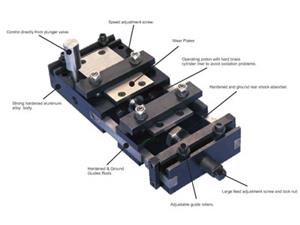

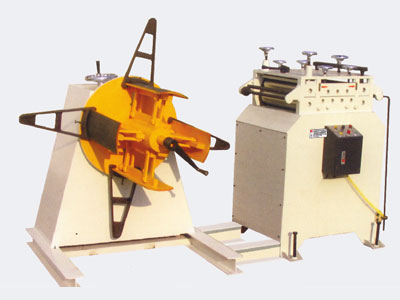

Gear Change Feeders

We are a renowned manufacturer, exporter & supplier of High Speed Gear Change Feeders. These products have cam mechanism, high precision feeding, speed up to 40m/min & one year quality guarantee. Cam option is 3, 4, 8, 12 division, feeding length is chosen according to the cam division and gear ration and they are suitable for numerous productions. Our feeders can be availed by customers at reasonable prices.