PRASHANT GALVANIZERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PRASHANT GALVANIZERS

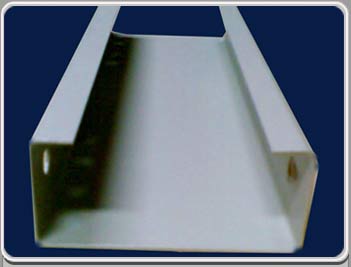

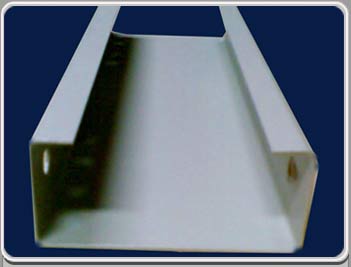

Cable Trays

Cable Trays are especially suited for laying out of the electrical as well as instrumentation power cable for the power connection on various stage in the plant.

Advantage of Cable Trays :

Savings in supporting steel work.

Savings in Labour Cost.

Easier to assemble.

Cable fault can be easily traceable.

No Cropping.

No Re-drilling.

Greater strength.

Extra cable carrier can be fitted.

Ventilated designed for air vant.

Other Details :

Generally we supply the cable trays in 2500mm standard length. However we consantrate to the client’s specification/drawing.

Product Range

Perforated Type CableTrays: 50mm (Width) To 600mm(Width)

Ladder Type Cable Trays: 150mm (Width) To 1200mm(Width)

Sheet Thickness: 1.6mm To 3.15mm

Construction: Construction of CableTrays will be as per the client’s specification/approved drawing.

Raw-materials of our products :

Generally we use M.S./Alluminium Sheets, Structural Forms viz. Angles, Channels, Beam, Plates, Flats, Rounds…etc. Zinc, Primers & Paints. All these we purchases from the reputed manufacturers/traders with required Test Certificates.

Finish:

Generally we supply our products with the finish of Hot Dip Galvanized, Primer coated, Enameled paint coated OR Epoxy paint coated.

Inspection:

A simple physical and laboratory tests to be conducted on the random selected samples with the following steps as per the requirements.

Visual Check Test.

Thickness of zinc coating Test as per IS-6745/IS-4759/IS-3203.

Adhesion Test as per IS-2629.

Uniformity of Zinc coatings Test as per IS-2633.

Utility:

Our products being used by Power Plants, Cooling Towers Manufacturers, Railways, Refinery Projects, Fertilizer Industries, Cement Factories, Petrochemical Projects and Large Scale of Industrial Units.

Crash Barrier

Crash Barriers also widely known as Armco barriers or traffic barriers are designed to safeguard the vehicles from colliding with hazardous barriers like buildings, boulders, large storm drains or walls. Additionally, these crash barriers can even be placed at the road side in order to avoid errant vehicles from entering deep waters or going through steep slopes. The reason behind the existence of these barriers is basically to reduce the collisions. Hence, they are installed within medians of divided highways so that they are able to prevent such unorganized and wayward vehicles from entering the opposing carriageway of traffic. It is always advisable to use these crash barriers to shield vulnerable areas like pedestrian zones, school yards or fuel tanks.

Roadside accidents that are met due to ignorance or casual approach towards driving can lead to many life threatening events. Similarly, one should even be careful about the factors that can pose a danger to traveling motorists and should come out with preventive measures like small roadside signs. With a crash barrier need, another need that comes along is proper calculations determining length of the need, speed and traffic volume. Crash barriers can be placed at bridge ends, drainage crossings, near steep slopes, near large signs or illumination poles that may pose danger.

Different types of crash barriers that can be used as per the requirement are:

- Roadside barriers

- Median barriers

- Bridge barriers

- Work zone barriers

These barriers can either be flexible, semi-rigid or rigid. Hence, depending on the requirement and where it needs to be installed, one should decide the type of crash barrier to be used so that it works as the best safeguarding factor for the travelling motorists.

Race Ways

A Raceways is an enclosed conduit that forms a physical pathways for electrical wiring. Raceways protect wires and cables from heat, humidity, corrosion, water intrusion and general physical threats. It is ideal for wire management in computer and communication system. A well grounded metallic conduits provides radio frequency shield that minimize the risk of trouble with electro magnetic interference. In some system plastic conduit is used mainly to contain coaxial cables OR other forms of cables that have their own Raceways are an important component in the design of complex data centre and blade server.

Raw-materials of our products :

Generally we use M.S./Alluminium Sheets, Structural Forms viz. Angles, Channels, Beam, Plates, Flats, Rounds…etc. Zinc, Primers & Paints. All these we purchases from the reputed manufacturers/traders with required Test Certificates.

Finish:

Generally we supply our products with the finish of Hot Dip Galvanized, Primer coated, Enameled paint coated OR Epoxy paint coated.

Inspection:

A simple physical and laboratory tests to be conducted on the random selected samples with the following steps as per the requirements.

- Visual Check Test.

- Thickness of zinc coating Test as per IS-6745/IS-4759/IS-3203.

- Adhesion Test as per IS-2629.

- Uniformity of Zinc coatings Test as per IS-2633.

Utility:

Our products being used by Power Plants, Cooling Towers Manufacturers, Railways, Refinery Projects, Fertilizer Industries, Cement Factories, Petrochemical Projects and Large Scale of Industrial Units.

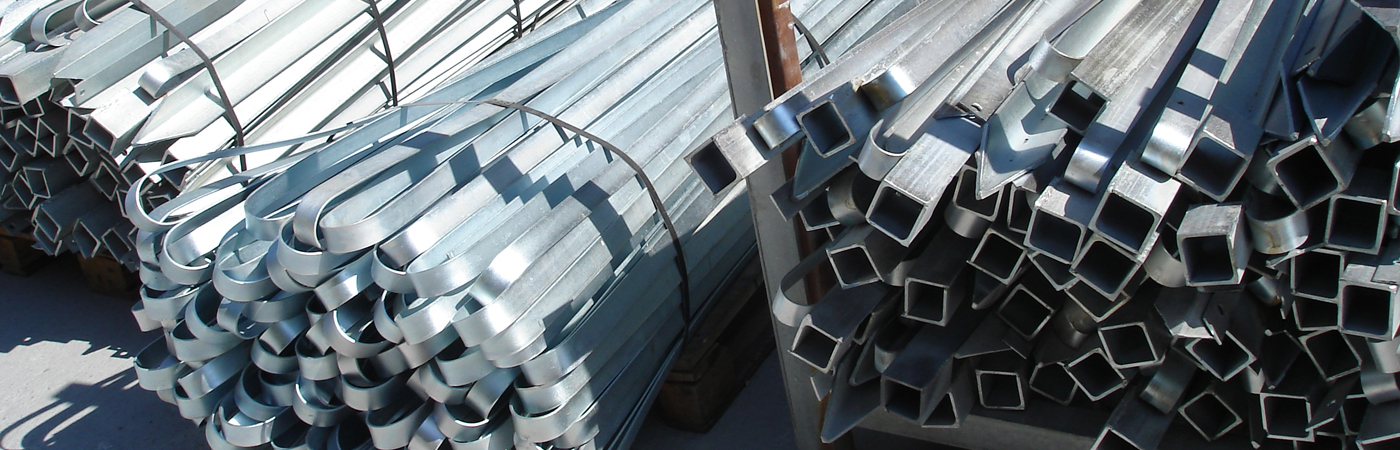

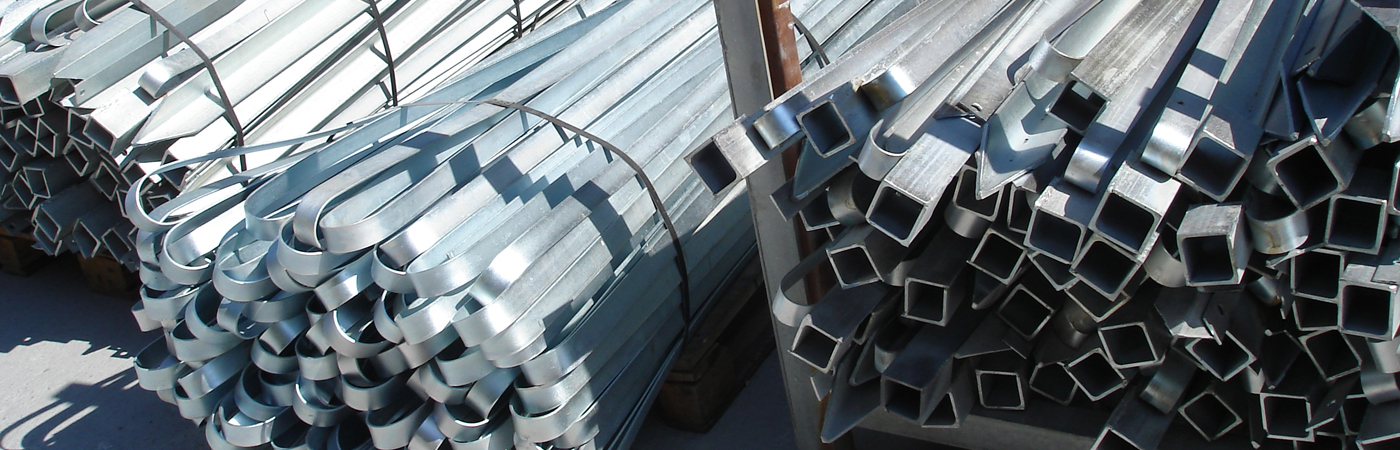

Earthing Strips

Description / Specification of Earthing Strips

We are involved in offering a wide range of Earthing Strips to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Earthing Strips. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Earthing Materials

A List of Earthing Products :

- Galvanized/Copper and Alluminium Earth Strips/Bars.

- Galvanized/Copper and Alluminium Solid Earth Plate.

- Solid Copper Lattice Mat.

- Earth Electrodes.

- Light Duty/Heavy Duty Cast Iron Inspection Housing.

- Galvanized/Copper/Alluminium Earth Bus Bars.

- Flexible Copper Braid Bonds.

Earthing Materials are to be used for earthing and lightening protection. A well designed earthing system is essential to ensure protection of personnel and equipment from danger associated with fault current. To achieve an efficient earthing system, it is essential that a low electrical resistance to earth is achieved using good quality conductor with sufficient cross sectional areas to carry the expected current flow. The conductors must also have a high corrosion resistance. Earth resistance should be regularly checked. Corrosion and fault current can cause high resistance joints leading to overheating. However if an earth system Is correctly installed and maintained well, it should last for many years.

EARTHING STRIP

We have an expert facility for manufacturing a highly functional range of earthing strip. Latest procedures for galvanizing are used for these earthing strips. They are used in various applications in automobile, engineering, electrical and other industries. Owing to dimensional accuracy, these strips possess outstanding electrical and thermal conductivity and are thus widely demanded in the global market.

Raw-materials of our products :

Generally we use M.S./Alluminium Sheets, Structural Forms viz. Angles, Channels, Beam, Plates, Flats, Rounds…etc. Zinc, Primers & Paints. All these we purchases from the reputed manufacturers/traders with required Test Certificates.

Finish:

Generally we supply our products with the finish of Hot Dip Galvanized, Primer coated, Enameled paint coated OR Epoxy paint coated.

Inspection:

A simple physical and laboratory tests to be conducted on the random selected samples with the following steps as per the requirements.

- Visual Check Test.

- Thickness of zinc coating Test as per IS-6745/IS-4759/IS-3203.

- Adhesion Test as per IS-2629.

- Uniformity of Zinc coatings Test as per IS-2633.

Utility:

Our products being used by Power Plants, Cooling Towers Manufacturers, Railways, Refinery Projects, Fertilizer Industries, Cement Factories, Petrochemical Projects and Large Scale of Industrial Units.

Sub Station Structures

A List of the types of the supporting structures :

- Lightening Arrestor.

- Post Insulator.

- Beam.

- Current Transformers.

- Power Transformers.

Sub-Station Structures are used to support power grid components and electrical equipments. Sub-Station Structures shall be fabricated from latticed angles, Pipes, Plates … etc. A common definition for sub-station structure is an assembly of equipments.

Switchyard Structure is generally applied for the assembly of switches, power circuit breakers, buses and auxiliary equipment, which are used to collect power from the generators of power plant and distribute to the transmission line at a load point. As far as structures are concerned the terms, Sub-Station and Switchyard structures will be used interchangeably

Transmission lines are power lines typically with voltage at 66KV and above. Voltage than 66KV are usually referred to as distribution lines. Transmission Line Sub-Station Structures are to be used for protection of Sub-Station equipments. Shield wires may also used for communications.

Electrical clearances provides physical separation needed for phase to phase, Phase to Structure and phase to grounds air gap to provide safe working areas and to prevent flashover.

RAW-MATERIALS OF OUR PRODUCTS :

Generally we use M.S./Alluminium Sheets, Structural Forms viz. Angles, Channels, Beam, Plates, Flats, Rounds…etc. Zinc, Primers & Paints. All these we purchases from the reputed manufacturers/traders with required Test Certificates.

Finish:

Generally we supply our products with the finish of Hot Dip Galvanized, Primer coated, Enameled paint coated OR Epoxy paint coated.

Inspection:

A simple physical and laboratory tests to be conducted on the random selected samples with the following steps as per the requirements.

- Visual Check Test.

- Thickness of zinc coating Test as per IS-6745/IS-4759/IS-3203.

- Adhesion Test as per IS-2629.

- Uniformity of Zinc coatings Test as per IS-2633.

Utility:

Our products being used by Power Plants, Cooling Towers Manufacturers, Railways, Refinery Projects, Fertilizer Industries, Cement Factories, Petrochemical Projects and Large Scale of Industrial Units.

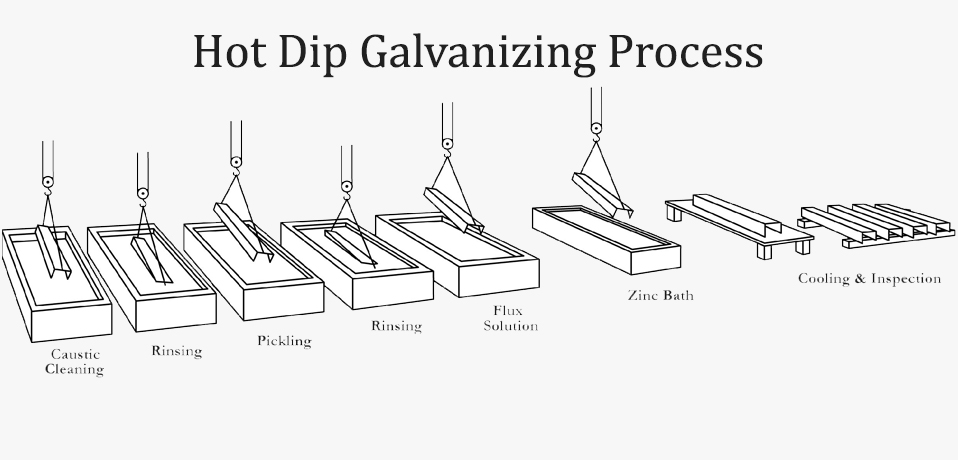

Hot Dip Galvanization

Hot Dip Galvanizing Process is a technical process for applying zinc coating on iron and steel surface to protect against corrosion. The zinc coating firstly protect the base metal by acting as an impervious shield between the metal and the atmosphere and secondly afford sacrificial protection even when moderately sized area of the base metal surface are exposed.

Hot-Dip-Galvanization

UNIQUE SELLING POINT (USP) :

Surface preparation is the most important factor in the application of the zinc coating on the iron component surface area. Due to incorrect OR in adequate surface preparation, zinc coating could not be processed properly.

Finish:

Generally we supply our products with the finish of Hot Dip Galvanized, Primer coated, Enameled paint coated OR Epoxy paint coated.

Inspection:

A simple physical and laboratory tests to be conducted on the random selected samples with the following steps as per the requirements.

Visual Check Test.

Thickness of zinc coating Test as per IS-6745/IS-4759/IS-3203.

Adhesion Test as per IS-2629.

Uniformity of Zinc coatings Test as per IS-2633.

Utility:

Our products being used by Power Plants, Cooling Towers Manufacturers, Railways, Refinery Projects, Fertilizer Industries, Cement Factories, Petrochemical Projects and Large Scale of Industrial Units.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.