ROOP TELSONIC ULTRASONIX LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ROOP TELSONIC ULTRASONIX LTD.

Ultrasonic Bath

Ultrasonic bath works on the principle of Ultrasonic cavitation i.e. high frequency vibrations, generate agitation in liquid resulting into rapid formation and collapse of minute bubbles in liquid. Implosion of bubbles with high pressure on exposed surface of component dislodges and removes contamination like dirt, dust, oil, grease, chips, wax, lapping paste, carbon etc.

Features

- Latest technology.

- Very simple operation.

- Generously dimensioned heating system for rapid heating of the liquid, thermostatically continuously variable between 20 and 80°C.

- Complete unit made of stainless steel, easy maintenance and drip-proof.

- Timer operation 1-99 min and continuous operation.

- Remaining cleaning time is optically displayed.

- Ultrasonic frequency 30 kHz.

- Tank contents 1.5 - 28 ltr.

- Digital Control of time and temperature.

- Longer tank life.

- Low noise level.

- Suitable for continuous operation.

- Rugged and easy to clean stainless steel housing.

- Fully transistorized generator.

- Automatic frequency tuning for maximum output.

- Maintenance-free.

Ultrasonic Cleaning Systems

High Precision Industrial Ultrasonic Cleaning Systems

Highest Cleaning Quality Through Advanced Industrial Cleaning Techniques

Till today, many industries use chlorinated solvents for cleaning various components. Although solvent based cleaning system like ultrasonic vapor degreasing systems does give good cleaning results but adopting new technology has become imperative to avoid use of highly chlorinated solvents due to strict environmental regulations worldwide.

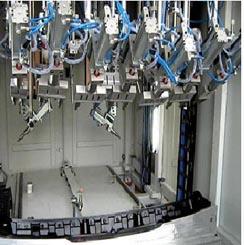

A highly advanced semi-automated / automated high efficiencyultrasonic cleaning systems are built depending on the job specifications. High quality aqueous solutions not only offer efficient alternative cleaning but also allow maximum environment & labor protection, highest cleaning quality with better output, low solution & energy consumption, easier waste disposal etc.

We at ROOP TELSONIC offer you highly sophisticated & modern AQUEOUS BASED ultrasonic cleaning systems consisting of various cleaning, rinsing & drying stages. Depending on the cleaning tasks, complete systems are provided with filtration & recovery units, oil separators. The desired cleaning result is achieved by rotation, lifting/lowering movements of the baskets.

Ultrasonic Cleaning Components

The success of a large cleaning system depends mainly on Ultrasonic Generators and Transducers. We offer efficient ECO-Generators. Due to their compact design they require less space and are usable in a raw environment. This is allowed by an indirect cooling which ensures that the cooling air does not get in contact with the electronic components.

The generators all-purpose housing allows the application as a table top version in 19'' switch boards or DIN-rails. The ECO's power spectrum includes 750 W to 1500 W for tube resonators and immersing transducers.

Eco generator

Advantages

- Table top version, 19“-Rack mounted version, DIN-rail-mounting or wall fastening.

- Three free programmable relay outputs.

- Five DC-isolated 24 V inputs, for external power setting.

- Fully automatic control and monitoring.

- Overtemperature and overcurrent turn off.

- Protected spelling short-circuit and no-load operation.

- Coefficient of efficiency >90 %.

- Optional communication via RS-232 interface.

- Designed for tube resonators, immersing transducers and transducer plate fitted to tanks.

Industrial Tanks

The demand for industrial cleaning has been ever increasing as highly cleaned components are in-dispensable for various production units. This is not only to create conditions for trouble free manufacturing but also decides the quality and service life of the product. Which cleaning should be applied for demand will depend on various aspects: type of component, material, surface quality, type of contamination and required cleanliness.

Ultrasonics can remove all kinds of dirt and other particles such as grinding and polishing residue, as well as oil, grease. Its scope of application ranges from cleaning the movement of a watch to overhauling the engines of a Jumbo jet.

Features of RTUL Industrial Cleaners

- Ultrasonic and heat insulation.

- Sloped floor for complete emptying.

- Edged work area prevents liquid from dropping down.

- Beveled cover guides water condensation back to the tank.

- Protection against dry running for ultrasound and heating.

- Ultrasonic generator is integrated.

- Temperature regulation.

- Timer for ultrasonic activity.

- Contents of 50, 70, 110, 170, 250 liters.

- Working frequencies 25, 40 kHz.

- Tank, cover, sheathing and drainage tap made of stainless steel.

- Overflow edge with connection (set watertight).

- We also manufacture Industrial ultrasonic cleaners with filtration capability.

Method Of Cleaning

Method Of Ultrasonic Cleaning

Ultrasonic cleaning is used in different industry branches. Ultrasound travels in liquids in form of a longitudinal wave. These longitudinal waves produce areas with overpressure and vacuum which have influence on the evaporation of the liquid.

A liquid is conjoined through cohesions. If the intensity of ultrasonic intensity is increased in the liquid continuously, the liquid will partially evaporate in the vacuum phase and microscopic tiny steam bubbles emerge.

In the following overpressure phase, the steam bubbles implode (cavitation). In this procedure, extreme high forces arise leading to micro blast waves and micro streaming.

The cavitation is influenced by a lot of parameters. It is depending on the external pressure, the temperature, the sonic frequency and intensity, the type of liquid and other sonic values.

Finally, the cavitation causes an excellent cleaning effect comparable to the attack of countless micro brushes.

Advantages of Ultrasonic Cleaning

- Easy handling.

- Shorter cleaning time.

- Less chemistry.

- Low cleaning temperatures.

- Reproducible result .

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.