KRYSTAL SURFACE SOLUTION

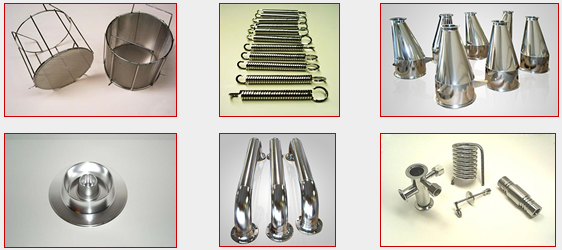

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KRYSTAL SURFACE SOLUTION

E Polish 250 Of Stainless Steel

E-Polish 250 is essentially the reverse electrolysis process by which a metal is removed from a work piece by passing appropriate electric current while the work is dipped in a specially-formulated solution. In an E-Polish 250 system, the work piece is dissolved by adding metal ions to the solution thus removing flaws from the surface of the metal part.

E-Polish 250 is a precision controlled electrochemical elimination of the surface metal, ensuing vivid “mirror like” look with enhanced chromium enriched metallurgical surface properties. Referred as “reverse plating”, this process has a levelling effect producing smoothness and enhanced reflectivity. Most significantly, the distorted, vague surface layer of the metal is removed off, thus leaving a chromium-rich, passive surface free of embedded contaminants like iron and work-inducted residual stresses from machining and forming. This procedure is safe and does not cause etching and pitting under controlled situations. E-Polish 250 will eliminate hydrogen from the surface limiting the bacteria growth.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

49353.jpg)