ORIENTAL RUBBER INDUSTRIES LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ORIENTAL RUBBER INDUSTRIES LTD.

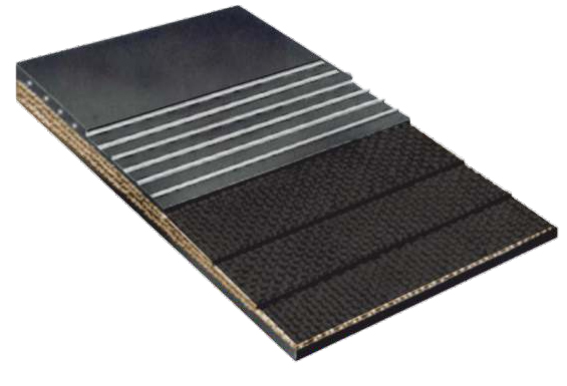

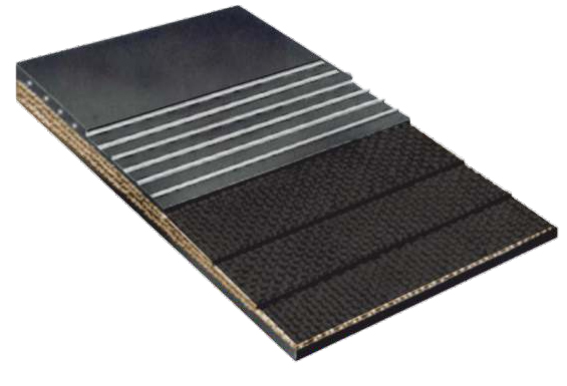

Steel Cord Belts

Conveyor belts having a steel carcass have multiple advantages over the regular fabric reinforced conveyor belts. They can run at higher speeds and longer length. They have inherently high strength and very low elongation which reduces the overall life-cycle cost of running a conveyor. The excellent joint strength and joint efficiency are the qualities which make our MAXX STEELFLEX range of steel reinforced conveyor belts stand out from the rest of the competition.

Cut Resistant Belts

The MAXX SHIELD belt is mainly designed to prevent belt failure due to entrapment of tramp material causing longitudinal cut or ripping of the entire belt. The loss due to such breakdowns is very high considering the entire length of belt which is lost and the ensuing production loss due to the unpredictable failure.

A specially designed steel breaker fabric is embedded in the top rubber cover. The steel cord running across the width of the belt arrests ripping, dislodges the tramp material out and thereby prevents longitudinal cut of the belt. If there is a history of belt ripping in any particular installation, we strongly recommend our MAXX SHIELD belt.

Fire Resistant Belts

One of the main hazards to which a conveyor system is prone to is Fire. Since general purpose conveyor belts are combustible, in certain areas which are exposed to fire risk, we recommend the use of fire resistant belts. The effect of a fire entails a safety hazard for the personnel as well as Potential financial loss caused due to damage to the Installation and of course substantial production loss Which follows any such breakdown.

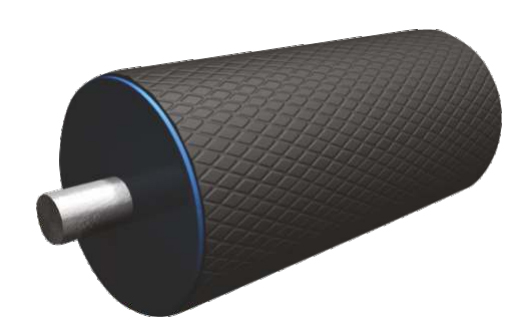

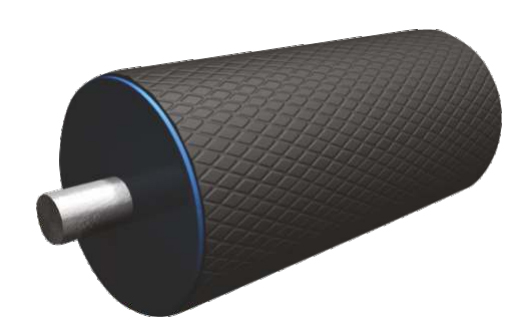

Ceramic Pulley Lagging

The MAXX TRAK Ceramic lagging system delivers an immediate, cost effective solution to conveyor belt drive problems and additional long term benefits to the total system! The uniquely designed lagging and high quality materials used in the manufacture of the product ensures continuous system operation under the most severe operating conditions where other systems fail!

Rubber Pulley Lagging

MAXX GRIP is designed to increase transmission power from the drive pulley to the belt. Slippage between a conveyor belt and a bare drive pulley causes low transmission of power due to following reasons:

- Low coefficient of friction

- Acute wrap angle

- Low pre-tension of the belt

MAXX GRIP offers the most cost efficient way to avoid these problems.

Chevron Belts

In conveyor systems having incline angles greater than 18 degrees, the material tends to roll back. To counter this the conventional approach is to increase the speed of the conveyors, thereby resulting in increased energy consumption.

With our experience in tackling problems related to high inclines, we have developed a diverse range of Chevron and other profile belts. Our range of MAXX ELEV conveyor belts are guaranteed to improve operational efficiency and throughput of material conveyed, be it crushed stone or wood chips.

Rubber Sheets

ORIENTAL’s wide range of DURO MAXX Sheets made out of Natural rubber and Synthetic rubber, are available in varying colours, thicknesses & widths. The DURO MAXX range can be supplied with our special bonding layer. When used in dynamic and impact applications, we recommend customers to use our products with the bonding layer since it provides a higher bond strength between the rubber and the steel surface due to its unique formulation.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.