SANDEEP ENGINEERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SANDEEP ENGINEERS

Fabrication Panel

It is a mechanical device used to facilitate heat exchange from water to a refrigerant in a closed loop system. The refrigerant is then pumped to a location where the waste heat is transferred to the atmosphere.

In hydroponics, pumps, lights and ambient heat can warm the reservoir water temperatures, leading to plant root and health problems. For ideal plant health, a chiller can be used to lower the water temperature below ambient level; 68°F (20°C) is a good temperature for most plants. This results in healthy root production and efficient absorption of nutrients.

In air conditioning, chilled water is often used to cool a building’s air and equipment, especially in situations where many individual rooms must be controlled separately, such as a hotel. A chiller lowers water temperature to between 40° and 45°F before the water is pumped to the location to be cooled.

We provide the following type of panel fabrication services :-

Control Panels

PLC/DCS Systems

Custom Control Panels

Engineering and design

CAD Drawings.

Water Chiller

It is a mechanical device used to facilitate heat exchange from water to a refrigerant in a closed loop system. The refrigerant is then pumped to a location where the waste heat is transferred to the atmosphere.

In hydroponics, pumps, lights and ambient heat can warm the reservoir water temperatures, leading to plant root and health problems. For ideal plant health, a chiller can be used to lower the water temperature below ambient level; 68°F (20°C) is a good temperature for most plants. This results in healthy root production and efficient absorption of nutrients.

In air conditioning, chilled water is often used to cool a building’s air and equipment, especially in situations where many individual rooms must be controlled separately, such as a hotel. A chiller lowers water temperature to between 40° and 45°F before the water is pumped to the location to be cooled.

Profile Tube Bending Machinery

Sandeep Engineers, a manufacturer in tube bending machinery, supplies the most innovative CNC bending machines in the globe. The capacity is ranging from OD 6 mm to max 254 mm. Our machines are implemented in diverse industries including aviation industries, automotive industries, ship building, furniture making, HVAC, architecture, petrochemical pipelines … etc.

Attributed to our exclusive designs, CSM machines are significantly more compact and consolidated than other manufacturers. In addition to optimum performance, we assure you power efficient, energy economic and environment friendly.

We are offering high performance Pipe Bending Machine that are known for quality, efficiency and durability. This machinery is designed by our team of engineers and technicians taking immense care and using latest technology. These products are highly effective and have the ability to work in any conditions.

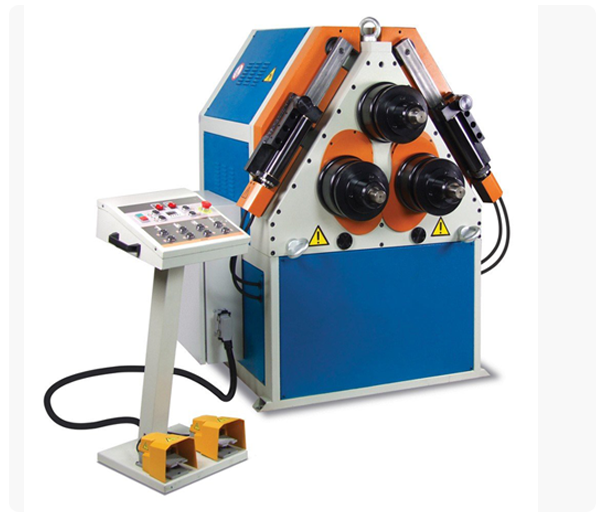

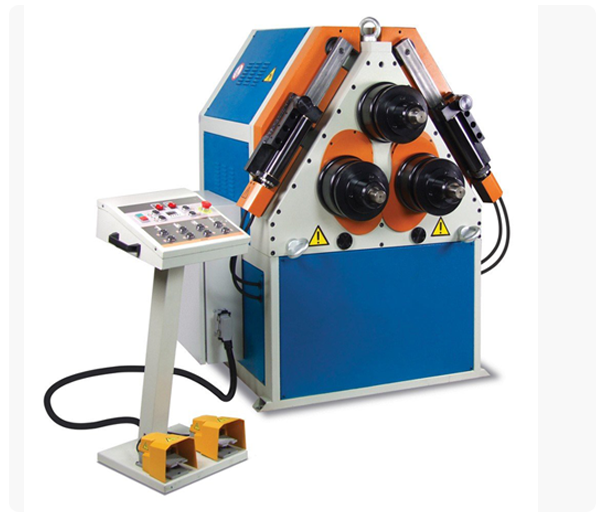

Profile Bending Machinery

Sandeep Engineers are the manufacturer of Bending Machines consists of a basic machine that can be adjusted with little effort and used for a variety of bends. A simple plug-in system supports quick and easy exchange of tools.

The basic machine consists of a CNC operated side stop, a work bench, and Windows Software for programming and operating. Its modular construction offers an affordable entry into the bending technology, because after an initial investion the machine can be customized and extended later on without any conversion. That mean the basic machine delivers a bending stroke, the tool determines the kind of bending.

All bends without an extraordinary geometry belong to standard bends. The distance between a bend and the material end is quite high providing an adequate bearing area. The same with one bend to the next. Typical tools are a so-called bending former combined with a prisms with electronic angular measurement or an ordinary prism.

Food Industry Mixer

Horizontal mixers consists of ribbon, plough and paddle mixers, which are designed for consistent batch and continuous blending of powder and granules with capacities ranging from 35 – 60,000 litres.

Models can be custom built to suit specific customer requirements, including alternative trough shapes , cantilever shaft design for easy access and the addition of side cutters or intensifiers for extra shear.

The table below shows our range of mixers including Ribbon, Plough and Paddle agitators and the various options available including low shear and high shear mixers.

TYPICAL APPLICATIONS

Dry powder mixing

Liquid addition into powders

Live storage of sticky powders

Cutting fat into flour

Addition of oils or other liquids into powders

Food Industry Mixer

Breaking down agglomerates

Sheet Bending Machinery

Sandeep Engineers is the provider of hand operated metal sheet bending machine which is designed for accurate and economical bending of standard and special design forms. Sheet folding machine is used for punching, cutting, bending and shearing sheet metal. Staying on top of the competition is key to your company’s success and so we pride ourselves on offering you an unbeatable quality of hand operated metal sheet bending machines.

We can offer hand operated metal plate bending machine in customized dimensions.

Hot Generators

Sandeep Engineers manufactures hot water boilers in the range of 50,000 to 90,00,000 kcal per hour. The hot water boilers are designed to operate on various types of fuels such as heavy oil, light oil, gas.

The standard Hot Generators is a unique 3-pass wet-back horizontal design, coil type water tube, packaged, Monobloc oil/gas fired, forced circulation hot water generator for high efficiency and easy maintenance. The Ecomatic is an extremely user friendly hot water generator, with a low electrical load giving more than 50% savings over electrical geysers. The Ecomatic is available in capacities from 50,000 kcal per hour to 10,00,000 kcal per hour maximum continuous rating.

Temperature upto 90 ºC firing fuels HSD, LDO, FO, NG & LPG and efficiency of 93 +/- 2% on NCV.

Several applications of indirect heating as well as hot water direct consumption can be achieved with hot water generators. Hotels, Hospitals, Dairies, Laundries etc are Industries where hot water boilers offers advantages over conventional steam or electrical heating systems.

Heating Mixer

It is a mechanical device used to facilitate heat exchange from water to a refrigerant in a closed loop system. The refrigerant is then pumped to a location where the waste heat is transferred to the atmosphere.

In hydroponics, pumps, lights and ambient heat can warm the reservoir water temperatures, leading to plant root and health problems. For ideal plant health, a chiller can be used to lower the water temperature below ambient level; 68°F (20°C) is a good temperature for most plants. This results in healthy root production and efficient absorption of nutrients.

In air conditioning, chilled water is often used to cool a building’s air and equipment, especially in situations where many individual rooms must be controlled separately, such as a hotel. A chiller lowers water temperature to between 40° and 45°F before the water is pumped to the location to be cooled.

Blore Fire System

Incorporated with a wide variety of features & specifications, we are offering our clients a quality assured range of Single Stage Oil Burners In Order to ensure is high performance , the machine has been made from only high grade quality raw material. Used in the processing of various metalluragic burning the offered range has been avalied to the customers in various specifications. We have offered this range to the patrons at the market leading price.

KEY FEATURES OF SINGLE STAGE OIL BURNERS.

Reliable Products-Supreme quality outstanding price/performance ratio.

Combustion Head is designed for High Performance & Low emission.

Customer Friendly Controlling System.

Fully Automatic Operation-available in single stage/two stage/modulating version.

Suitable for HSD , LDO , & SKO Oils.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.