Concrete Truck Mixers

Quality for all requirements

Stetter truck mixers are the result of experience gained over decades accompanied by permanent advancement and optimization. They incorporate the know-how from a production of more than 60,000 truck mixers which have proved to be reliable concrete mixer all over the world. Stetter truck mixers are characterized by low-maintenance technology in a modern design, simple handling, cost minimizing in maintenance and service, efficiency and excellent cost effectiveness.

Mature Technology in Functional design

With Stetter truck mixers of the C and N version, the time spent on filling, discharging and cleaning is reduced to a minimum,thus you save time and money. Stetter truck mixers are available with mechanical or electronic control unit. Reliable drive components guarantee smooth operation. The truck mixers are available with a nominal volume of 6 to 10 m3 with slave engine or PTO driven.High Loading volume thanks to high water line Optimum drive characteristics thanks to a low center of gravity of the mixer Wear-resistant plates in feed hopper, discharge shell and swivel chute 5 mm mixing spirals in the main wear zones Stetter T-protect wear protection (30 x 8 mm) on the mixing spirals

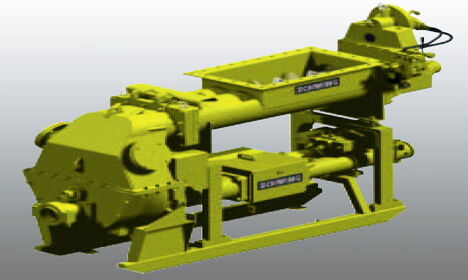

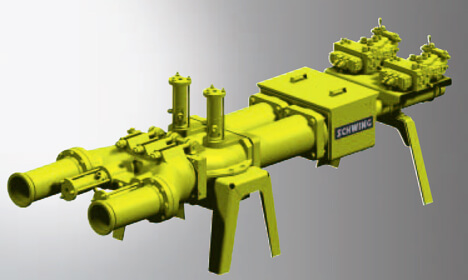

Trailer Line

Truck mixer body and semi-trailer have been optimally coordinated to form compact units guaranteeing a high loading volume, high payloads and optimum driving characteristics thanks to a low center of gravity. Stetter truck mixers of the Trailer Line are built in modular construction and can therefore be optimally adapted to the individual tractor unit. The semi-trailers are available as 2 or 3 axle versions with 9 or 10 tons technically permissible axle loads. They are state of the ar t and have features such as axles retarded by disc-brakes and ABS, EBS system, air suspension. Road stability system (RSS) upon request.

The truck mixers are available with a nominal volume of 10 m3