RIECO INDUSTRIES LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to RIECO INDUSTRIES LTD.

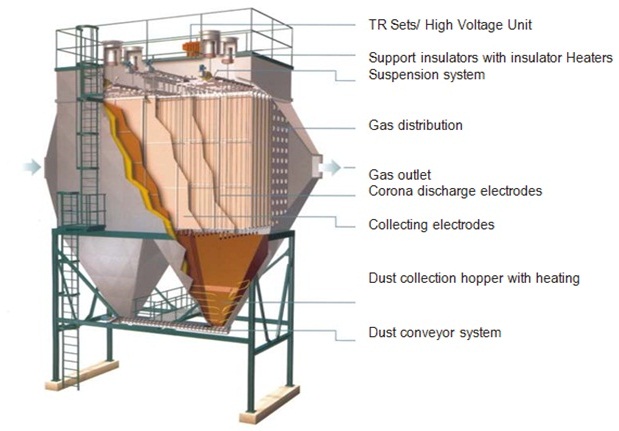

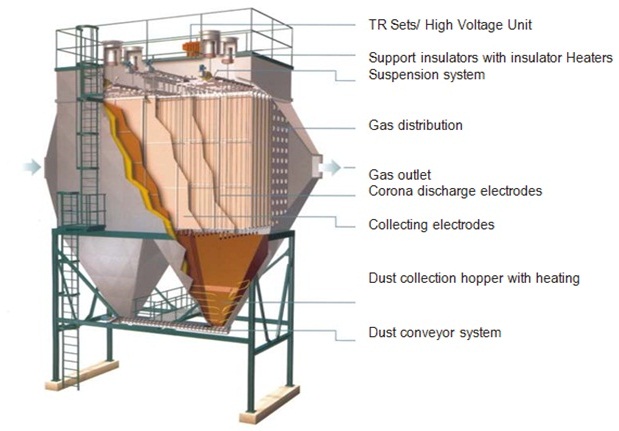

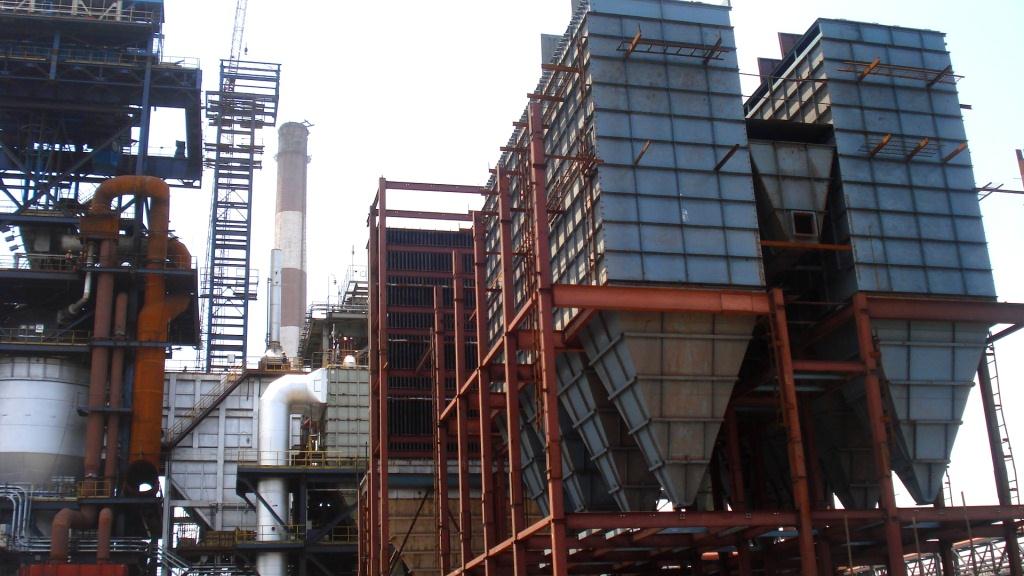

Dry Esps

The RIECO dry Electrostatic Precipitator (ESP) can be used to extract fine dust particles from process gases up to a temperature of 400 Celsius by means of an artificial electrostatic charge. The dust-laden process gas enters the ESP horizontally, and is spread to a uniform flow profile across the entire filter cross-section by means of a gas distribution system. By means of the high voltage applied between the corona discharge electrodes and the collecting electrodes, the process gas and the dust particles are electrically charged.

On the route through the electric field, the charged particles are transported to the collecting electrode plates by the electric field strength, where they agglomerate with the existing dust particles which are then knocked off by a motorized tumbling type Rapping Hammer System. The rapped off dust particles drop into the ESP hopper and are removed through the dust discharge system. The clean gas leaves the ESP through the gas outlet cone.

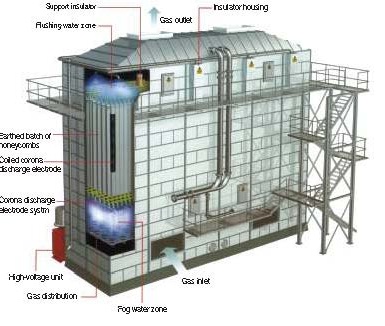

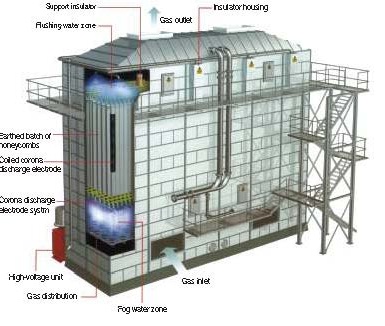

Wet Esps

The process gas enters the wet ESP horizontally, and is spread to a uniform flow profile across the entire filter cross-section by means of a gas distribution system. By means of the high voltage (78 to 135 KV) applied between the corona discharge electrodes and the specially designed honeycomb-type collecting electrodes, the process gas and the dust particles are electrically charged. On the route through the electric field, the charged particles are transported to the honeycomb type collecting electrodes by the electric field strength where they agglomerate with the existing dust particles and are flushed off by a periodically working washing system. The drain water flows from the honey comb through the gas distribution system to the filter bottom. The purified gas leaves the filter through the gas outlet hood

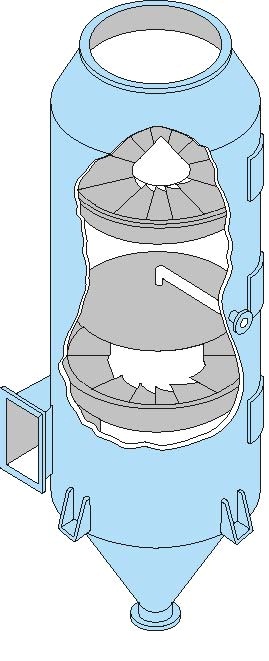

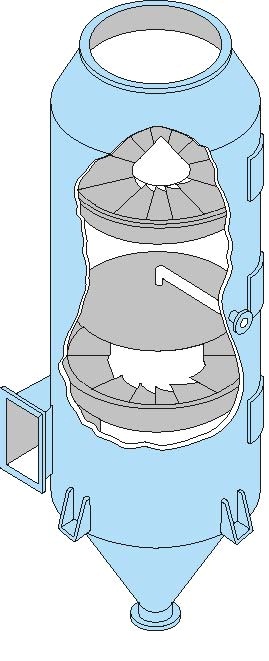

Scrubbers

Description / Specification of Scrubbers

We are involved in offering a wide range of Scrubbers to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Scrubbers. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

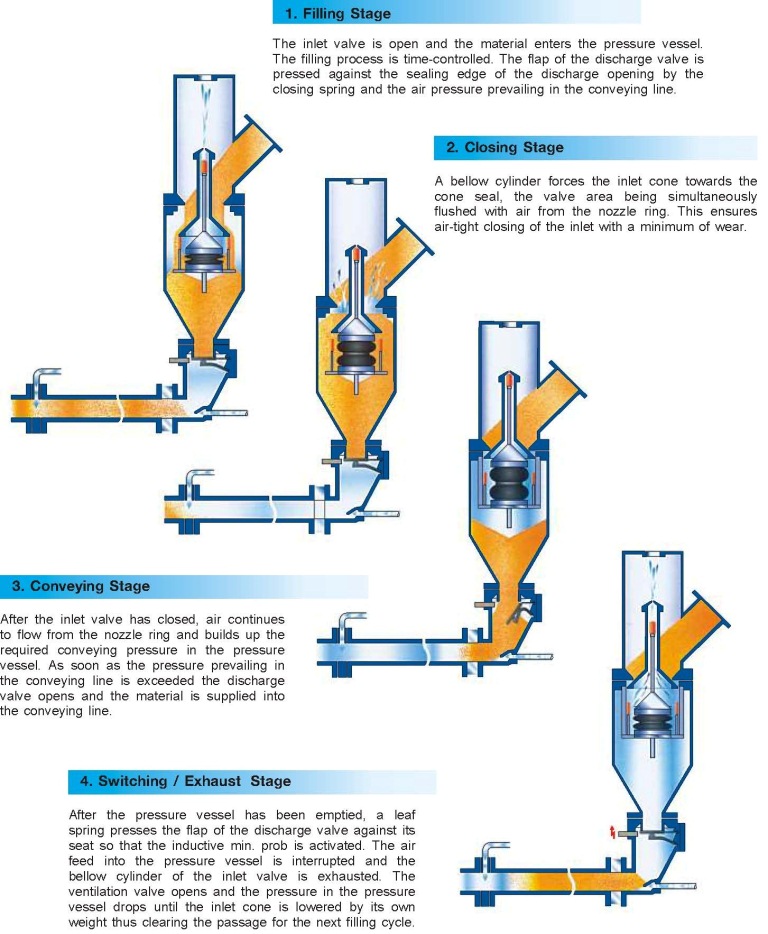

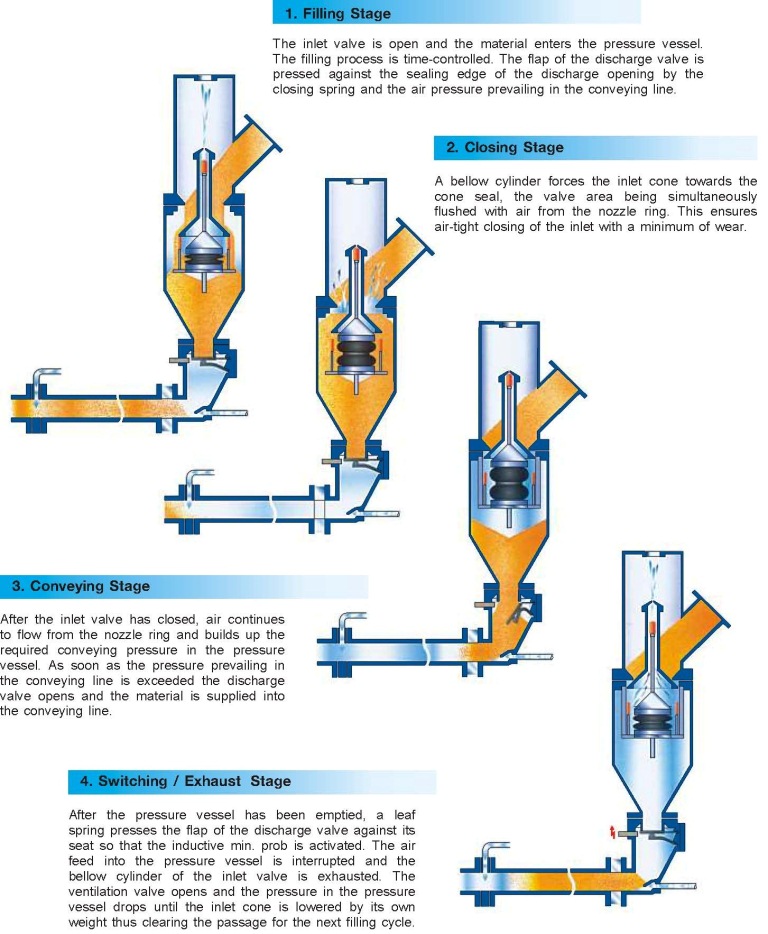

Pneumatic Handling Systems

There are distinct advantages of our system in contrast to conventional conveyors, in which the conveying process is interrupted in order to decrease the conveying pressure and refill the pressure vessel.

Besides having a very compact design and higher conveying capacities, there is considerable lower extent of wearing of the conveying pipes and conveying material.

There is relatively less wastage of air and subsequent reduced strain on the filters. The cone is air flushed and the integrated electro-pneumatic timing control is clocked by one inductive switch. All this results in considerable savings during operations, reduced preventive inspections and a system that displays stability and performs flawlessly.

Engineering Services

In projects that have space constraints to accommodate the required equipment or in cased where the layout requirements are crucial, our squad of experienced and energetic engineers is always willing to extend all the required support.

First they will interact closely with your Engineering team in office and your Consultants, to understand your requirement with the available data of Plan and Elevation drawings. Then they will offer to make a site visit to take actual measurements if required, and inspect the location where the proposed equipment is planned to be installed.

With the rich experience and understanding accumulated over the years, our engineering team will also share the same freely with your team in order to mutually freeze the most convenient, favorable and technically ideal layout for your plant.

Site Services

Nobody knows our equipment as well as we do. Hence it is prudent to avail our expert services when it comes to erecting, installing, commissioning or operating a system, or equipment supplied by RIECO. This is a sure shot formula to ensure your equipment is always working at peak efficiency. Technical services include Energency Site services, Supervisory services and Erection services.

Also in unforeseen circumstances, should you unfortunately require any emergency service and repair, our alert team of Technical Services are always prepared to respond promptly, in order to get your equipment back on track and working normally.

Equipment Inspections

Following prior intimation of scheduled shutdowns inspection of your APC, SRE or PHS equipment can be carried out by our specific experts. They will not only examine the actual installation or machine but also require data from your records pertaining to previous operation logs, maintenance records, production output, power consumption, outlet emission records etc.

Our experts will not only point out deficiencies in the operation systems if any, they will also advice on ways to improve the performance of the equipment and maximizing your output out of the equipment.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.