MECHELONIC ENGINEERS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MECHELONIC ENGINEERS P.LTD.

Press Type Spot Welders

Press type Spot Welders are designed for extra ordinary versatility and are available with different styles of welding head arrangements. These air operated welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. Automatic feed mechanism with X-Y axis and Rotary movements with PLC could be supplied for fast production.

A variety of electrodes and toolings can be fitted to render them suitable for spot welding, simple projection welding, electro-brazing, hot riveting, electro-forging and upsetting.

Fully solid state electronic controls (Microprocessor based or CMOS based) are available for using with machine in order to obtain consistent and accurate weld results on a wide range of materials at a high speed automatic operation.

Bench Mounted Spot Welders

Press type air operated Spot Welders are designed for extra ordinary versatility and are available with different styles of welding head arrangements.

These air operated welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. Automatic feed mechanism with X-Y axis and Rotary movements with PLC could be supplied for fast production. A variety of electrodes and toolings can be fitted to render them suitable for spot welding, simple projection welding, electro-brazing, hot riveting, electro-forging and upsetting.

Press Type Projection Welders

Press type air operated Projection Welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. A variety of electrodes and toolings can be fitted to render them suitable for projection welding, cross wire welding, electro-brazing, hot riveting, electro-forging and upsetting.

Fully solid state electronic controls (Microprocessor based or CMOS based) are available for using with machine in order to obtain consistent and accurate weld results on a wide range of materials at a high-speed automatic operation.

These machines are designed and manufactured conforming to the Indian Standard Specification No.IS:4804 Part I and III by a team of highly experienced engineers in welding technology

Seam Welders

These machines are precision built, with careful design and robust contruction, suitable for long trouble free service. Each machine is submitted to rigorous proving tests before delivery is made, in order that the machine may be ready for immediate installation and operations at customer's works.

The Know-How that enables MECHALONIC ENGINEERS to offer these machines is backed by many years of experience in Welding Technology.

Machines covered under this section are single phase AC for seam welding application in the manufacture of Drums & Barrels, Fuel Tank, silencer, Muffler, Shock Absorber, etc. SPMs AND THREE PHASE D.C. MACHINES : Mechelonic Engineers have in their range a number of SPMs for seam welding applications for jobs, such as fully automatic barrel and shell welding (longitudinal), tub cover welding (circumferential), shock absorber welding, fuel tank welding and other automobile components. Mechelonic Engineers also have seam-welding machine with 3-phase DC transformer and matching controls.

Flash Butt Welders

These machines are robust in construction and are precision-built for long trouble-free service. Each machine is submitted to rigorous proving tests before delivery, so that the machine is ready for immediate installation and operation at the customer's works.

The Know-How that enables MECHALONIC ENGINEERS to offer these machines is backed by many years of experience in Welding Technology.

These Flash Butt Welders are specially designed for heavy duty applications where repeatability in performance is very important. Tooling and clamping devices are available for adapting these machines for the manufacture of railway shackles, automotive parts, starter ring-gears, wheel rims, link chains, etc.

For accurate and consistent weld results fully solid-state electronic controls are provided. Semi-automatic and fully automatic modes of operations are possible. Machine incorporating PLC and SERVO System are also available on request.

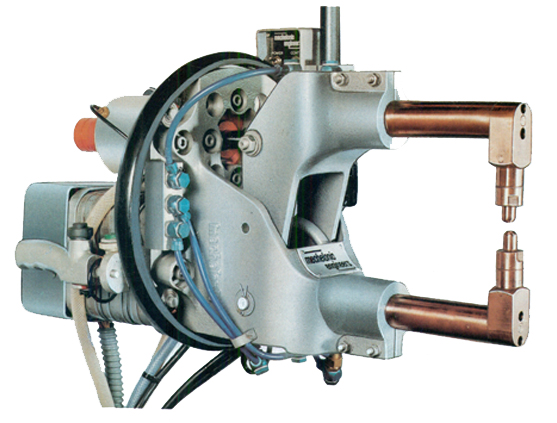

Portable Integral Spot Welding Guns And Welders

Portable Suspension Type Spot Welders are designed for extra ordinary versatility and are available with different styles of welding guns. These air-operated guns are designed for high-speed production to meet the needs of vast number of metal fabrication shops, particularly for the manufacture of automobile bodies and sub-assemblies.

These machines are designed and manufactured conforming to the Indian Standards Specification No. IS 4804 or as per guidelines of JISC-9303 by a team of engineers highly experienced in welding technology.

Micro Head Welders

High performance weld heads built for durability:

Low inertia, fast follow-up designs

Improve weld consistency, reduce metal expulsion, and improve weld appearance

Adjustable force firing

Permits high quality welding since welding force is independent of electrode stroke length

Pneumatic or manual actuation

Configurable according to requirements

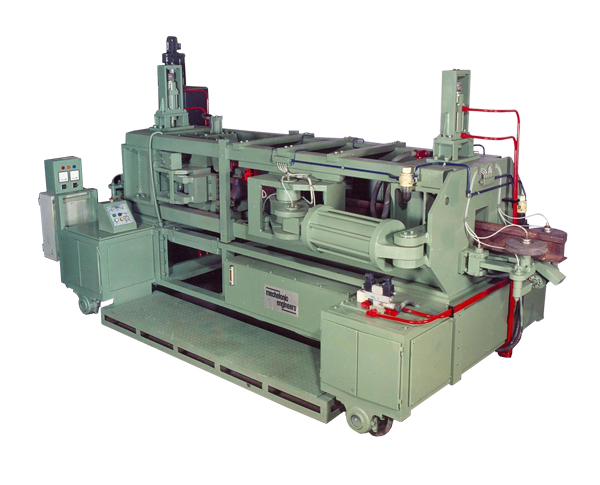

Metal Gathering Machines

Resistance Heating and Upsetting Machines are designed for use in drop forging and valve industry. Generally upsetting can be applied to almost any application calling for the gathering of stock material to enable a component to be produced with the minimum of press works. The perfect “grain-flow” obtained, together with extremely short heating times the upsetting machine is ideal for a variety of jobs and almost in all cases no external or additional heat is required for the subsequent forging operations.

These machines are employed for the production of a wide range of shapes and sizes such as formation of beads, bulbs, collars, stops and flanges on rods as well as tube stock as required in the manufacture of parts like valve heads, bolt heads, control rods, bobbins etc.

A typical application of this machine is to produce upset blanks for the subsequent manufacture of engine valves.

Solidification Machine

Solidification Machine

To heat and solidify copper flexible link manufactured from bunch/stack of copper-foils, used in Electrical and Chemical Industries.

Specifications:

Machine Type :

It is a 3 D. C. Machine. The advantage of this system is low working cost in terms of improved power factor, which can be of the order of 0.9. In addition to this it gives balance load in each phase. Also due to D.C. impendence of secondary circuit dose not come in picture, thus the voltage drop in the system comes down resulting in lower KVA of machine for the same application as compared to single phase A. C. Machine.

The machine is sturdy, all welded steel plate fabrication, and suitably welded and stiffened at points of stress to minimise deflection. The transformer and D.C. Rectifier assembly fitted inside of the body. The pneumatic cylinder mounted on the right hand side to give horizontal movement of the ram guide through precision slides with graphite heating / forging electrodes with water-pump to cool un-heated portions. All internal parts are easily accessible.

Capacitor Discharge Stud Welders

Capacitor Discharge Stud Welders

Capacitor discharge stud welding uses a low voltage capacitor storage system as power source. There are two different welding systems depending on the material:

1. Initial-gap, in which the stud is initially positioned away from the surface of the work-piece. Weld-time is extreme short (<0.001sec).

Wire Mesh Welding Machine

Wire mesh welder is designed for economical manufacture of welded steel wire fabric for general use, confirming to I.S. Specification 1566/4948 as per the welding range specified. The wires for the mesh can be cold drawn or can be galvanized steel wires. However they should be clean and without any rust and oil.

The construction permits the longitudinal wires to be fed directly from spools, automatically pulled as the fabric progresses whereas cross wires cut to length, straightened and fed into longitudinal wires during welding. It is advisable that customer provide a five roller straightener cum stand for proper feeding of long wires.

Brake Shoe Welding Machine

Brake Shoe Welding Machine

This special purpose projection Welding Machine is specially designed for welding brake shoe assemblies. The machine is equipped with basic welding Transformer, Microprocessor based control, pneumatically actuated vertical welding head and special rotary indexing fixture with drives etc. The general layout of the machine is as shown in figure enclosed.

Operation:

The web is located on the rotating fixture and the rim is placed correctly locating its relative position with respect to the web. The welding is initiated by foot-switch. The weld schedule is executed and the fixture automatically indexes to the next projection.

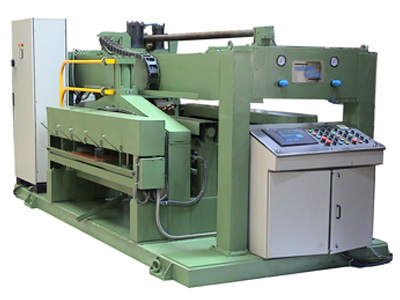

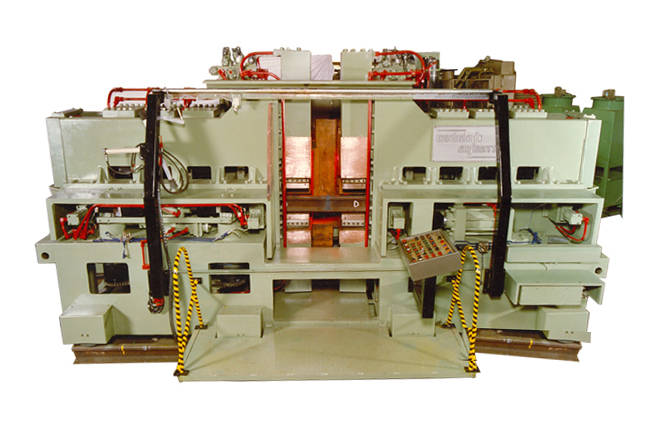

Seam Welder For Steel Mill

This special purpose moving head seam welder is specially designed for steel strip joining in continuous processing plants such as galvanizing plants, coating plants and rolling mills. This machine is primarily used for high speed operation providing minimum pause in line for coil joining. The high strength limited overlap joint produced in the strip is quick and economical for processing.

Construction:

The main frame of the machine consists of a fabricated bridge structure with adequate reinforcement to provide rigidity. The upper beams support and guide the welding head trolley. The lower part supports the shunt and takes up the welding force besides supporting the clamps and other accessories. This designs combines a compact streamlined appearance with maximum resistance to mechanical deflection.

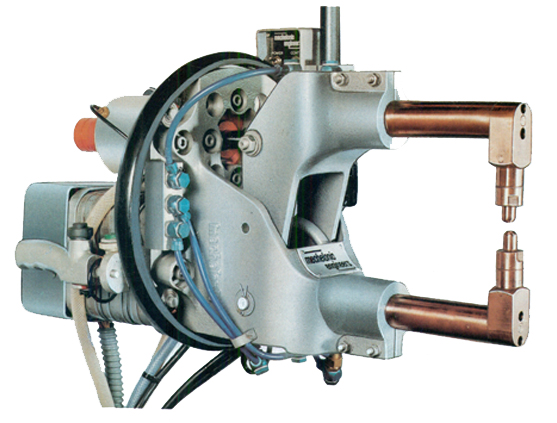

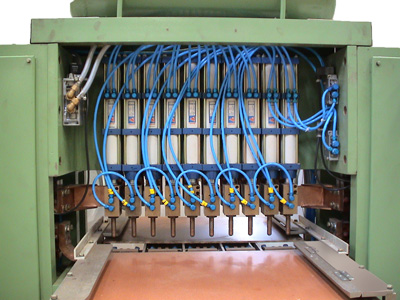

Multi Head Spot Welder

Description / Specification of Multi Head Spot Welder

We are involved in offering a wide range of Multi Head Spot Welder to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Multi Head Spot Welder. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

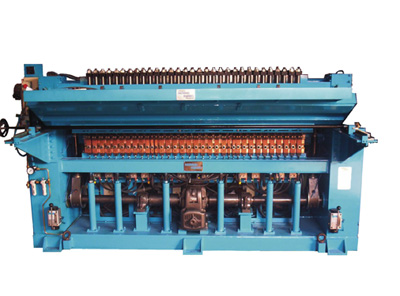

Grating Welding Machines

Grating Welding Machines

Mechelonic Engineers’ Steel Grating Welding machines has been specially designed for the manufacture of steel gratings by electrical resistance welding.

The application on high current and high forging pressure under precise control of a special welding controller and a PLC based sequence controller results in high quality electro forged weld joints that meet the highest standards. the machine can be used for the manufacture of world class gratings using round., square or twisted cross bars.

The machine operation does not require any skilled labour. Apart from the loading of the cross and bearing bars, the machine is completely automatic. The machine comprises of hydraulically operated weld press with cross bar guides and a chain conveyor system. The welding transformers and the secondary systems are designed to ensure high efficiency. The welding parameters are easily settable through a user friendly interface to the control system.

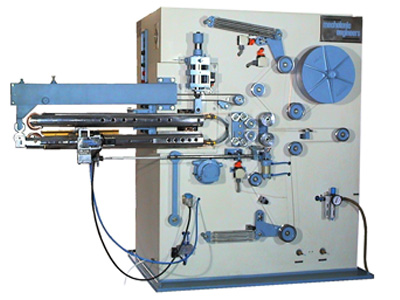

Side Seam Welders

MECHELONIC ENGINEERS Container Side Seam Welding Machine model 18-51 is a trustworthy and economic way of producing consistent, faultless and narrow weld at highest working speeds eliminating need of skilled operator.

Weldability:

The machine is capable of welding a wide range of materials, Tin sheets, Black and TFS sheets (after proper edge cleaning) with thickness ranging from 0.2 to 0.4 mm and body diameters ranging from 52 to 300 mm and body height upto 450 mm depending on the lower arm size.

Body Maker

Mechelonic Engineers has now introduced the second generation, fully automatic container side seam welding machine with medium speed production. Machelonic engineers system of container welding is well established for producing continuous, constant narrow weld at optimum working speed, using copper wire as intermediate electrodes.

Applications

The machine is designed for medium speed automatic welding of tin sheets in container manufacturing. This machine has flexibility of design to accommodate different sizes of cans from 72 to 450mm length(body height)

Handle And Car Lug Welders

Handle & Car Lug Welders

Application Machine Model:

Ear lugs of paint can -- 15-02

Wire handle (chapdi) on can top (upto 5 kg.) -- 15-02

Handle on 5 ltr. rectangular can (one side at a time)-- 15-02

Wire handle (chapdi) on 15 kg. Container -- 15-03

Handles on 5 Kg. rectangular container -- 15-03-01

Stretch Former

Description / Specification of Stretch Former

We are involved in offering a wide range of Stretch Former to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Stretch Former. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Conical Expander

Conical Expander

The machine is used for forming conical shape bodies out of cylindrical form welded bodies. This machine essentially consists of an expanding mandrel which when expanded hydraulically gives the desired conical shape to body.

The round welded body is fed into the mandrel while mandrel is in closed position and on expanding the body takes final desired shape determined by the die. After stretching the mandrel comes back to close from thereby releasing the conical body.

Rail Flash Butt Welders

Description / Specification of Rail Flash Butt Welders

We are involved in offering a wide range of Rail Flash Butt Welders to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Rail Flash Butt Welders. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Rail Grinding Machines

Description / Specification of Rail Grinding Machines

We are involved in offering a wide range of Rail Grinding Machines to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Rail Grinding Machines. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Weld Flash Stripper

Description / Specification of Weld Flash Stripper

We are involved in offering a wide range of Weld Flash Stripper to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Weld Flash Stripper. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.