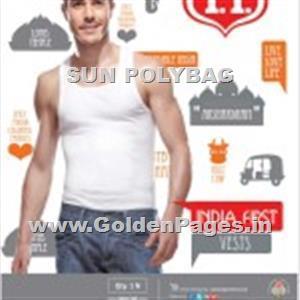

SUN POLYBAG P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SUN POLYBAG P LTD.

Bop.P. Bags

BENEFITS & FEATURES OF USING B.O.P.P. BAGS

1 – Laminated look to the product Shiny B.O.P.P. material used which influences buying motivation.

2 – Double sealing (optional) On sides to strengthen the B.O.P.P. Bags.

3 – Easy re-usable Tape To handle easily for repeat use.

4 – Economical To Duplex, PVC or other packaging.

5 – New concept Innovative & attractive packaging which has customer appeal.

6 – Convenient packaging Lesser number of processes involved so time saving.

7 – Excellent Printability Perfection to give better look to the product.

8 – Hanging Facility For better display & visibility at outlet.

9 – Eco Friendly Recyclable.

10 – Dimensions – Starting from 2″ wide x 55″ tall.

11 – Styles – Available in tubular (seamless) or back seam form.

12 – Printing – Up to 8 colors.

13 – Top – Open top, with or without handle, easy open.

14 – Bottom – Closed bottom. (Image below on left)

15 – Surface of the bag Laminated shinny prints.

16 – Added features Includes easy carry handle, gusseted, open mouth, Easy open strip and more.

Laminated Non Woven Carry Bags

Laminated Non woven Fabric is made of spun bond which can be recycled, naturally decompose and completely incinerates without any production of poisonous pollutant. Even though the bags look like a textile, they are in fact made from spun. No water is used in the production process and thereby not polluted. The material is recyclable thus environmentally friendly & assists with environment protection.

Laminated Non woven carry bags carries lots of useful properties like:

Strong

Durable

Cushioning

Softness

Liquid Repellent

Air permeability (Dehumidifying Factors)

Non allergies to human bodies

Eco-Friendly

Reusable

It is easily customizable.

Laminated Non Woven Bags are the most popular eco friendly bag because of their low cost, durability, and customability. These bags are made from hundred percent recyclable and reusable polypropylene material.We produce laminated non woven bags ourselves.

Laminated Jackets Zipper Bags

Our company is deemed as one of the leading manufacturers, suppliers and exporters of Exhaustion Laminated Nonwoven Bag. In order to meet the international quality standards, we assure to use premium quality material and yarns in the manufacturing process of this fabric. To ensure flawless finish, this fabric is duly checked on various parameters like strength and neat stitching. This fabric is ideal for making bags and other industrial applications. We assure to deliver this Exhaustion Laminated Nonwoven Bag in suitable packaging material to ensure safe shipment.

Features:

• Fine finish

• High tearing strength

• Long lasting nature

• Vibrant colors

Jacket Interlining is a unique product of our company. It is used to make high-quality jackets. It is used by leading jacket manufacturing companies.

Features:

• Made of high-quality materials

• 100% safe for skin

• Available in size as per client’s requirement.

Non Woven Bags

Non Woven Bags – Carry Bags

Non woven Fabric is made of spun bond which can be recycled, naturally decompose and completely incinerates without any production of poisonous pollutant. Even though the bags look like a textile, they are in fact made from spun. No water is used in the production process and thereby not polluted. The material is recyclable thus environmentally friendly & assists with environment protection.

Non woven carry bags carries lots of useful properties like:

Strong

Durable

Cushioning

Softness

Liquid Repellent

Air permeability (Dehumidifying Factors)

Non allergies to human bodies

Eco-Friendly

Reusable

It is easily customizable.

Non Woven Bags are the most popular eco friendly bag because of their low cost, durability, and customability. These bags are made from hundred percent recyclable and reusable polypropylene material.We produce non woven bags ourselves.

Non woven polypropylene is a practical fabric because it is strong and extremely lightweight, so it is convenient to carry as well as inexpensive to ship. The fabric is also comfortable and soft.

Polyester Laminate Bags

Strength, durability, cost, and stretch make polyester material the most widely used in fabric structures. Polyesters that are laminated or coated with PVC films are usually the least expensive option for longer-term fabrications.

Laminates generally consist of vinyl films over woven or knitted polyester meshes (called scrims or substrates), while vinyl-coated polyesters usually have a high-count, high-tensile base fabric coated with a bondable substance that provides extra strength. Precontraint fabric is made by placing the polyester fabric under tension both before and during the coating process. This results in a weave that has increased dimensional stability.

Classic Bags

Our brand is registered as BLUE ICE.

“AT BLUE ICE, WE PROVIDE HIGH QUALITY STORAGE BAGS WHICH CAN BE USED IN WEDDING, HOME USE , GIFT PACKS AND OCCASIONS.

KEEP YOUR CLOTHES SAFE IN ALL SEASONS. PURPOSE FOR USE : • SAREES • SUITS • SHIRTS & T-SHIRTS • JEANS & TROUSERS • KIDS CLOTHES • WOOLLEN CLOTHES • ALL TYPES OF CLOTHES”

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.