PRAJ HI PURITY SYSTEMS LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PRAJ HI PURITY SYSTEMS LTD.

Core Processes

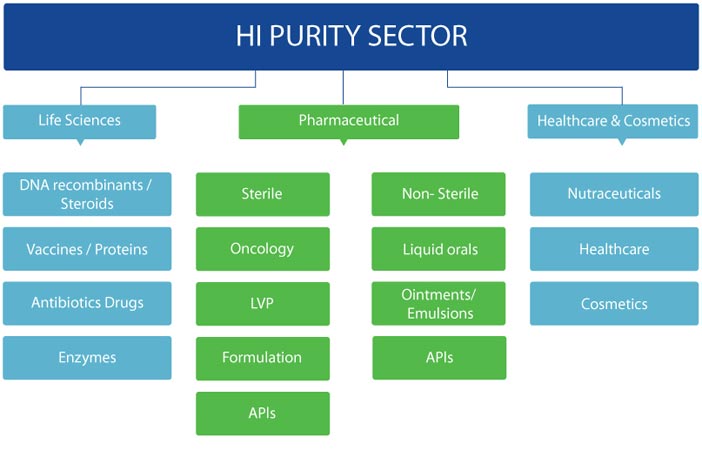

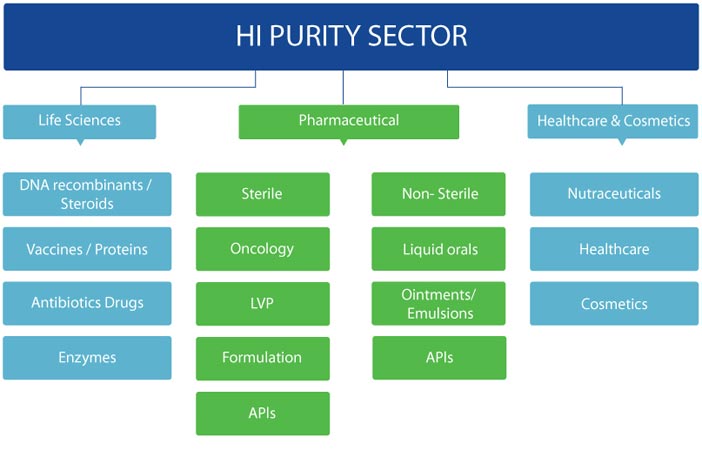

With the policy of providing end-to-end solutions to customers, Praj HiPurity Systems distinguishes itself as a Complete Solution Provider for Core Process Solutions to cater solely to the ever growing Pharma, Life Sciences, Healthcare & Cosmetics industries that have based their quality standards foundation set by regulatory bodies across the globe and manufacturing systems which are compliant to guidelines such as ASME-BPE, cGMP, GMP. We understand the process requirements and design our systems based on the criticality of the manufacturing processes and provide solutions with combination of technology and engineering with exceptional quality control for pharma industry producing parenteral drugs, syrups, suspensions, vaccines, enzymes, monoclonal antibodies etc. With vast experience, we deliver the best value for the money to our clients.

Hipurity Water Systems

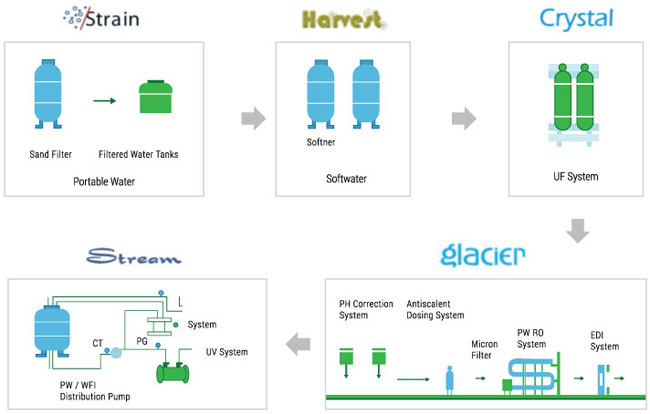

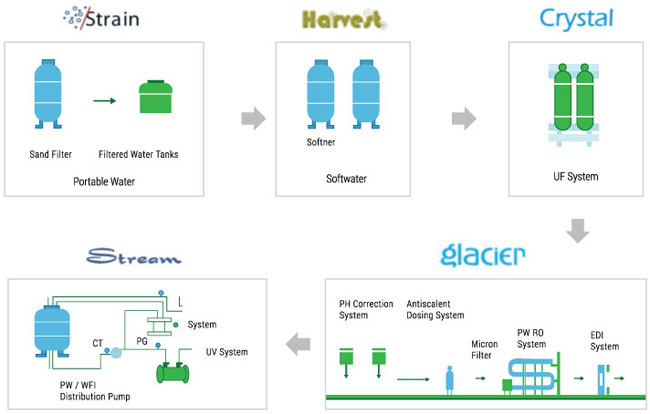

Praj HiPurity Systems with its vast experience stands out as turnkey solution provider for Purfied Water (PW), Highly Purified Water (HPW), Water for Injection (WFI) storage & distribution system, Clean utilities distribution systems to the Pharma, Lifesciences, Healthcare & Cosmetics industries that have based their quality standards foundation set by regulatory bodies across the globe such as USFDA, UKMCA, MHRA, WHO and manufacturing systems which are compliant to guidelines such as USP, ASME-BPE, cGMP, GMP. With vast experience of serving the industry for over 20 years, we have successfully installed & commissioned varied range of customized offerings in India as well as abroad.

Bioreactors And Fermenters

A bioreactor may refer to any manufactured or engineered device or system that supports a biologically active environment. A bioreactor/fermenter is equipment in which a controlled environment is provided for the fermentation processes. It is the system which helps to grow, maintain the micro organisms/ cells in controlled environment.

Generally the system used for Microbial fermentation process is called a Fermenter. AND the one which is used for cell culture (mammalian/insect cell) fermentation process is called Bioreactor.

Cip And Sip Systems

Benefits CIP/SIP System:

Based on Time Action Flow Chemical Temperature cleaning cycle principles

Defined module and automation

Compliance to ISPE, ASME-BPE, cGMP guidelines

Easy to integrate with existing process system with all the essential analytical instruments

Custom designed as per process requirements

Cost and reliability gains from reduced manual work and reduced risk of accidental recontamination

Consistent cleaning efficiency with minimum CIP fluid requirements

Ensures efficient, automatic cleaning of process lines and vessels

Wastewater Solutions

The latest waste water treatment & recycling technologies like biomethanation, water recycle & reuse and zero liquid discharge have been mastered at Praj HiPurity Systems. Being a knowledge based company with over 30 years of experience, we have the ability, technology & facility to design the most effective biomethanation, water recycle system, water reuse options and zero liquid discharge process as per the client’s unique requirements, no matter in which part of the world.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.