SAHAJANAND LASER TECHNOLOGY LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SAHAJANAND LASER TECHNOLOGY LTD

Laser Cutting System

Laser Cutting System

BALL RAIL SYSTEM

Smooth & friction guided motion, high precision & high speed ball, long life & better load carrying capacity.

BALL SCREW MECHANISM

Precision movement imparted through ball screw mechanism. Supreme quality of ball screw to provide high accuracy and repeatability at high speed with low noise runner block.

USER FRIENDLY SOFTWARE

User-friendly software for laser power and pulse frequency, pulse duration along with position control.

NESTING

Nesting software to nest different types of jobs in single sheet and optimal use of raw material. Accommodation of different types of jobs from scrap material & common edge cutting. Complete material management through user-friendly software.

HEIGHT SENSING UNIT

Adjusting preset height automatically. It helps to cut little sloppy (non-flat or non-linear) surface of sheet. Non-contact & contact types of versions are available.

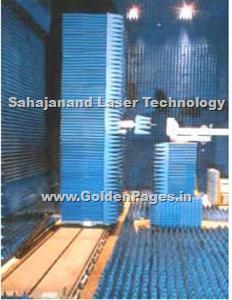

STRUCTURAL DESIGN

Structural design is such that it can withstand heavy loads. Vibration pads are used for sustaining the structural damping.

Laser Marking System

PERMANENT

Laser marking is permanent and indelible marking process, which stands against wiping, scuffing, impacts, wear and tear, can only be removed by grinding or surface removal. Thus laser - marking sustains authenticity of your brand against sort of tempering

NON-CONTACT TYPE

Laser marking is non-contact type process. It does not produce any deformation in product unlike in punching, stamping, pneumatic pin, vibratory pencil etc. This gives accurate and aesthetic marking independent of hardness of material.

FLEXIBILITY

Laser marking is highly flexible process compared to any other marking process. It can mark any images and fonts without changing any punch, die, stencil etc. unlike other conventional process.

AESTHETIC/ACCURACY

Since laser can produce very fine beam with accuracy in micron, many accurate and micro details with precision can be marked with laser marking. Laser can produce aesthetic images which otherwise difficult to create with other marking process.

Laser Welding System

Laser Welding System

f

COMPREHENSIVE.....

From SLT Ltd., you get state of art technological laser systems designed by our own engineers and CAD draughtsman and specially tailored to your needs. This is why from SLT Ltd. you get comprehensive laser competency from A to Z.

USER FRIENDLY.....

The SLT Ltd. LWI Chambertype unifies intuitive operation, excellent design and ergonomics in fascinating way. Convince yourself.

CUSTOM MADE.....

The innovative SLT Ltd. LWI Chambertype offers flexible solutions in individual applications. Customer specific modifications are made easily, at any time, from spot diameter and focus length to pulse modulation and handling systems.

ECONOMICAL.....

The SLT Ltd. Chambertype stands for the highest performance and functionality at an unbeatable and really exceptional cost-performance ratio. Because quality must be affordable.

Solar Cell Scribing System Sly

WHAT IS SOLAR CELL?

A photovoltaic cell (commonly called a solar cell) is a nonmechanical device usually made from silicon alloys. It converts sunlight into electricity. The PV cell was discovered in 1954 by Bell Telephone researchers. Late 1950s, PV cells were used to power U.S. space satellites.

Individual cells can vary in size from about 1 cm (1/2 inch) to about 10 cm (4 inches). Most photovoltaic cells are about ten percent efficient in covering sunlight to electricity with further research being conducted to raise this efficiency to fifteen-twenty percent.

Photovoltaic conversion is useful for several reasons. Conversion from sunlight to electricity is direct, so that bulky mechanical generator systems are unnecessary. The modular characteristic of photovoltaic energy allows arrays to be installed quickly and in any size required or allowed.

Presently BCSC (Buried Contact Solar Cells) and Polycrystalline CdTe-baser Photovoltaic are the latest technology in the solar cells and having efficiency is around 15-20 % approx. and we can get stable power output and long life.

Cnc Solution

Gantry or cantilever design.

Ball rail systems for higher speed operations.

Arc voltage sensor for optimal cut quality.

The nozzle/ torch does not get damaged by touched directly to the plate.

0.5 mm to 150 mm in stainless steel and most other metals.

Negligible distortion/warpage due to low heat effected zone.

Flexible controller with in-built macros and nesting.

Vibration Pads are used for sustaining the structure damping.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.