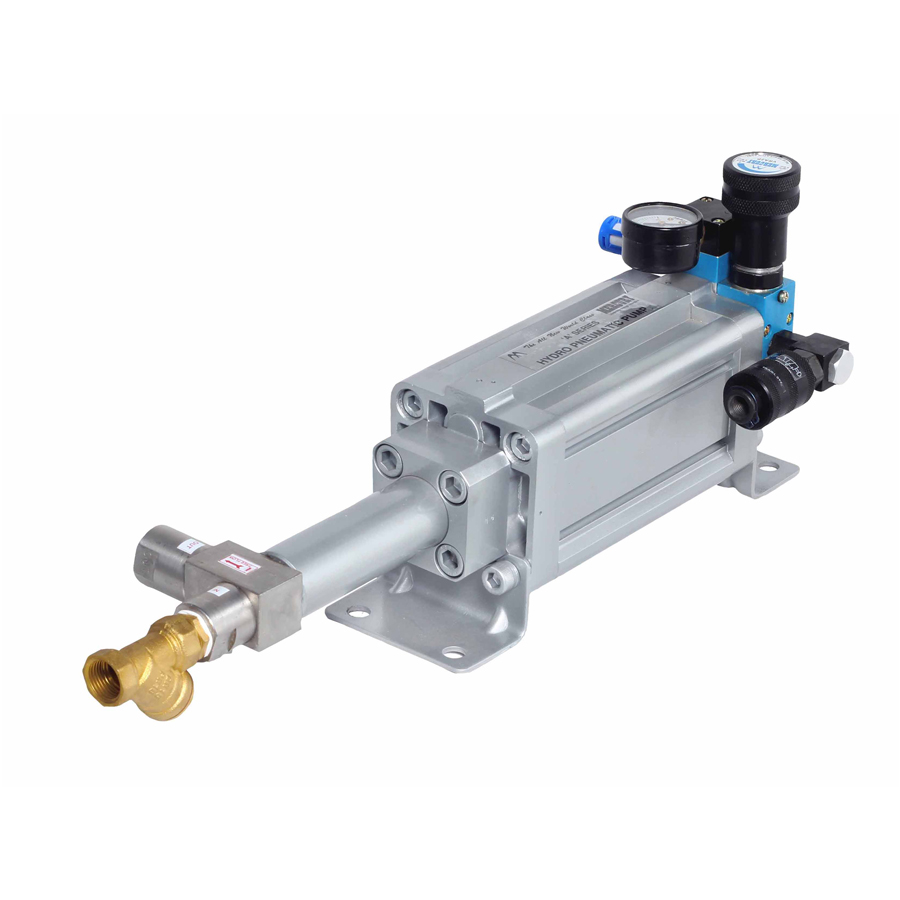

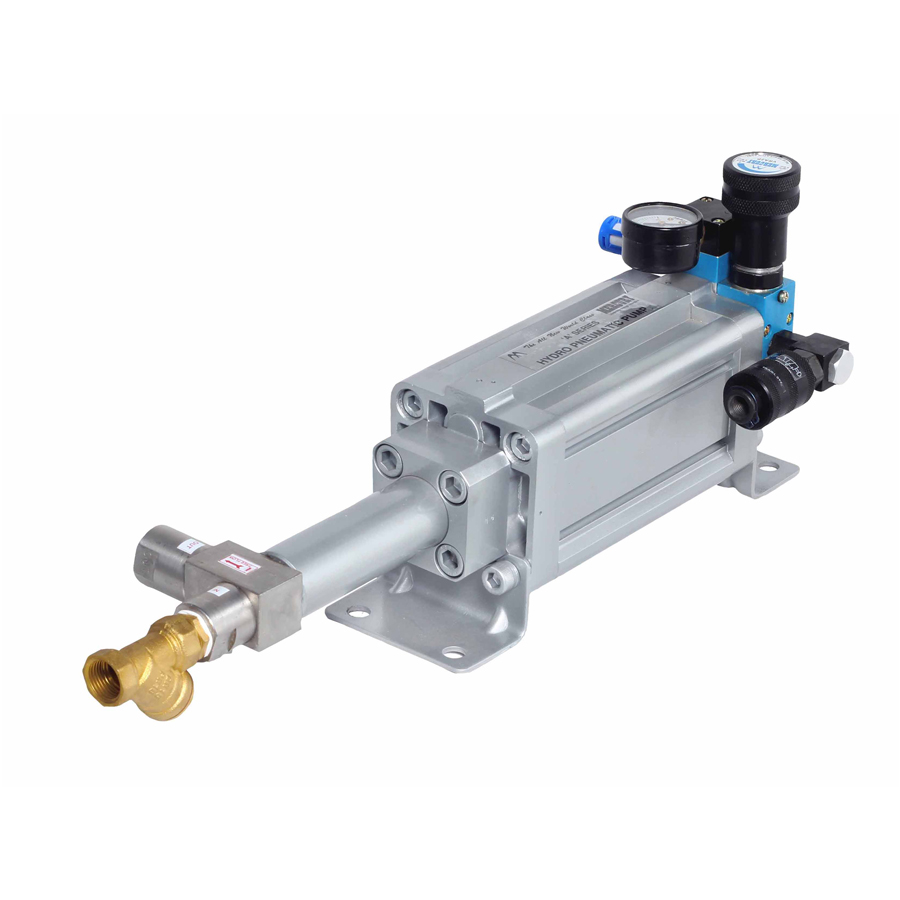

Hydro Pneumatic Pumps

The Mercury New WORLD CLASS Series”A” Hydro-Pneumatic Pumps are an efficient, low cost alternatives to motorized and hand operated pumps. Their salient features are :-

Compact and lightweight and can an be mounted in any orientation.

Low air consumption. When used in conjunction with a low pressure, high discharge centrifugal prefill pump, the energy consumption and time for building desired pressure is very low. Once the pressure has built up there is no further consumption of compressed air.

Automatically compensates for leakages to maintain set pressure.

Can be used in explosive environments as all components are pneumatically actuated.

Designed for use with water and other non corrosive liquids as all wetted parts are made from stainless steel and brass.

Non return valve assembly can be easily dismantled for quick servicing. In low pressure pumps, the discharge port can be rotated through 360°

Precise air pressure regulator with push to lock knob to infinitely vary the output pressure.

Automatic and adjustable lubrication through our AUTOLUBE pump.

Typical applications are:

Hydrostatic pressure testing - Cyclic testing

Burst strength testing

Seat leakage of control valves

Isostatic pressing of powder metals and ceramics

Transferring of liquids from barrels, storage tanks etc.

Pumping oil or grease - Overload protection in mechanical power presses