer permanently lubricated material DOW CORNING grade-50MB002.

APPLICATIONS : Telecommunication, Computer Network, Automatic Signaling, Railways Information Network. Highways, Cable Service Providers, Broad Band networks, Electric cable installation etc.

PROPERTIES

Reduction of stress on cable during installation.

Installation of Longer lengths made feasible.

Negotiations of cable movement through bends and deflections are easier.

Reduction of number of joints and minimizes number of splices.

Faster and easy installation of cable with lesser man power.

Reduction of overall cost of installation, maintenance and future upgrades.

Retains it's properties throughout it's life.

Existing cables can be deployed after de-blowing from the duct.

This does not have toxic and dermatic hazards and is safe handling.

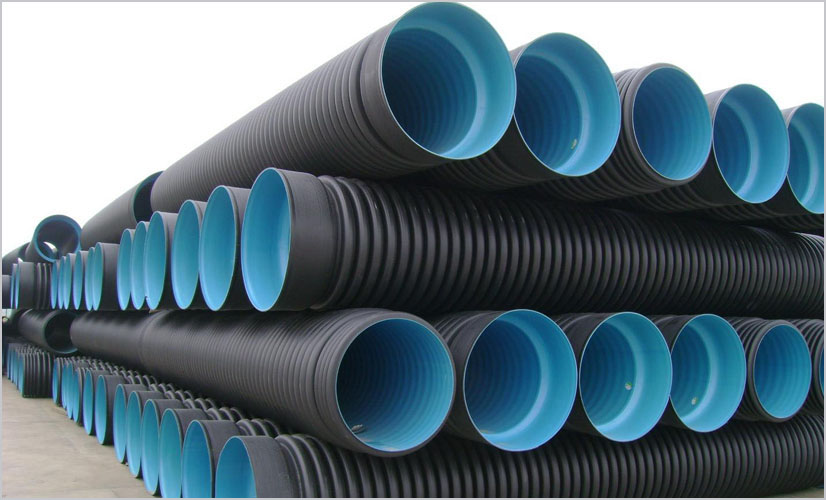

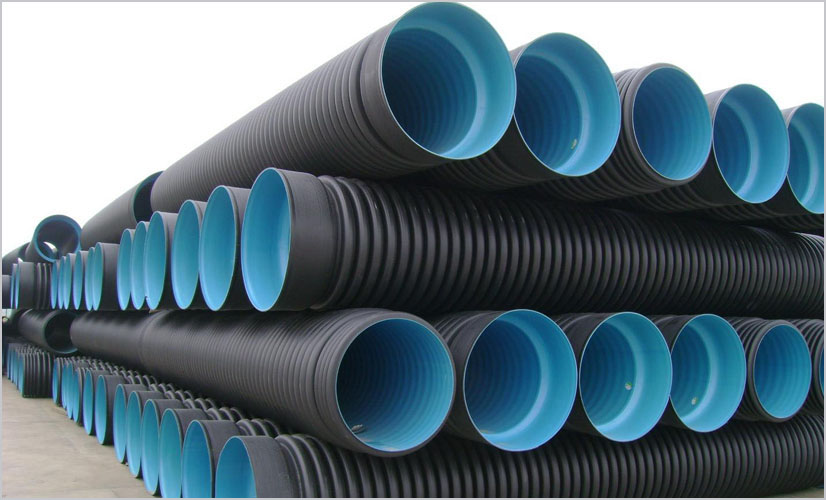

Hdpe Double Wall Corrugated Structured Wall Pipes

HDPE Structured-WallPlastics Piping Systems WithNon -Smooth ExternalSurface (Type-B) with hollow annular profiled outer surface & a smooth inner surface for Non- Pressure Underground Drainage and Sewerage .

MATERIAL : The base raw material being used for the manufacturing of Structured-Wall Plastics Piping System with non smooth external surface (Type-B) is Polyethylene (PE).

SPECIFICATION : The Structured -Wall Plastics Piping System & Fitting conforming to IS:16098 (Part-2): 2013 with latest amendment with or without integral socket and with elastomeric sealing ring joints (as per IS: 5328-2985) as wellas welded or fused joints.

PRODUCT RANGE : TIJARIA HDPE Structured -Wall Pipes with non smooth externalsurface (Type-B) are available in size from 75 mm to 500 mm inNominal ring stiffness (SN) class SN-4,SN-8 & SN-16.

APPLICATIONS :

Sewerage/Storm Water Drainage.

Effluents disposal & Industrial Drainage.

Highway & Busy Roads Drainage.

City & Urban clusters.

Sewerage Treatment Plants (STPs).

Urban Sewerage Rehabilitation.

Surface & Sub-Surface Drainage.

Storm/Flood Water I Waste Management & Culverts I Pavements drainage.

Drainage & Sewerage in Buildings I Housing Complex I Town Ships I Cantonments I Airport I Hospitals.

ADVANTAGES :

Due to its unique design,the pipes have following Advantages :

Maximum load bearing strength.

Available in different colors i.e Grey, Orange, Brown & Black on demand.

Chemica,l Corrosion resistant & highly resistant to abrasion.

Strong silt tight & water tight joints helps what stay inside the pipe, inside & what outside stay's outside.

HDPE corrugated pipe is light, tough and is manufactured in long lengths. This adds up to significant potential for installation cost savings.

PRODUCT INCORPORATED BY VARIOUS DEPARTMENTS:

Ministry of Urban Development.

County & Town Planners.

MP Urban Development Authority.

Military Engineering Services (MES).

Mumbai Municipal Corporation.

Maharashtra Jeevan Pradhikaran (MJP).

Maharashtra Housing Development Board (MAHADA) .

Naya Raipur Development Authority (NRDA).

National Highway Authority of India (NHAI- IRC).

Gujarat Water Suppyl and Sewerage Boards (GWSSB).

Rajasthan Urban Development Investment Program (RUDIP).

Delhi Jal Board (DJB).

Already being used by Major Township builder throughout the country .

Hdpe Sprinkler System

Agronomists all over the world believe that the sprinkler irrigation system is the best method to get maximum yield at an extremely low cost. Using sprinkler system can irrigate 2 to 3 time more farm land with same quantity of water. The sprinkler system cleans the surface of the plants, which help in easy photosynthesis thus making plants able to produce more. It save from irregularities of the weather.

In winters it saves from freezing of water. In summers it saves evaporation of water up to 40 %.

The Sprinkler effect (like rain)saves water from flowing away and maximum water reaches to the roots of the plants. It spreads water around the farm in equal quantity thus saving plants from bad effects of water clogging and water scarcity. With Sprinkler Irrigation System farming can be done easily on uneven surfaces.

CONSTRUCTION : HDPE High Density Poly Ethylene is the most popular variety of polymers. Tijaria / Vikas sprinkler pipe is made of HDPE plastic material. It is the recommended material for the manufacture of high pressure pipes and is renowned world wide for its reliability. The characteristics that makes it outstanding are its toughness, its resistance to chemical attack and its immunity to weather conditions. This makes it an excellent material to convey water.

PRODUCT RANGE : Tijaria / Vikas sprinkler pipes are available in 63 mm to 200 mm diameter and pressure rating class I, II, III, IV and Part I and part II. PN-2.5 and PN-3.2, PN-4.0, PN-6.0 with complete range of fittings.

Micro And Drip Irrigation System

MICRO / DRIP Irrigation System Tijaria Polypipes Ltd. introduces inline emitting pipe system for better irrigation of plants at very low cost and with scarce of water. This product confirms to Indian Standards as per IS:13488 & IS:12786. This is an integral pipe system (in-built) in which the emitters are inserted in the laterals during the extrusion process at preset distances.

Micro irrigation, also called drip irrigation or low-volume irrigation, delivers water directly to the root zone of the plant. There are many parts to a typical drip system, but a Micro irrigation system offers users the most value, including better control and water savings.

SALIENT FEATURES :

High clog resistant emitter designed with a unique wide turbulent flow path.

Large surface inlet screen orifice.

Two orifice outlets placed 180° apart at each dripper end.

The additional outlet reduces the suction hazard from sand particles when the laterals are drained.

Easy to roll and unroll during inter cultivating operations, thus reduces chances of mechanical damage without losing drippers.

Uniform emission rate along the lateral.

Available in wide range of emitter spacing from 20 to 150 cm as per customer's need.

INSTALLATION :

Quick and easy to install: Just unroll and lay the lateral to the reduce time and cost.

No need of punching the drippers on the lateral.

Can easily be connected to the PVC / HDPE pipe by means of head connector.

SPECIFICATIONS :

Manufactured in class 1,2,3,4 pressure ratings with different emission rates.

Operating Range :

Working pressure range: 0.7 kg/cm² to 2.25 kg/cm²

APPLICATION :

All field crops like sugarcane, cotton, strawberry, grapes, carnations, floriculture, banana, pineapple, vegetables, tea gardens, green houses etc.

Mdpe Pipes

Inherent characteristics of MDPE such as corrosion & crack resistant, tough and flexible makes Polyethylene piping systems the most preferred means for transportation and distribution of water, petrol and natural gases world wide.

MATERIAL :

The raw material used is Medium Density Poly Ethylene (MDPE). Tijaria / Vikas Pipes manufactures pipes in grades PE-80 & PE-100 for gas applications in sizes 20 mm to 450 mm (Outer Diameter) in all pressure ratings.

Traditionally these pipes are identified by its color for different uses like :

Blue - Water

Yellow - Gas

Orange - Petrol

SPECIFICATIONS :

Tijaria / Vikas Pipes manufactures MDPE pipes which confirms to national and International standards as ISO-4437, ISO-4427, IS-14885, BS-7281, DIN-8074/75. Tijaria / Vikas pipes can also be tailor made to meet the specific requirement of individual gas authorities or customers.

Upvc Rigid Pipes And Blue Casing

CONSTRUCTION :

It is made of Unplasticised Ploy Vinyl Chloride, Suspension grade, K value 65 - 67, a bulk polymer suitable for pressure pipes. uPVC has properties which allow it to be used as a replacement for and often advantage over traditional material such as Cast iron, Asbestos cement, Clay & wood.

PRODUCT RANGE :

Plain 20 mm to 315 mm.

Selfit 63 mm to 315 mm.

SALIENT FEATURES :

Strong and Durable

Light Weight

Length as required

Resistant to moisture, corrosion, chemicals, abrasion & wearing

Better flow characteristics

Leak Proof

Energy Saving

Safe

Convenient jointing

Termite proof and UV resistant

Longer lasting and maintenance free

Confirms to IS 4985 : 2000 in all respects.

Fittings :

Bend, Tee, Elbow, Coupler MTA, FTA, Service suddle, Reducers, End Caps etc.

Pvc U Underground Drainage And Sewerage Pipes

Tijaria manufactures unplasticised non- pressure Polyvinyl Chloride Pipes specifically to use in Underground Drainage & Sewerage Systems as per IS: 15328-2003 with latest amendments. These pipes are colour coded Brown & are available in plain as well as elastomeric sealing ring type and either use solvent cement or slide fit respectively for installation.

APPLICATION :

These pipes are designed to carry the soil & waste from the SWR Drainage Systems to appropriate drains or sewer through an underground network of pipes.

PRODUCT RANGE :

Tijaria/ Vikas Underground Drainage Pipes are available in sizes from 11Omm to 400mm ODin pressure rating SN-2, SN-4&SN-8.

SPECIFICATION :

Conforming to IS:15328-2003 with latest amendments with rubber ring joints as per ISO:4422 -1992 or DIN 8062 or IS:5382-1985 & with solvent cement joints as per IS:14182-1994.

Dimensions and Stiffness Class of

U-Drain pipes as per - IS 15328-2003 with latest amendments.

Swr Pipes And Fittings

CONSTRUCTION :

Tijaria / Vikas SWR Pipes & fittings are manufactured by compounding uPVC resin along with chemicals such as heat stabilizers, processing aids, lubricants, benzotriazole, phosphite based U.V stabilizers, pigments and carbon black UV stabilizers which noticeably improves the light stability of uPVC, prevents yellowing, imbritflement and loss of mechanical strength.

PRODUCT RANGE :

Selfit : These pipes have bell type socket at one end. Available in 40 to 160 mm sizes.

Ring-O-Socket : These pipes have ring type socket at one end. Available in 40mm to 160mm sizes.

ADVANTAGES :

Easy installation : Due to light in weight these pipes are easy to install and less time consuming than cast iron or Cement pipes. High Chemical Resistance: Highly resistant to acid, alkalies, cement, lime, oils and domestic affluents. Free Flow: Due to it's smooth inside surface any liquid flows very freely. Durable: These are strong and durable because of weather and sunlight resistant. These are also unaffected by termite, bacteria and fungus.

Pvc Electrical Conduit Pipes

Material :

It is made of PolyVinylChloride. The additives used in manufacturing this product having a quality of shock proof. We adopt high quality PVC Resin & imported processing aids with scientific formulas to produce pipes & fittings. Tijaria/Vikas PVC Electrical Conduit pipe conforms to IS:9537(Part-3)1983.

Salient Features :

For Commercial & Industrial Uses : Tijaria / Vikas PVC electrical conduit pipe has proven durable & effective for years of maintenance free performance in under-ground, encased & exposed application in accordance with the National Electrical Code.

Corrosion Proof : Resistance to most chemicals, PVC is not affected by any corrosion, Cement, lime, soils and salts.

Non magnetic & Non Galvanic : Merits of Tijaria/ Vikas PVC electrical conduits assure good insulation & no Power loss or conductor heading.

Self Extinguishing : PVC Merits make fire resistant qualities.

Impact Resistant : Tijaria / Vikas PVC electrical conduit is tough, durable & has high tensile strenght yet is easy to handle & install right on the job site.

Light Weight : Tijaria / Vikas PVC electrical conduit pipe is very light weight, high strength, long life span, low cost, lower cost of installation & lower transportation cost.

Cpvc Hot And Cold Water Piping System

Superior Performance

CPVC from Tijaria Polypipes Ltd. sets a tough new standard for performance in hot and cold water plumbing systems. With an advanced, new chemical formula, CPVC solves many of the problems of both copper and conventional CPVC, while delivering exceptional value.

CPVC is resistant to low-pH water, coastal salt air or corrosive soil. It also offers several other outstanding benefits:

Economical than traditional pipe material.

Full, unrestricted water flow.

Extremely cost-effective pricing.

Cement fusing.

Excellent heat retention.

Very quiet operation.

On the jobsite and on the job, Tijaria Polypipes offers builders and plumbers, the finest hot and cold water plumbing system on the market today.

Tougher Than Copper

Copper plumbing has been used for decades despite several inherent problems. It is subject to the corrosion and pitting caused by harsh water. It does not meet NSF Standard 6I. And it also exhibits low heat retention, condensation, noisy operation and susceptibility to damage during installation. Finally, its price is quite volatile. Vectus CPVC solves each and every one of these problems.

Tougher Than PEX

Cross-linked polyethylene (PEX) is a relative newcomer to plumbing applications and it offers many advantages. But many PEX products are something of a compromise. They vary widely in compound formulation, processing methods and performance. These problems are caused primarily by unreliable raw materials and production technologies. Many PEX products also suffer from varying materials, multiple standards, building-code questions, expensive tools and confusing repair-and-assembly methods. But that’s not all. Water flow may be restricted by insert fittings and tube I.D. Again, Vectus CPVC suffers none of these drawbacks.

More Impact Resistance - Fewer Installation Problems

Although conventional CPVC has a forty-year track record of reliable, trouble-free performance, it’s not perfect. It is susceptible to damage during the installation process, especially when sustaining an impact of approximately seventeen foot-pounds or more. And even though conventional CPVC has a very high burst pressure, it is also more brittle, which can also result in damage.

Unfortunately, this damage is usually not discovered until the piping is pressure tested at inspection. And that means unnecessary delays and frustration for contractors.

Enter CPVC. Fabricated using a new, state-of-the-art chemical formulation, CPVC offers exceptional performance for more trouble-free installation.

Simply put, CPVC offers greater durability to withstand the knocks and blows that piping is often subjected to in the field. Just as important, it cuts more cleanly in cold temperatures.

Polyester Partially Oriented Yarn

Polyester Partially Oriented Yarn, commonly known as Polyester POY is the primary form of Polyester yarn. It is also known as Polyester Pre-Oriented Yarn. It is the first form of yarn made directly by spinning Polyester PET Chips/Flakes. POY is mainly used in texturizing to make textured yarn, also known as Polyester Drawn Textured Yarn (DTY). POY can also be used in draw warping for weaving and warp knitting of fabrics.

POY yarn is available in different lustre like Semi-Dull POY and Bright POY. The Bright POY has the shine in it due to the cross-sections in the filaments. The fabric made from Bright POY also has the bright lustre. Polyester POY yarn is mainly available in Raw White color & is also available in various different colors.

POY is usually colored by the Dope Dyed technology as it is more efficient & the yarn gets evenly colored at each & every part. Color master-batch is mixed with the raw material to make the dope dyed POY. Dope dyed POY yarn can be used to make the Dope Dyed DTY yarn.

Polyester yarn is produced from PET Flakes, available in various types, used for producing belting fabrics, Polyester Zipper belts, polyester tyre cord fabrics, solid woven fabrics, hoses, conveyor belts, threads, ropes, lifting straps, engineering reinforcements, etc. Partially oriented yarn is made by winding the filament-receiving cylinder winds at a speed slightly higher than the speed of extrusion. Filaments from a large number of spinning positions are collected to form yarn, which can later be cut into staple. The diameter of Polyester yarn is designated by the term denier, which is the weight in grams of 9,000 meters of yarn.

In Tijaria, we are manufacturing POY yarn with 100% recycled ecofriendly PET Flakes. We have installed advanced Chinese machine based on German Technology.

As on today, Tijaria's total production capacity is 10050 MT POY per annum. Eventually, we intend to install 2 more lines of POY in order to increase the capacity by 2012.

Polyester Drawn Textured Yarn

Drawn Textured Yarn (DTY) is obtained when Polyester POY is simultaneously twisted & drawn. DTY yarn is mainly used in weaving & knitting of fabrics for making clothes, home furnishings, seat covers, bags and many other uses. DTY yarn can be in Semi Dull or Bright or Triloble Bright depending upon the type of sections of filaments.

Technical Properties of DTY yarn can be moulded in several ways to make the yarn suitable for its vast uses. Different heating techniques can be used to make the yarn set for specific use - 1 Heater DTY is normally woolly & more stretchable as compared to DTY with 2 Heater. Also the DTY yarn can be made with several combinations of Intermingle points - it can be Non-Intermingle (NIM) having 0 - 10 knots/meter or Semi-Intermingle (SIM) having 40 - 50 knots/meter or High-Intermingle (HIM) having 100 - 120 knots/meter.

These knots are not actually the knots tied when two threads are broken but they are the tangle knots created by heating pressure. These Intermingle yarns, also known as Interlaced yarn, are the replacement for lightly twisted yarns. Polyester DTY yarn can also be twisted to high twists like 1500 TPM or 4000 TPM (twist per meter). Such twisted yarn can also be heat-set to make the yarn permanently thermo-set the twist.

Polyester DTY yarn can also be obtained in various colors by the dope dyed technology or by conventional dyeing. Dope dyed DTY is usually packed on paper bobbins whereas Raw White DTY that will be used for dyeing is loosely packed on perforated plastic tube so that all the yarn can be easily dyed when the bobbin is dipped in color.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.