SUPER CHEMFAB ENGINEERS and CONSULTANTS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SUPER CHEMFAB ENGINEERS and CONSULTANTS

Underground Storage Tanks

We offer Underground Storage Tanks that are steel tanks, which are meant to control corrosion and leak protection. Our range includes single wall and double-wall steel tank consisting of a steel primary tank, which is enclosed within a 360° Fiberglass Reinforced Polyester Resin (FRP) that acts as a secondary containment tank. The steel inner tank provides structural strength and product compatibility while the FRP outer tank acts as a secondary containment by providing corrosion resistance. Further, we also provide coatings of tar as a cost effective means of anti corrosive coatings on the tanks.

Chemical And Acid Tanks

We offer a range of tanks suitable for storage of chemicals, strong acids, alkalis, oxidizing agents etc. According to the chemical/acid properties, storage specifications, truck mounted or stationary, vertical/horizontal, we design the tank in Mild Steel and Stainless Steel. Various types of linings are also offered by us for protecting the Tanks from corrosive nature of the Chemicals and Acids thus acting as foolproof solution for chemical storage in Fertilizer Industries, Chemical Industries, Power Plants, Transportation Tanks etc.

S.S Tanks For Milk And Water And Food And Acid

We manufacture Stainless Steel tanks of various grades 304, 304L, 316, 316 L etc. as per requirement of the customer and product needs. Food and Beverages Industry is one where Quality and Hygiene are the topmost concerns thus they are mostly stored in Stainless Steel Vessels as Stainless steel is Inert and doesn’t corrode too thus eliminating any possibility of contamination of the Food/Beverage. Such tanks are made for Storage of product in factories as well as for Transportation on trucks, in Horizontal and Vertical shapes as required

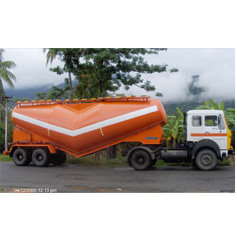

Cement And Fly Ash Tanks

We manufacture tanks used for storing and transporting Cement and Fly-Ash in plants. The design of these tanks is different from other tanks as the product is Dry Powder which doesn’t flow easily, that’s why the tank has a Conical bottom and the powder is pushed out by an Air Compressor. These tanks are mounted on trucks to transport Cement/Fly-ash to other industries where it is used as a product in their manufacturing process.

Silos And Bulk Storage

We manufacture Hoppers and Silos of varying sizes as per the storage requirement of the customer. These are used in construction sites, cement and fly-ash storage, agro food industries etc. for Bulk Storage of material and have Vertical orientation for easy discharge of the stored contents. Various bin bottom designs are available, again depending on the flow properties of the material and the desired silo withdrawal method. Single or multiple steel hoppers, flat bottoms and custom mass flow designs can be provided.

Rubber Lined Pipes And Fittings

We offer Pipelines for transporting liquids/gases from source to Endpoint/ Machines. According to the customer needs and the application of fluid, various sizes of Pipeline are offered by us with/without Flange system based upon Pressure and Flow rate of liquid. The Fluids are of corrosive and Non-corrosive nature thus we provide Anti-corrosive linings of varying thickness in the pipeline to prevent corrosion of pipes. Rubber Linings offered by us are:

Natural

Synthetic

Transportation Tanks

We offer a variety of Transportation Tanks which are used for carrying various liquids like Acids, Oil, Chemicals, Water on trailers/trucks. Our range consists of all kinds of standard as well as customized tanks to meet the requirements of the clients. We design, fabricate and install custom hazardous pressurized and non-pressurized tanks based on the customer’s needs since the contents have some degree of hazard associated with it.

It is recommended to take all the requisite precautions to make sure that the tank contents and the material surface of the tank do not react with each other. To provide complete protection to the tanks from corrosion or any other reaction we offer anti-corrosive linings of Rubber inside the tank surface or Epoxy painting.

Applications :

Rubber linings

Epoxy linings

Phenolic linings

Lead linings

Brick linings

FRP linings

Polyurethane linings

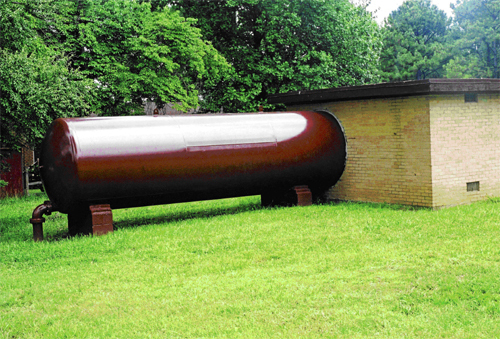

Hydropneumatic Tanks

We offer Horizontal type Hydropneumatic Tanks, which contain both water and air under pressure. The compressed air in the tanks acts as a cushion that can exert or absorb pressure as required. The air is absorbed into the water hence to replenish the air volume periodically a small air compressor may be used. These tanks help regulate proper system pressure range, both necessary for the efficient operation of a water supply system. They are widely used in large capacity pumping systems as “Buffer Tanks” and are also used in water systems and fire protection systems.

Shipping And Container Tanks

These tanks have Horizontal orientation and are used for transporting Oil, Chemicals, Acids on Ships as they are designed as per the shipping container size and specifications thus making them easily transportable by sea. The Tank is encased in a channel frame which gives support to the tank and the structure is such it is easily handled at the port by crane for loading and unloading of the tank. The Aesthetic design makes the tank look beautiful other than adding strength and handling possibilities to the tank.

Boiler Blowdown Tanks

Boiler Blowdown Tanks are used to control blowdown of a boiler so that the level of dissolved solids is minimized to reduce scaling in the boiler. These boiler blowdown tanks also enable high-pressure water to safely flash to steam. The amount of blowdown necessary depends on boiler operating pressure, amount of makeup water, impurity levels in the makeup water, and the dissolved solids concentrations that a given boiler can tolerate. The process of removing this water is referred as Boiler Blowdown.

As blowdown water has the same temperature and pressure as the boiler water, local laws usually do not permit this high temperature and pressure water to be discharged into the sewer. An acceptably designed blowdown tank system reduces the temperature by mixing cold water with the effluent.

Chlorine Tanks

We provide a wide variety of Chlorine Tanks that are used with chlorine injection system to comply with drinking water standards. They are useful as they are able to retain the water in order for it to be in contact with the chlorine added for disinfection. The tank is specially designed according to the working pressure of the existing or new water distribution system.

Lorry Tank

We offer a variety of Transportation Tanks which are used for carrying various liquids like Acids, Oil, Chemicals, Water, etc. on trailers/trucks. Our range consists of all kinds of standard as well as customized tanks to meet the requirements of the clients. We design, fabricate and install custom hazardous pressurized and non-pressurized tanks based on the customer’s needs since the contents have some degree of hazard associated with it.

It is recommended to take all the requisite precautions to make sure that the tank contents and the material surface of the tank do not react with each other. To provide complete protection to the tanks from corrosion or any other reaction we offer anti-corrosive linings of Rubber inside the tank surface or Epoxy painting.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.