CAPITAL ENGINEERING CORPORATION

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CAPITAL ENGINEERING CORPORATION

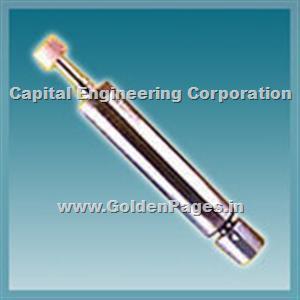

High Frequency Grinding Spindles

CAPITAL's Motorized Grinding Spindles

Capital is manufacturing precision motorized spindles for over 15 years. We emphasis on quality, accuracy and on time delivery which makes Capital's Spindles the best choice for your production needs.

We specialize in precision fitting custom built AC Induction motors to the spindle shaft. Precision balancing of these units provides high accuracy and high-speed capability. A temperature controlled assembly and inspection area and state-of-the-art coordinate measuring machines.

Horsepower Heat Dissipation

Motor horsepower (HP) is a function of the size and the RPM of the motor. The larger the motor, the greater the horsepower at a given RPM.

Motors that generate greater heat loss can be cooled with a fan that blows air over the motor. These motors are classified TEFC (totally enclosed fan-cooled.) When even greater horsepower is required in a smaller package, TELC (totally enclosed liquid-cooled) motors are used. These motors are cooled by circulating liquid around the motor.

Capital has many years of experience in the design and application of precision motorized spindles. For more information you may please contact

Variable Frequency Drives

Capital supplies motorized spindles for any speed up to 75,000 RPM. To operate at speeds other than 900, 1200, 1800 or 3600 RPM, a variable frequency drive is required. Variable frequency drives must be carefully matched to the motors they drive. Motors and variable frequency drives have pre-determined volts-to-hertz ratios, and these ratios must match for a successful application. Speed control can be integrated into your machine control for ramp-up, ramp-down and adjustment. This can be included in your machine program code or as an electrical control switch or dial

Spindle Lubrication

High speed spindles require special bearing lubrication. Capital’s air/oil lubrication systems injects precise amounts of oil at controlled intervals for optimal bearing life and minimum heat generation. Utilizing only fractions of a drop per cycle means no environmental oil mist concerns. In addition the high air pressures used provide maximum protection against contamination of the spindle.

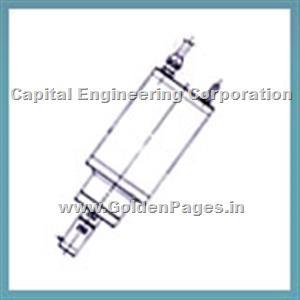

Surface Grinding Spindles

As the name suggest, Surface Grinding Spindles are designed for surface grinding. These grinding spindles are especially fabricated for some special applications. They can be categorized as high frequency driven grinding spindle, motorized grinding spindle or belt driven grinding spindle.

Usage:

These are suitable for surface grinding machines, and special applications.

Designs Available:

Spindles can be manufactured as per the customer's requirement.

Features:

These spindles are manufactured with integrated 3 phase motor upto 40 H.P.

High Frequency Internal Grinding Spindles

We are manufacturers, suppliers and exporters of High Frequency Spindles. They are used as Internal Grinding Spindles. These spindles are specially designed for grinding. Grinding Spindles are used in any machine for high productivity and surface finishing. These grinding spindles are made of stainless steel alloy.

Usage of Capitals Hi-Frequency Spindles :

Capitals Hi-Frequency Spindles are used for internal grinding applications, where high speed and high accuracy is required. We claim our Spindles accuracy within 2 Microns. Hi-Frequency spindles are also helpful in getting high productivity and better surface finish. Capitals Hi-Frequency Spindles have Integrated motor design which eliminates gears and pulleys, and thus make it, compact.

All the rotating parts are dynamically balanced and tested with latest measuring equipments to get vibration free performance.

Main Advantages of Using Capital's Hi-Frequency Spindles are:

Increased part output

Improved surface finish

Integrated motor design eliminating gears and pulleys

Compact design

High torque and high power values

High rotational speed

Very high axial and radial stiffness values

High metal removal rates

Angular position and speed control sensors

Automatic Tool Change systems

Temperature sensors

Accelerometers, Ability to interface to a wide number of drives and frequency converters

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.