STORES SUPPLY INDIA AGENCY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to STORES SUPPLY INDIA AGENCY

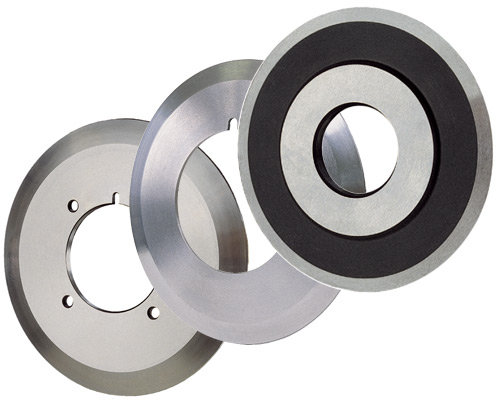

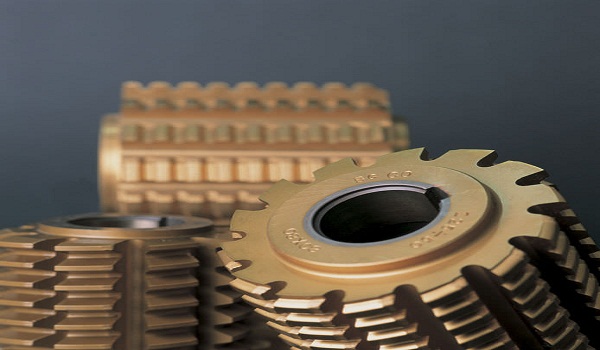

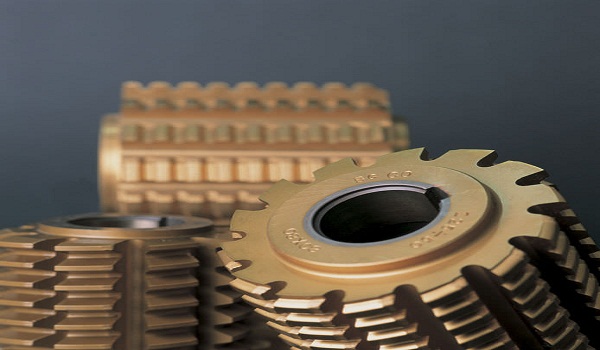

High Speed Steel

Modern industrial production, in particular mass production, machining is one of the most important shaping and forming processes. Almost all tools employed for this purpose are made from high speed steels. In recent times, the use of high speed steels has gained increasing importance for chipless shaping, e.g. for extrusion, blanking and punching tools. With regard to chemical composition, a clear distinction is made between 'Tungsten', 'Molybdenum' and 'Tungsten-Molybdenum' alloyed high speed steel grades which, depending on the dominant stresses they will be exposed to, contain differing amounts of Carbon, Vanadium and Cobalt. The characteristic properties of all high speed steel grades include:

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.